Plastic Recycling Drying System High-Efficiency

Transform washed wet plastic flakes into high-value feedstock with moisture consistently below 0.5% using centrifugal dewatering and thermal drying. This line integrates smoothly with our Plastic Pelletizers.

Request a Custom QuoteKey Advantages of Our Drying Technology

The system focuses on low energy use, stable moisture control, automation, and clean operation for consistent production results.

Superior Energy Efficiency

Advanced thermal circulation reduces energy consumption by up to 30% compared with conventional drying setups.

Ultra-Low Moisture Content

Final moisture stays below 0.5%, meeting strict requirements for pelletizing, molding, and compounding.

Fully Automated Operation

PLC intelligent control supports one-touch startup and stable unattended running with lower labor demand.

Eco-Friendly Design

Fully enclosed structure limits dust and vapor leakage to meet modern environmental compliance targets.

How the Plastic Recycling Drying System Works

The process runs in four linked stages from feeding to dry output for reliable downstream operation.

Step 1: Feeding

Washed wet plastic flakes are conveyed into the drying section automatically.

Step 2: Centrifugal Dewatering

High-speed rotation removes surface water mechanically before thermal treatment.

Step 3: Thermal Drying

Hot air circulation evaporates residual moisture evenly without overheating material.

Step 4: Discharge

Dry purified material is discharged automatically for bagging or the next process stage.

Core Components and Technical Features

Each module is selected for durability, stable performance, and easier maintenance.

Stainless Steel Construction

Material-contact parts use SUS304 stainless steel to reduce corrosion risk and maintain feedstock purity.

VFD Motor Control

Adjustable rotation speed helps optimize drying performance and power use for different plastics.

Precision Temperature Control

Real-time temperature regulation protects material quality and prevents overheating discoloration.

System in Action Video Demonstration

Demo highlights include centrifugal dewatering, thermal drying, and cyclone discharge with stable low-moisture output.

