Vertical Mistura e Secagem Máquina

Uma unidade compacta e de alta eficiência que mistura pós ou grânulos e remove a umidade usando aquecimento e fluxo de ar controlados — ideal para processamento de plásticos e preparação de materiais industriais.

Características principais

Projetada para mistura estável, secagem eficiente e operação fácil — construída com durabilidade industrial em mente.

- Projeto de tanque vertical

Tanque cilíndrico vertical com fundo cônico para mistura e descarga eficientes, com dimensões compactas.

- Materiais duráveis

Geralmente fabricados em aço inoxidável resistente à corrosão para suportar ambientes industriais exigentes.

- Aquecimento e Secagem

O sistema de aquecimento integrado auxilia na remoção da umidade e no processamento estável de materiais sensíveis à temperatura.

- Sistema de controle

Defina e monitore parâmetros como temperatura, velocidade de mistura e tempo para obter resultados consistentes.

- Proteção de Segurança

Os sistemas de parada de emergência e intertravamento de segurança ajudam a proteger os operadores e a reduzir os riscos operacionais.

- Acessórios opcionais

É possível adicionar opções como bicos de pulverização para dosagem de líquidos ou suporte de vácuo para desaerificação.

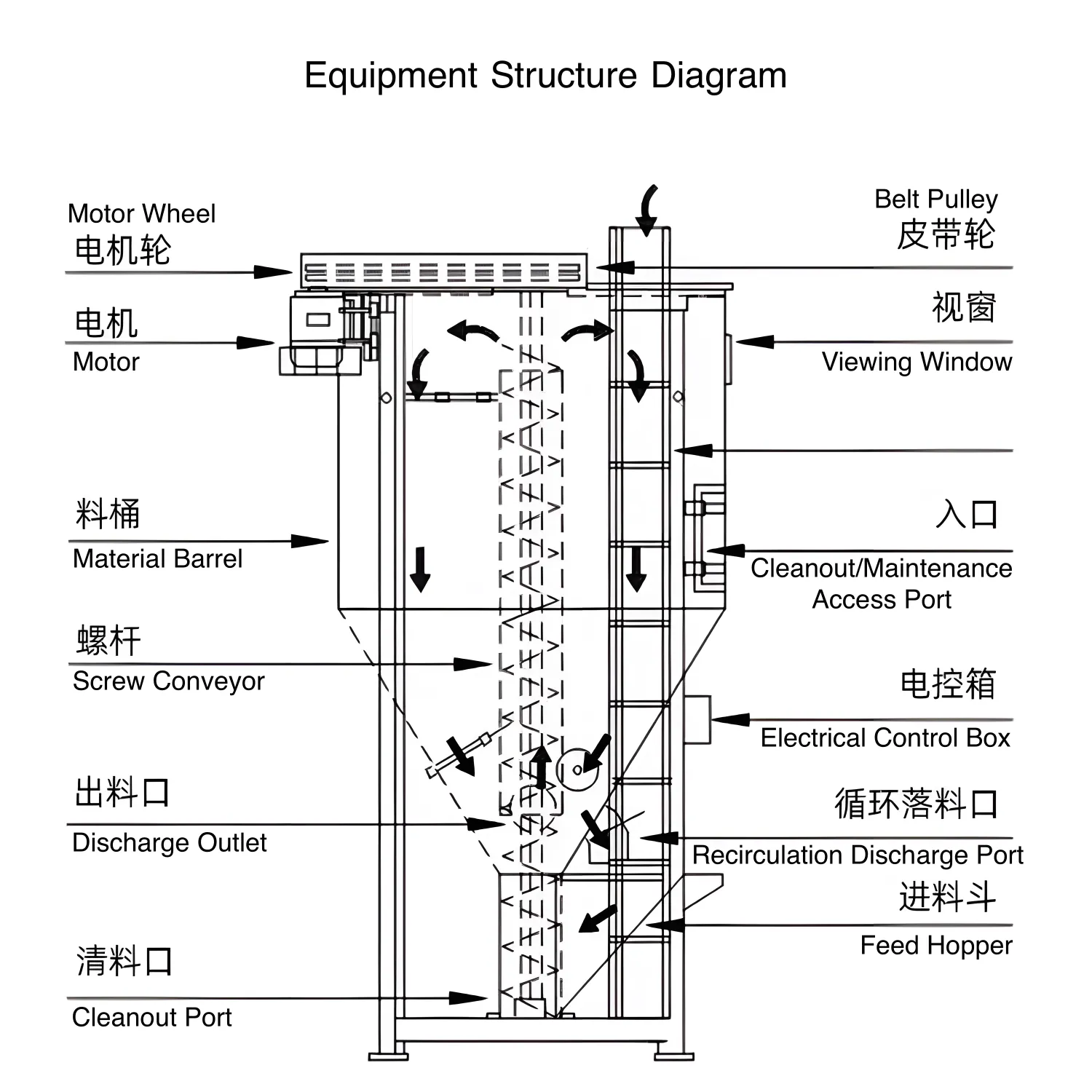

Como funciona: Mistura e secagem em um só processo

Um fluxo de trabalho simples de 3 etapas que mistura os materiais uniformemente, remove a umidade usando aquecimento e fluxo de ar, e os descarrega de forma limpa para o próximo processo.

