Plastic Recycling Drying System — High‑Efficiency

Transform washed, wet plastic flakes into high‑value feedstock with moisture consistently below 0.5% using centrifugal dewatering and a thermal dryer — optimised for steady pelletizing and compounding throughput. Seamless downstream integration with our Plastic Pelletizers.

Request a Custom QuoteKey Advantages of Our Drying Technology

Our system is engineered to deliver superior performance, reliability, and the highest return on your investment by focusing on what matters most.

Superior Energy Efficiency

Advanced thermal circulation technology reduces energy consumption by up to 30% compared to conventional dryers.

Ultra-Low Moisture Content

Achieves a final moisture level consistently below 0.5%, meeting stringent requirements for pelletizing and molding.

Fully Automated Operation

PLC intelligent control allows for one-touch start-up and continuous, unattended operation, minimizing labor costs.

Eco-Friendly Design

A fully enclosed system prevents dust and vapor leakage, ensuring compliance with modern environmental standards.

How the Plastic Recycling Drying System Works

We've refined the drying process into four efficient, automated stages to guarantee optimal results with minimal oversight.

Step 1: Feeding

Washed, wet plastic flakes are automatically conveyed into the main drying chamber.

Step 2: Centrifugal De‑watering

High-speed rotation generates centrifugal force to mechanically remove surface moisture.

Step 3: Thermal Drying

A hot air circulation system thoroughly and uniformly heats the material to evaporate residual moisture.

Step 4: Discharge

Dry, purified plastic material is automatically discharged, ready for bagging or the next production stage.

Core Components & Technical Features

Every component is selected for durability, performance, and ease of maintenance, ensuring your production line runs smoothly.

Stainless Steel Construction

All parts in contact with material are made of SUS304 stainless steel to prevent corrosion and ensure raw material purity.

Variable Frequency Drive (VFD) Motor

Allows for adjustable rotation speed to optimize drying performance and energy efficiency for different types of plastics.

Precision Temperature Control

Monitors and regulates internal temperature in real-time, preventing material degradation or discoloration from overheating.

System in Action: Video Demonstration

Watch our drying system efficiently process plastic materials, showcasing its speed, automation, and the quality of the final product.

Demo highlights: centrifugal de‑watering → thermal drying → cyclone discharge. Typical flakes exit under 0.5% moisture, ready for stable pelletizing.

