Vertical Mixing & Drying Maşină

A compact, high-efficiency unit that blends powders or granules and removes moisture using controlled heating and airflow—ideal for plastics processing and industrial material preparation.

Caracteristici cheie

Designed for stable mixing, efficient drying, and easy operation—built with industrial durability in mind.

- Vertical Tank Design

Vertical cylindrical tank with conical bottom for efficient mixing and discharge, with a compact footprint.

- Durable Materials

Commonly built with corrosion-resistant stainless steel to withstand demanding industrial environments.

- Heating & Drying

Integrated heating system supports moisture removal and stable processing for temperature-sensitive materials.

- Sistem de control

Set and monitor parameters like temperature, mixing speed, and time for repeatable results.

- Protecție de siguranță

Emergency stop and safety interlocks help protect operators and reduce operational risk.

- Optional Accessories

Options like spray nozzles for liquid dosing or vacuum support for deaeration can be added.

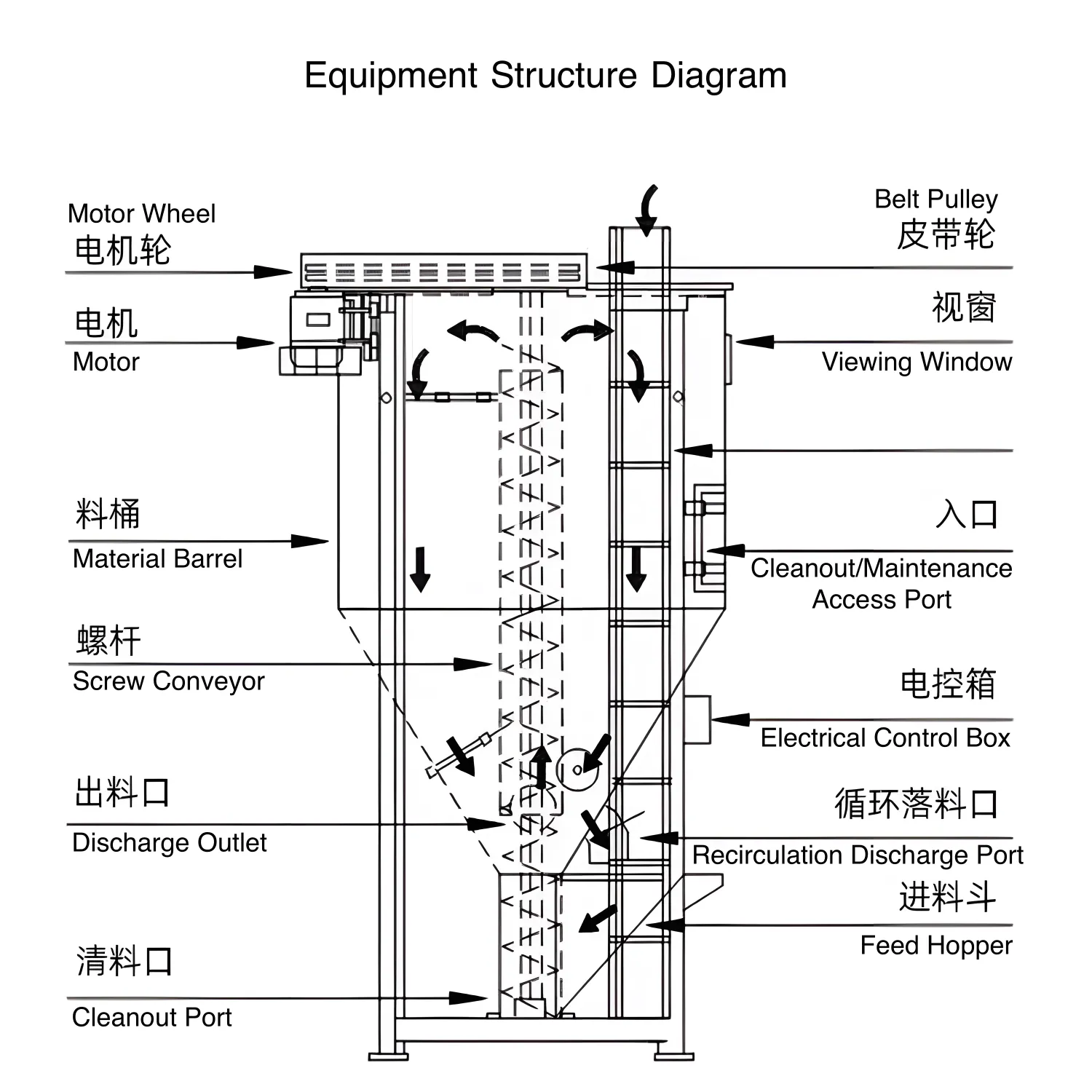

How It Works: Mixing + Drying in One

A simple 3-step workflow that blends materials uniformly, removes moisture using heating + airflow, and discharges cleanly for the next process.

- 1) Hrănire

Load powder, granules, pellets, or flakes into the vertical chamber—optional dosing supports stable batch control.

- 2) Amestecare

The mixing system circulates materials throughout the tank to improve uniformity, ideal for blending additives or masterbatch.

- 3) Heating, Drying & Discharge

Controlled heating with hot-air circulation removes moisture, then the conical bottom supports fast, clean discharge to downstream equipment.

Parametri tehnici

Reference specifications for a standard configuration. We support customization based on material and site requirements.

| Nume | Specificații |

|---|---|

| Volum | 3000 L |

| Putere | 4 kW |

| Putere de încălzire | 42 kW |

| Fan / Blower | 2,2 kW |

| Grosimea farfuriei | 2.5 mm |

| Specificații ax | φ60 × 4 |

| Grosimea lamei | 3 mm |

| Diametrul șurubului | φ273 |

| Greutatea echipamentului | 700 kg |

| Dimensiuni | L1900 × W2300 × H3100 |

Aplicații

Suitable for powders, granules, and lightweight materials across plastics and general manufacturing.

- Plastics Processing

Mixing and drying plastic pellets, flakes, or regrind for stable downstream extrusion or molding.

