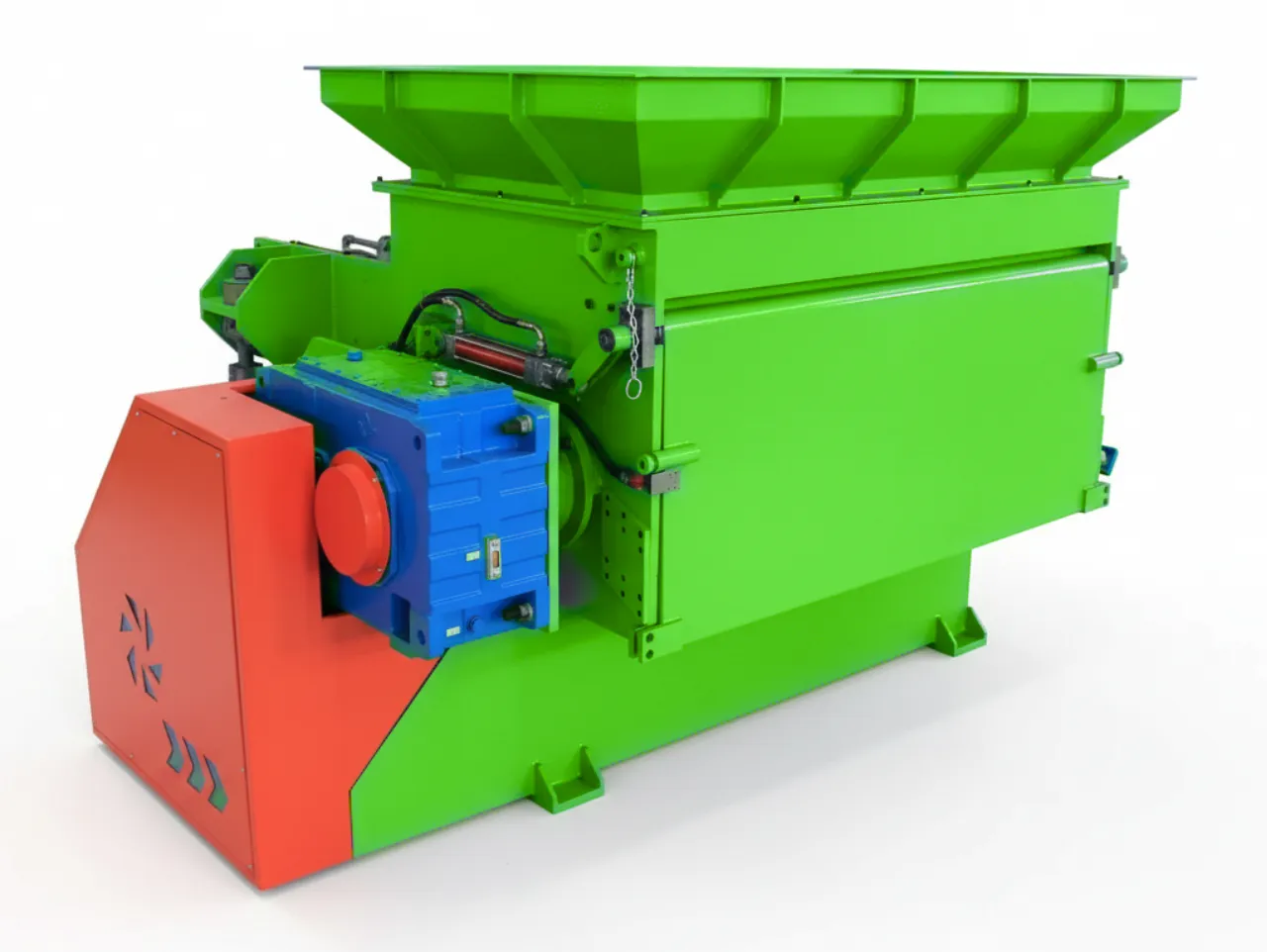

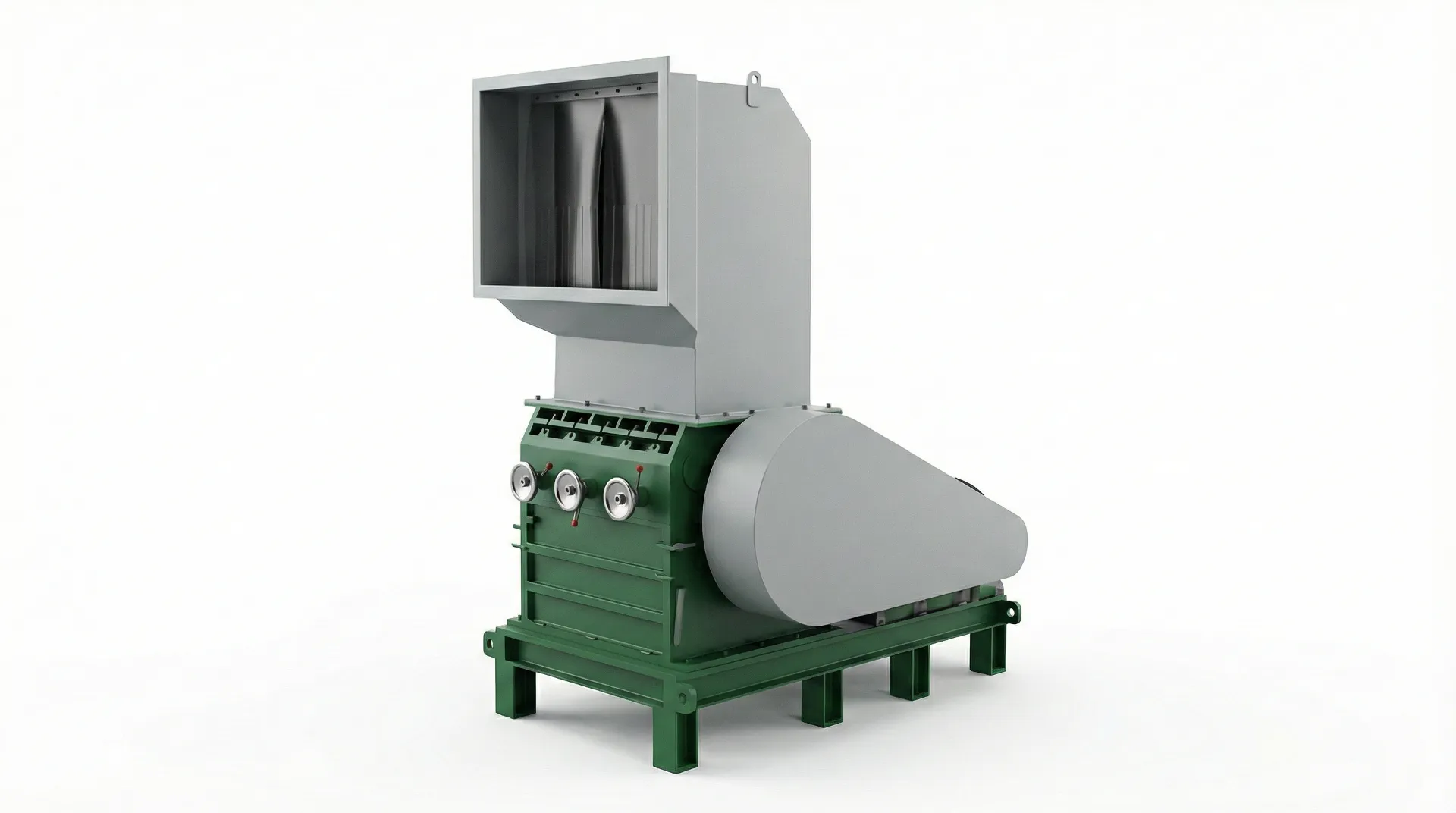

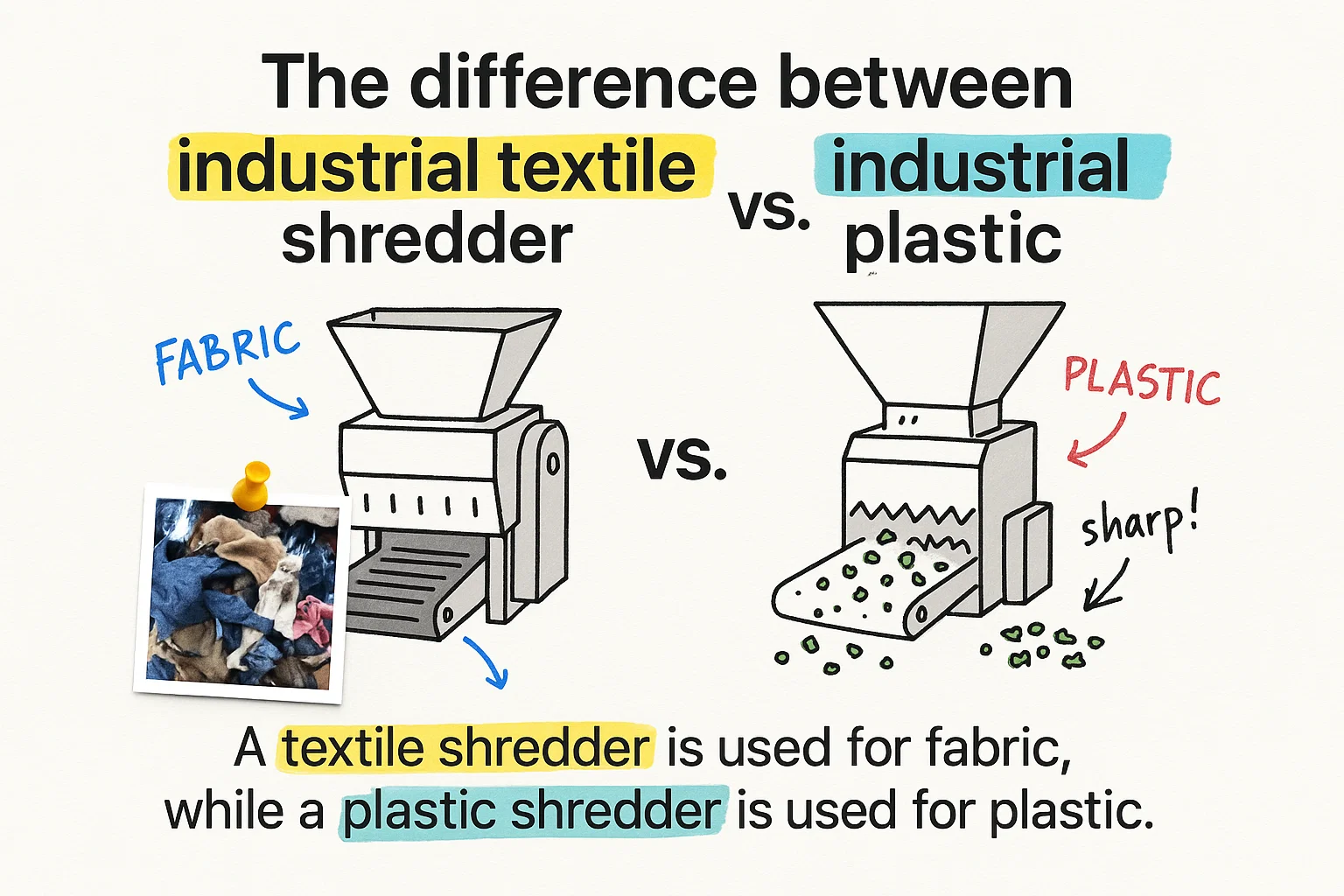

The difference between textile shredder and standard shredder

The difference between textile shredder and standard shredder becomes critical when you’re processing materials that demand specialized cutting mechanisms. Textile waste requires unique shredding capabilities that standard i...