Vertikal Pencampuran & Pengeringan Mesin

Unit yang ringkas dan berkinerja tinggi yang mencampur bubuk atau butiran dan menghilangkan kelembapan menggunakan pemanasan dan aliran udara terkontrol—ideal untuk pemrosesan plastik dan persiapan material industri.

Fitur Utama

Dirancang untuk pencampuran yang stabil, pengeringan yang efisien, dan pengoperasian yang mudah—dibuat dengan mempertimbangkan daya tahan industri.

- Desain Tangki Vertikal

Tangki silinder vertikal dengan dasar kerucut untuk pencampuran dan pengeluaran yang efisien, dengan ukuran yang ringkas.

- Bahan Tahan Lama

Umumnya dibuat dengan baja tahan karat anti korosi untuk menahan lingkungan industri yang berat.

- Pemanasan & Pengeringan

Sistem pemanas terintegrasi mendukung penghilangan kelembapan dan pemrosesan yang stabil untuk material yang sensitif terhadap suhu.

- Sistem pengaturan

Tetapkan dan pantau parameter seperti suhu, kecepatan pengadukan, dan waktu untuk mendapatkan hasil yang konsisten.

- Perlindungan Keamanan

Tombol berhenti darurat dan pengunci pengaman membantu melindungi operator dan mengurangi risiko operasional.

- Aksesori Opsional

Opsi seperti nosel semprot untuk pemberian dosis cairan atau dukungan vakum untuk penghilangan udara dapat ditambahkan.

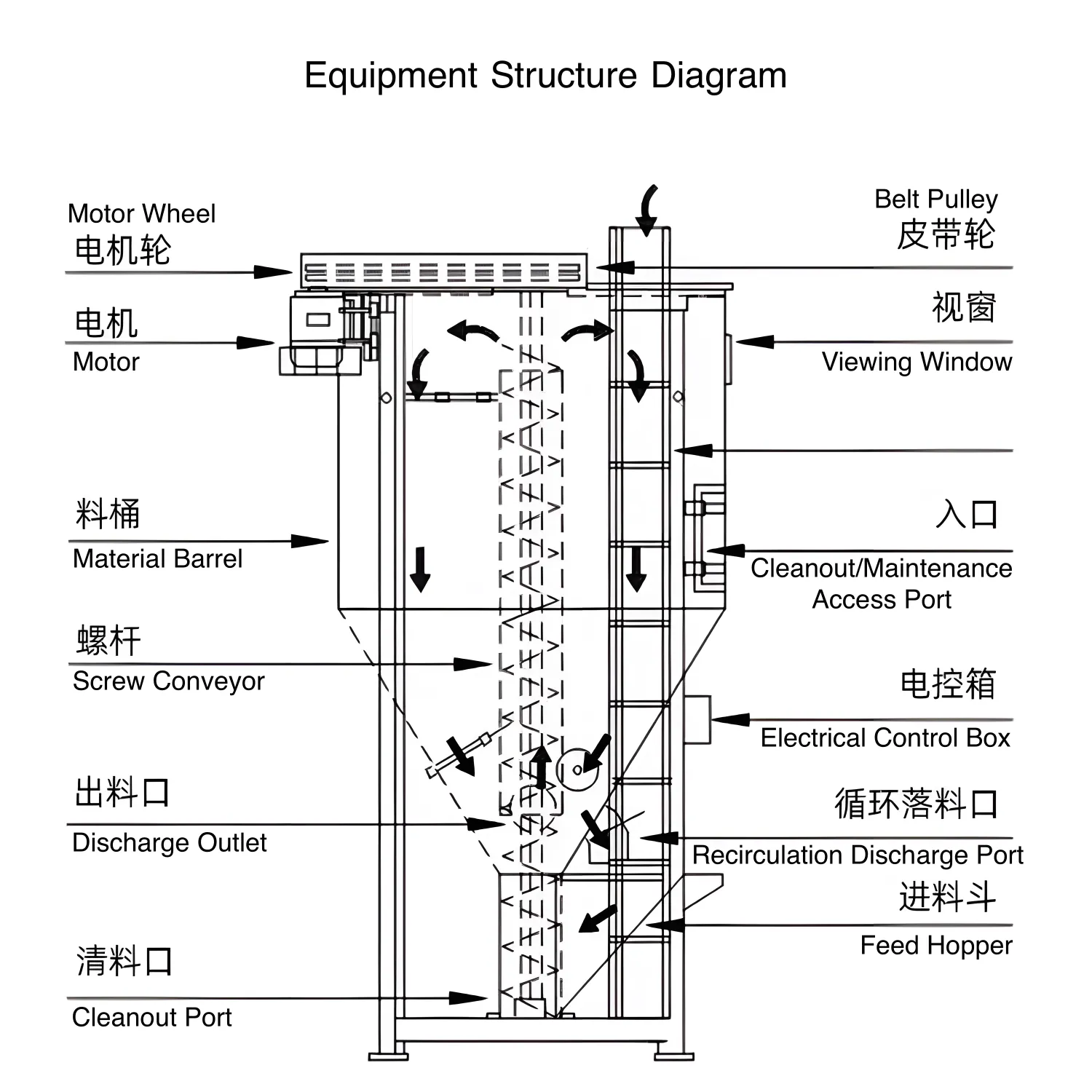

Cara Kerjanya: Pencampuran + Pengeringan dalam Satu Proses

Alur kerja sederhana 3 langkah yang mencampur bahan secara seragam, menghilangkan kelembapan menggunakan pemanasan + aliran udara, dan membuang hasil akhir dengan bersih untuk proses selanjutnya.