- Chemical Industry

Mixing and drying chemical compounds to achieve consistent blending and moisture control.

- Food & Beverage

Mixing spices and powders while reducing moisture for better consistency and preservation.

- Pharma & Cosmetics

Homogeneous mixing of ingredients and controlled drying to meet process requirements.

Beneficii

A single machine that improves throughput, consistency, and operating efficiency.

- Higher Efficiency

Combines mixing and drying into one unit to reduce handling time and simplify your workflow.

- %%

Improves homogeneity and moisture stability for reliable downstream processing.

- Economie de energie

Optimized thermal and airflow design helps reduce overall operating costs.

- Piesă compactă

Vertical orientation saves floor space while maintaining working volume.

Galerie de Imagini

Maintenance & Care

Routine inspection and cleaning help ensure stable output and long service life.

- Routine Checks

Inspect key components, heating elements, and safety interlocks on a regular schedule.

- Lubrifiere

Maintain bearings and moving parts with proper lubrication to reduce wear and noise.

- Curatenie

Clean the chamber after production runs to prevent buildup and cross-contamination.

- Calibration

Verify temperature and timing settings for consistent drying performance.

întrebări frecvente

It’s suitable for many powders and granules, including plastic pellets/flakes, chemical compounds, and certain food or pharma powders. Tell us your material type and moisture level for confirmation.

Yes. The vertical mixing design supports consistent blending. We can recommend mixing speed/time based on bulk density and additive percentage.

Selection depends on batch size, target throughput, moisture content, and available installation space. Share your process details and we’ll propose a suitable configuration.

We support common industrial power standards and can customize for your region. Provide your voltage/frequency and site layout to confirm wiring and auxiliary equipment.

We recommend cleaning the chamber after production and following a routine inspection/lubrication plan. A maintenance guide and spare-parts list are available.

Yes. We offer remote or on-site commissioning options, operator training, and after-sales support with recommended spare parts for quick maintenance.

Întrebați acum

Tell us your material type, target capacity, and power standard—our team will recommend the best solution.