- 1) Alimentação

Carregue pó, grânulos, pellets ou flocos na câmara vertical — a dosagem opcional auxilia no controle estável do lote.

- 2) Mistura

O sistema de mistura faz circular os materiais por todo o tanque para melhorar a uniformidade, ideal para misturar aditivos ou masterbatch.

- 3) Aquecimento, Secagem e Descarga

O aquecimento controlado com circulação de ar quente remove a umidade, e o fundo cônico facilita a descarga rápida e limpa para os equipamentos subsequentes.

Parâmetros técnicos

Especificações de referência para uma configuração padrão. Oferecemos suporte à personalização com base nos requisitos de material e do local.

| Nome | Especificação |

|---|---|

| Volume | 3000 L |

| Poder | 4 kW |

| Potência de aquecimento | 42 kW |

| Ventilador / Soprador | 2,2 kW |

| Espessura da Placa | 2,5 mm |

| Especificações do fuso | φ60 × 4 |

| Espessura da Lâmina | 3 mm |

| Diâmetro do parafuso | φ273 |

| Peso do equipamento | 700 kg |

| Dimensões | C1900 × L2300 × A3100 |

Formulários

Adequado para pós, grânulos e materiais leves em plásticos e na indústria em geral.

- Processamento de plásticos

Mistura e secagem de grânulos, flocos ou material reciclado de plástico para extrusão ou moldagem subsequente estável.

- Indústria química

Misturar e secar compostos químicos para obter uma mistura consistente e controle de umidade.

- Alimentos e bebidas

Misturar especiarias e pós, reduzindo a umidade, para obter melhor consistência e conservação.

- Produtos Farmacêuticos e Cosméticos

Mistura homogênea dos ingredientes e secagem controlada para atender aos requisitos do processo.

Benefícios

Uma única máquina que melhora a produtividade, a consistência e a eficiência operacional.

- Maior eficiência

Combina mistura e secagem em uma única unidade para reduzir o tempo de manuseio e simplificar seu fluxo de trabalho.

- %%

Melhora a homogeneidade e a estabilidade da umidade para um processamento subsequente confiável.

- Economia de energia

Um projeto otimizado de fluxo de ar e térmica ajuda a reduzir os custos operacionais gerais.

- Pé de Galinha Compacto

A orientação vertical economiza espaço no chão, mantendo o volume de trabalho.

Galeria de imagens

Manutenção e cuidados

Inspeções e limpezas de rotina ajudam a garantir um desempenho estável e uma longa vida útil.

- Verificações de rotina

Inspecione os componentes principais, os elementos de aquecimento e os dispositivos de segurança regularmente.

- Lubrificação

Mantenha os rolamentos e as peças móveis com lubrificação adequada para reduzir o desgaste e o ruído.

- Limpeza

Limpe a câmara após cada ciclo de produção para evitar o acúmulo de resíduos e a contaminação cruzada.

- Calibração

Verifique as configurações de temperatura e tempo para um desempenho de secagem consistente.

perguntas frequentes

É adequado para diversos pós e grânulos, incluindo grânulos/flocos de plástico, compostos químicos e certos pós alimentícios ou farmacêuticos. Informe-nos o tipo de material e o nível de umidade para confirmação.

Sim. O design de mistura vertical proporciona uma mistura homogênea. Podemos recomendar a velocidade/tempo de mistura com base na densidade aparente e na porcentagem de aditivos.

A seleção depende do tamanho do lote, da produção desejada, do teor de umidade e do espaço disponível para instalação. Compartilhe os detalhes do seu processo e proporemos uma configuração adequada.

Apoiamos os padrões comuns de energia industrial e podemos personalizar para a sua região. Forneça a sua tensão/frequência e o layout do local para confirmarmos a fiação e os equipamentos auxiliares.

Recomendamos a limpeza da câmara após a produção e a adoção de um plano de inspeção/lubrificação de rotina. Um guia de manutenção e uma lista de peças de reposição estão disponíveis.

Sim. Oferecemos opções de comissionamento remoto ou presencial, treinamento para operadores e suporte pós-venda com peças de reposição recomendadas para manutenção rápida.

Informe-se agora

Informe-nos o tipo de material, a capacidade desejada e o padrão de energia — nossa equipe recomendará a melhor solução.