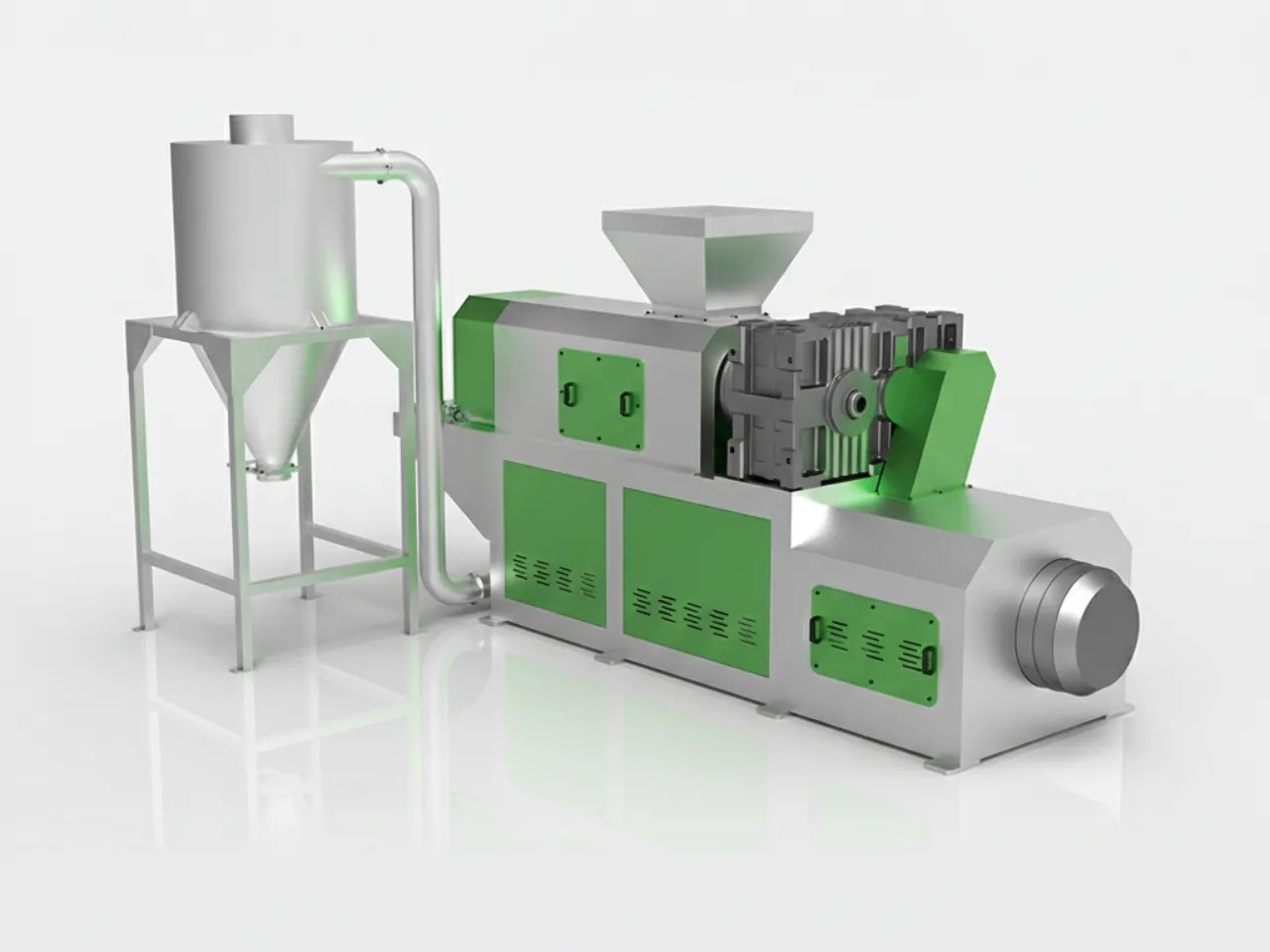

How the Plastic Film Screw Press System Streamlines Recycling Operations

Unlock Peak Efficiency: How a Plastic Film Screw Press Transforms Your Recycling Line In the world of plastic recycling, moisture is the enemy. It drives up energy costs, slows down processing, and compromises the qu...