- 1) Memberi Makan

Masukkan bubuk, butiran, pelet, atau serpihan ke dalam ruang vertikal—pengaturan dosis opsional mendukung kontrol batch yang stabil.

- 2) Pencampuran

Sistem pencampuran mengalirkan material ke seluruh tangki untuk meningkatkan keseragaman, ideal untuk mencampur aditif atau masterbatch.

- 3) Pemanasan, Pengeringan & Pembuangan

Pemanasan terkontrol dengan sirkulasi udara panas menghilangkan kelembapan, kemudian bagian bawah berbentuk kerucut mendukung pembuangan yang cepat dan bersih ke peralatan hilir.

Parameter teknik

Spesifikasi referensi untuk konfigurasi standar. Kami mendukung kustomisasi berdasarkan kebutuhan material dan lokasi.

| Nama | Spesifikasi |

|---|---|

| Volume | 3000 L |

| Kekuatan | 4 kW |

| Kekuatan Pemanasan | 42 kW |

| Kipas / Blower | 2,2 kW |

| Ketebalan Pelat | 2,5 mm |

| Spesifikasi Spindel | φ60 × 4 |

| Ketebalan Pisau | 3 mm |

| Diameter Sekrup | φ273 |

| Berat Peralatan | 700kg |

| Ukuran | P1900 × L2300 × T3100 |

Aplikasi

Cocok untuk bubuk, butiran, dan material ringan di seluruh industri plastik dan manufaktur umum.

- Pengolahan Plastik

Mencampur dan mengeringkan pelet, serpihan, atau hasil daur ulang plastik untuk proses ekstrusi atau pencetakan selanjutnya yang stabil.

- Industri Kimia

Mencampur dan mengeringkan senyawa kimia untuk mencapai pencampuran yang konsisten dan pengendalian kadar air.

- Makanan & Minuman

Mencampur rempah-rempah dan bubuk sambil mengurangi kadar air untuk konsistensi dan pengawetan yang lebih baik.

- Farmasi & Kosmetik

Pencampuran bahan secara homogen dan pengeringan terkontrol untuk memenuhi persyaratan proses.

Manfaat

Sebuah mesin tunggal yang meningkatkan kapasitas produksi, konsistensi, dan efisiensi operasional.

- Efisiensi Lebih Tinggi

Menggabungkan pencampuran dan pengeringan dalam satu unit untuk mengurangi waktu penanganan dan menyederhanakan alur kerja Anda.

- %%

Meningkatkan homogenitas dan stabilitas kelembapan untuk pemrosesan hilir yang andal.

- Hemat energi

Desain termal dan aliran udara yang dioptimalkan membantu mengurangi biaya operasional secara keseluruhan.

- Ukuran Kecil

Orientasi vertikal menghemat ruang lantai sekaligus mempertahankan volume kerja.

Galeri Gambar

Pemeliharaan & Perawatan

Inspeksi dan pembersihan rutin membantu memastikan output yang stabil dan masa pakai yang lama.

- Pemeriksaan Rutin

Periksa komponen-komponen utama, elemen pemanas, dan pengaman secara berkala.

- Pelumasan

Lakukan perawatan pada bantalan dan bagian yang bergerak dengan pelumasan yang tepat untuk mengurangi keausan dan kebisingan.

- Pembersihan

Bersihkan ruang tersebut setelah proses produksi selesai untuk mencegah penumpukan dan kontaminasi silang.

- Kalibrasi

Periksa pengaturan suhu dan waktu untuk kinerja pengeringan yang konsisten.

Pertanyaan yang Sering Diajukan

Produk ini cocok untuk berbagai bubuk dan butiran, termasuk pelet/serpihan plastik, senyawa kimia, dan bubuk makanan atau farmasi tertentu. Beri tahu kami jenis material dan tingkat kelembapannya untuk konfirmasi.

Ya. Desain pencampuran vertikal mendukung pencampuran yang konsisten. Kami dapat merekomendasikan kecepatan/waktu pencampuran berdasarkan kepadatan curah dan persentase aditif.

Pemilihan bergantung pada ukuran batch, target throughput, kadar air, dan ruang instalasi yang tersedia. Bagikan detail proses Anda dan kami akan mengusulkan konfigurasi yang sesuai.

Kami mendukung standar daya industri umum dan dapat menyesuaikannya untuk wilayah Anda. Berikan tegangan/frekuensi dan tata letak lokasi Anda untuk mengkonfirmasi pemasangan kabel dan peralatan bantu.

Kami menyarankan untuk membersihkan ruang pembakaran setelah produksi dan mengikuti rencana inspeksi/pelumasan rutin. Panduan perawatan dan daftar suku cadang tersedia.

Ya. Kami menawarkan opsi pemasangan jarak jauh atau di lokasi, pelatihan operator, dan dukungan purna jual dengan suku cadang yang direkomendasikan untuk perawatan cepat.

Tanyakan Sekarang

Sebutkan jenis material Anda, kapasitas target, dan standar daya—tim kami akan merekomendasikan solusi terbaik.