Our screw press dewatering system, engineered specifically for our PE film washing line, is a highly effective method for extracting moisture from a material stream. In fact, our screw presses are frequently utilized in food processing, paper & pulp industries, sewage treatment, and more. This durable piece of machinery provides outstanding moisture reduction without the substantial cost (electricity expense) of operating thermal heaters.

Working principle

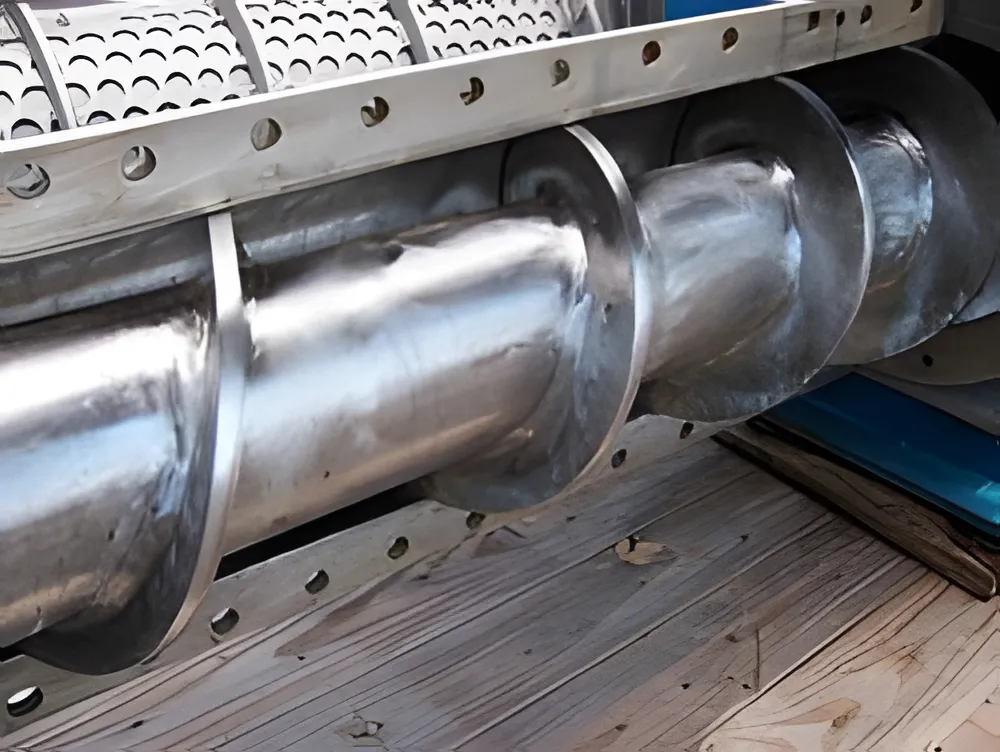

At the core of our screw press dewatering system is a screw shaft with a progressively increasing diameter. The screw shaft is narrowest at the entry point where the plastic material is introduced via the vertical feeder. Surrounding the screw shaft is a thick-walled, uniform diameter outer tube lined with perforations for water drainage. The typical dewatering screw press for industrial recycling applications is 4-6 meters in length but can be adjusted according to your requirements.

As the wet plastic feed stock is introduced into the feeder, the screw shaft gradually rotates, advancing the plastic forward. As the screw shaft’s diameter increases, the plastic becomes increasingly compacted against the outer casing wall. The moisture from the plastic material is squeezed out and drains through the small perforations.

At the conclusion of the horizontal screw press, the screw shaft’s diameter is only slightly smaller than the inner diameter of the outer casing. It is through this narrow gap that the dried plastic material exits the screw press. A well-designed screw press will reduce moisture content to acceptable levels below 15%.

Additional Images

Inquire Now

To get the latest prices and lead times, send us a message using the form below.