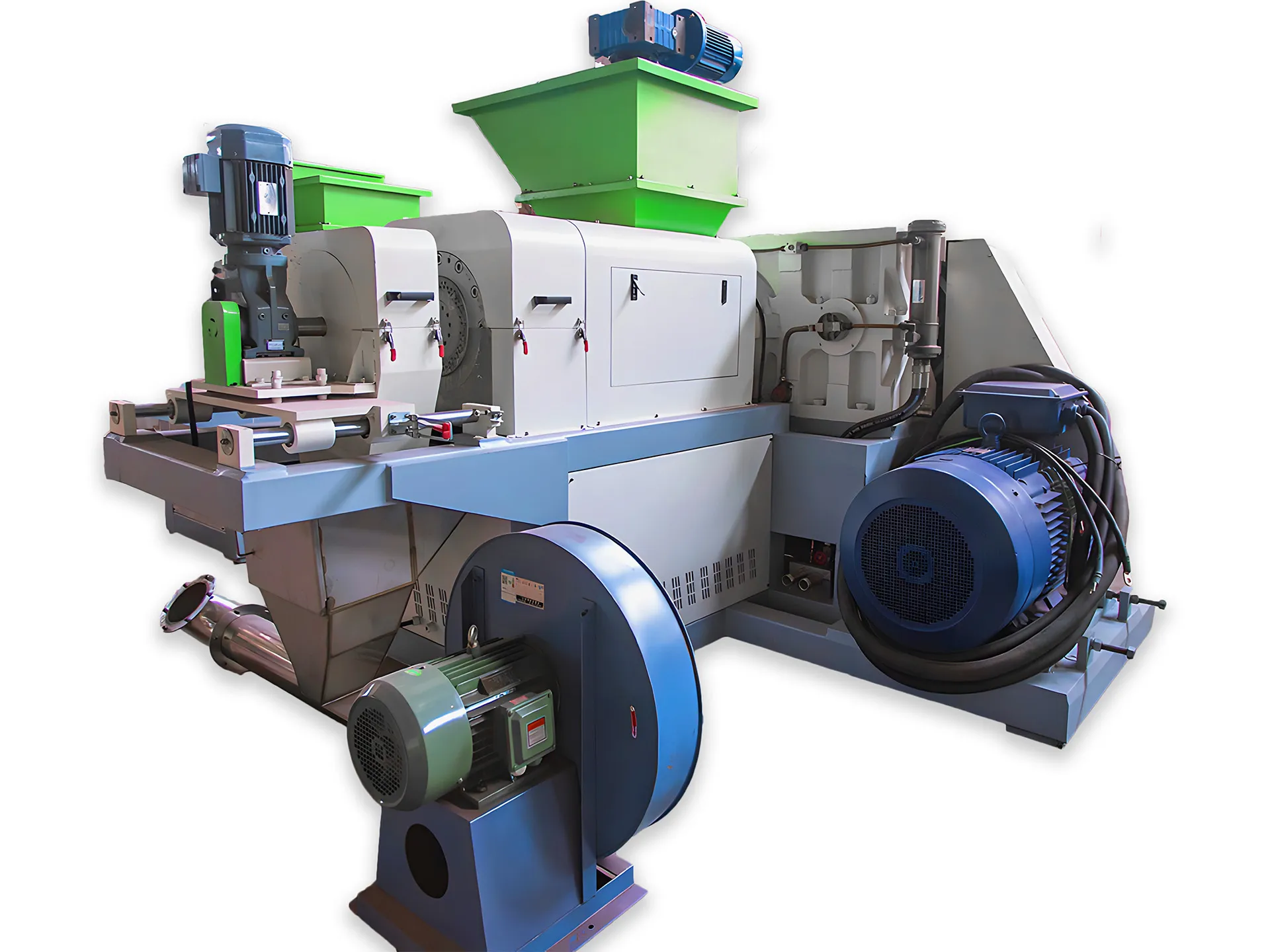

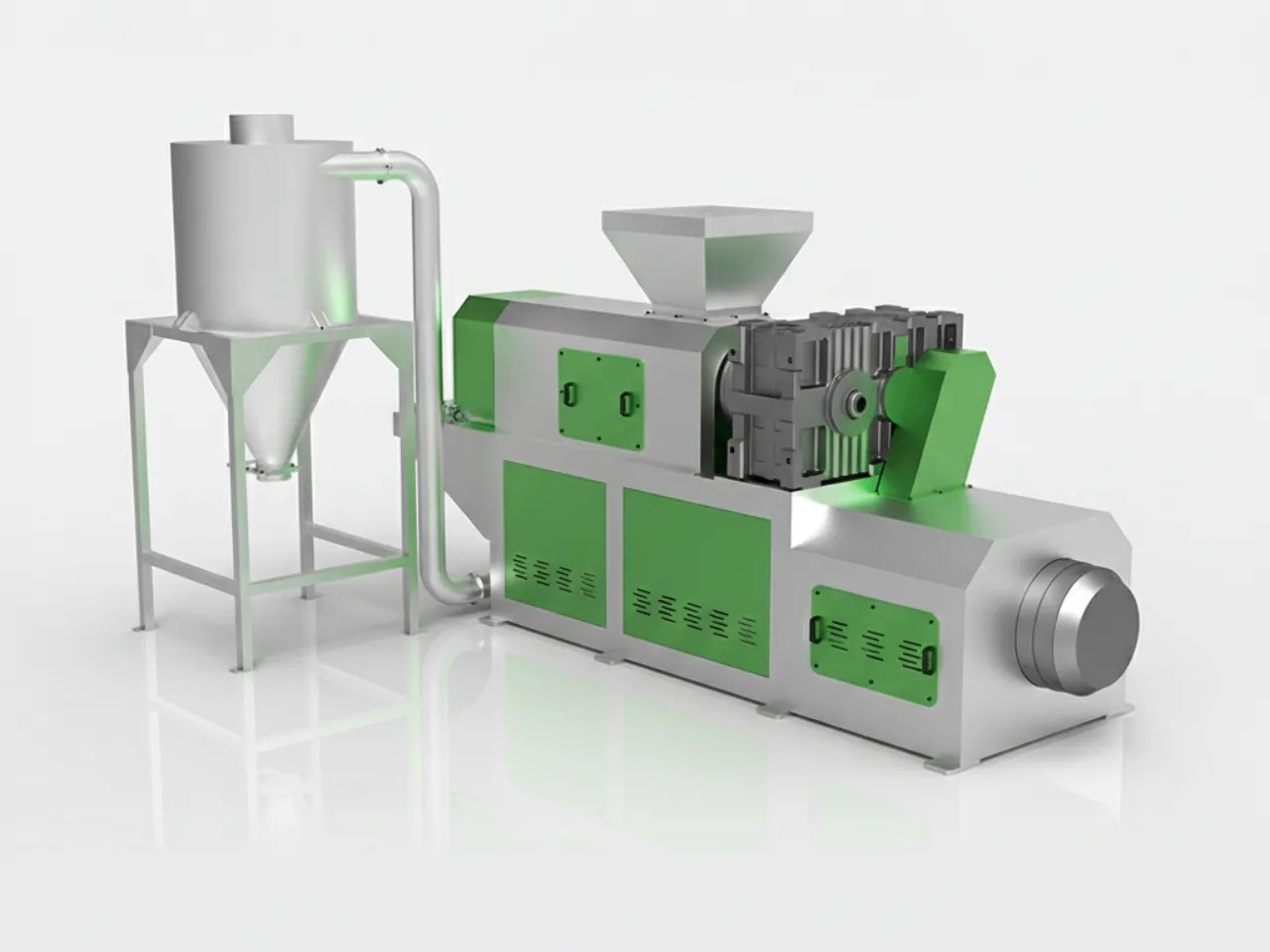

Equipment Gallery

Explore high-resolution images of our drying system components, highlighting the quality of construction and engineering.

Frequently Asked Questions

Find answers to common questions about our plastic recycling drying system.

What types of plastic can this system process?

Our drying system is versatile and can efficiently handle a wide range of rigid and flexible plastics, including PET flakes, HDPE, LDPE film, PP woven bags, ABS, and more. We can customize the equipment based on your specific material.

Is the installation and commissioning process complex?

The system features a modular design for easy installation. We provide detailed installation manuals and remote video support. On-site engineering services for installation, commissioning, and operator training are also available to ensure a smooth start-up.

What are the maintenance requirements?

Routine maintenance is straightforward and primarily involves periodic cleaning of the screen mesh and checking bearing lubrication. A comprehensive maintenance checklist is provided. Thanks to high-quality, durable components, the system has a very low failure rate.

How can I get detailed technical specifications and a quote?

Please use the inquiry form below or contact us directly. Our sales engineers will promptly connect with you to understand your requirements (e.g., capacity, material type) and provide a tailored technical proposal and quotation.

Get Your Custom Solution & Quote

Contact us today to receive a customized quote and detailed technical proposal for a drying system that fits your specific needs.