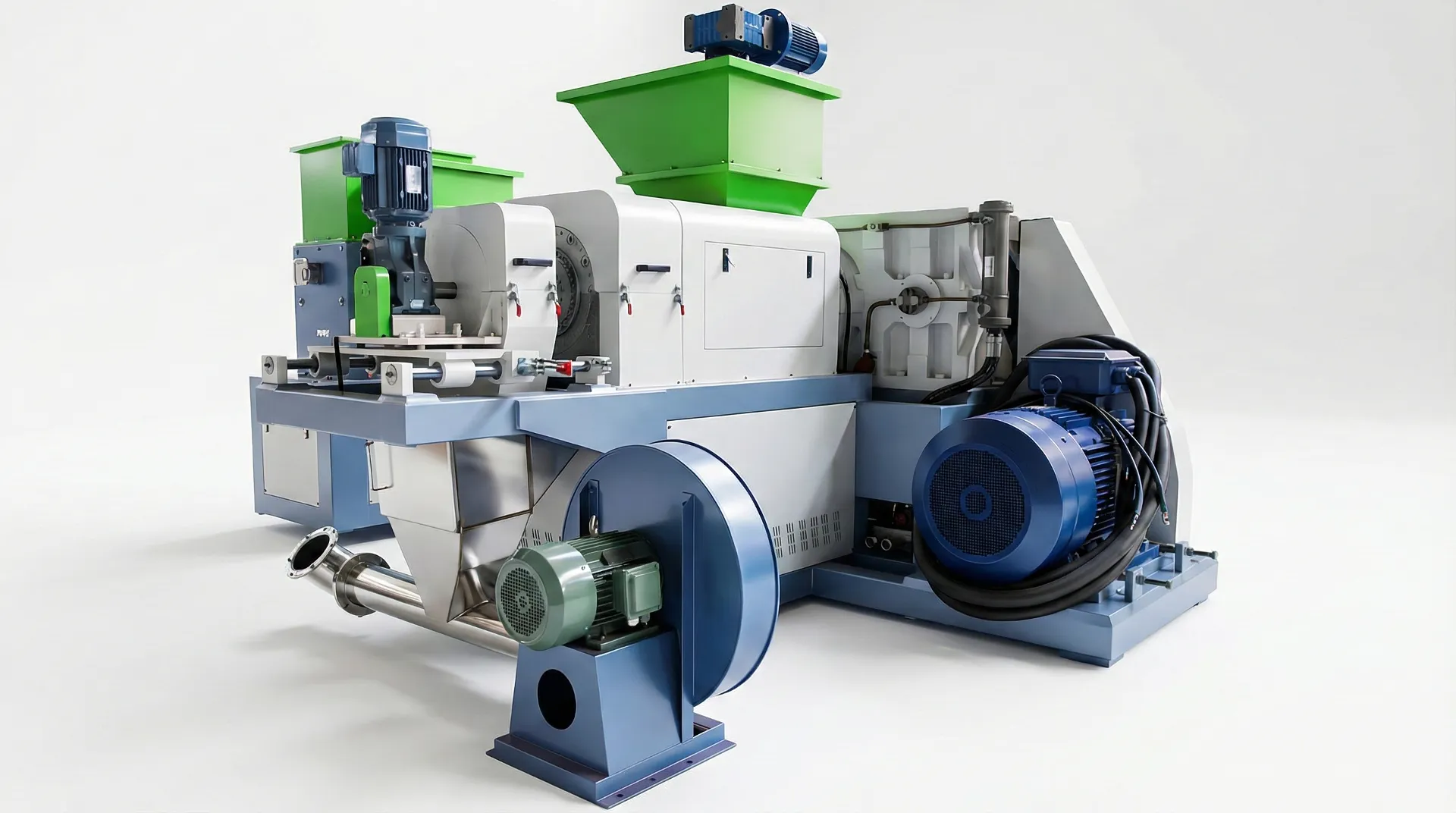

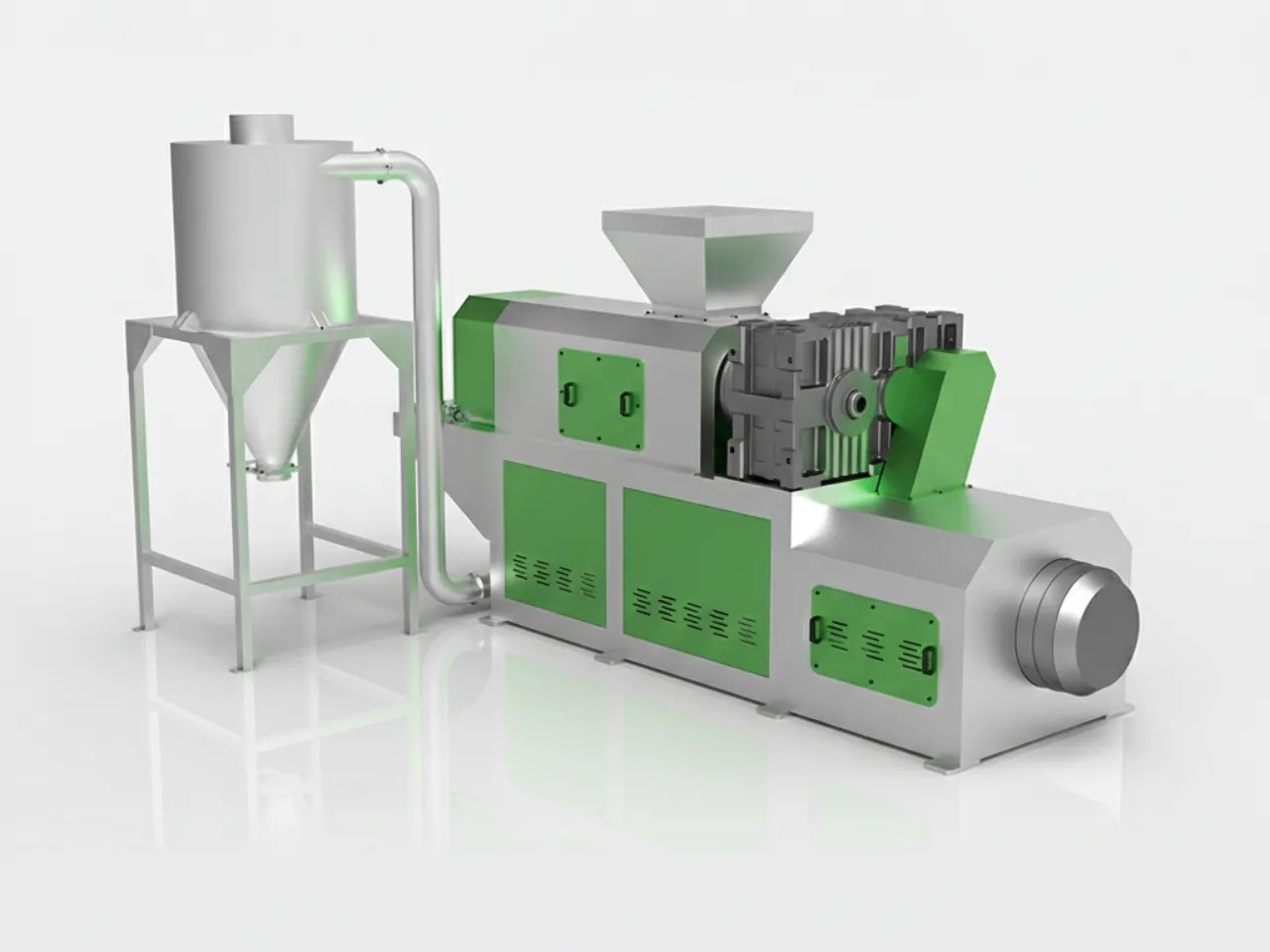

Equipment Gallery

High-resolution equipment images show construction quality and process module details.

Frequently Asked Questions

Common questions on material compatibility, maintenance, installation, and quotation.

The drying system can process PET flakes, HDPE and LDPE film, PP woven materials, ABS, and other rigid or flexible plastics. Configuration can be tuned to your material type and moisture target.

The system is modular for easier installation. We provide manuals, remote video support, and optional on-site commissioning and operator training.

Routine work mainly includes cleaning screen mesh, checking lubrication points, and verifying airflow and temperature settings. Durable components keep failure rates low.

Use the inquiry form below or contact us directly with capacity, material, and moisture requirements. Our team will provide a tailored proposal and quotation.

Get Your Custom Solution and Quote

Contact us for a customized drying system proposal that matches your production and quality targets.