Creëer hoogwaardige, Uniforme kunststofkorrels

Onze geavanceerde lijnen voor het pelletiseren van kunststof vormen de laatste stap in het omzetten van gerecycled plastic afval in een waardevolle, consistente en herbruikbare grondstof. We ontwikkelen complete systemen voor het compounderen, modificeren en pelletiseren van een breed scala aan polymeren.

Ontwerp uw pelletiseerlijn

Het kiezen van het juiste pelletiseersysteem

De ideale technologie hangt af van uw materiaaltype, outputvereisten en operationele voorkeuren. Wij zijn gespecialiseerd in twee primaire, zeer efficiënte systemen.

Waterstrengpelletiseerlijn

Een klassieke, robuuste en kosteneffectieve methode, ideaal voor een breed scala aan polymeren, vooral die welke gevoelig zijn voor temperatuurveranderingen.

- Proces: Gesmolten plastic wordt geëxtrudeerd tot strengen, afgekoeld in een waterbad en vervolgens door een granulator tot pellets gesneden.

- Het beste voor: PET, polystyreen (PS) en sterk gevulde of versterkte materialen.

- Voordeel: Eenvoudige bediening, makkelijk schoon te maken en veelzijdig voor laboratoria of grootschalige productie.

Waterringpelletiseerlijn

Een meer geautomatiseerd en compact systeem dat pellets bij de matrijs snijdt, ideaal voor de productie van grote volumes polyolefinen.

- Proces: Messen draaien rond het matrijsoppervlak en snijden de pellets af. Deze worden onmiddellijk afgekoeld en door een circulerende waterring getransporteerd.

- Het beste voor: PE, PP en andere materialen met een lagere smeltviscositeit.

- Voordeel: Produceert uniforme, bolvormige pellets, heeft minder vloeroppervlak nodig en is sterk geautomatiseerd.

Bekijk ons systeem in actie

Bekijk een complete rondleiding door een van onze geavanceerde productielijnen voor kunststofpellets, van grondstof tot hoogwaardige pellets.

Ontworpen voor ultieme pelletkwaliteit

Elk onderdeel wordt zorgvuldig geselecteerd om de zuiverheid, consistentie en waarde van uw eindproduct te garanderen.

-

Continue smeltfiltratie

Automatische zeefwisselaars verwijderen verontreinigingen zonder de productie te onderbreken, waardoor een zuivere smeltstroom wordt gegarandeerd.

-

Efficiënte ontwatering

Een verticale centrifugaaldroger verwijdert snel het oppervlaktewater uit de pellets, zodat ze gereed zijn voor classificatie en opslag.

-

Pelletclassificatie

Een trilzeef classificeert pellets op grootte en verwijdert te grote of te kleine deeltjes, zodat een zeer uniform eindproduct ontstaat.

-

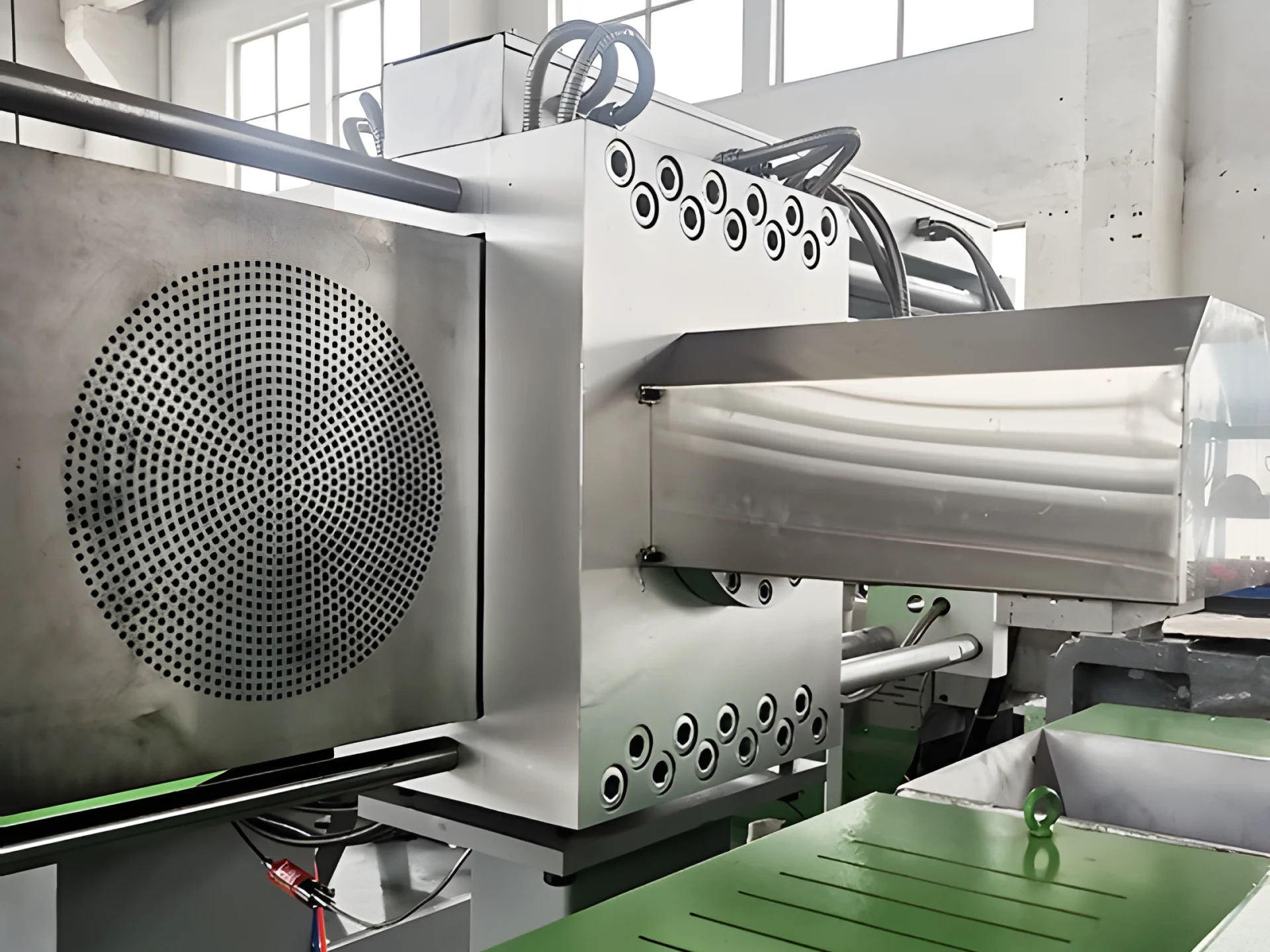

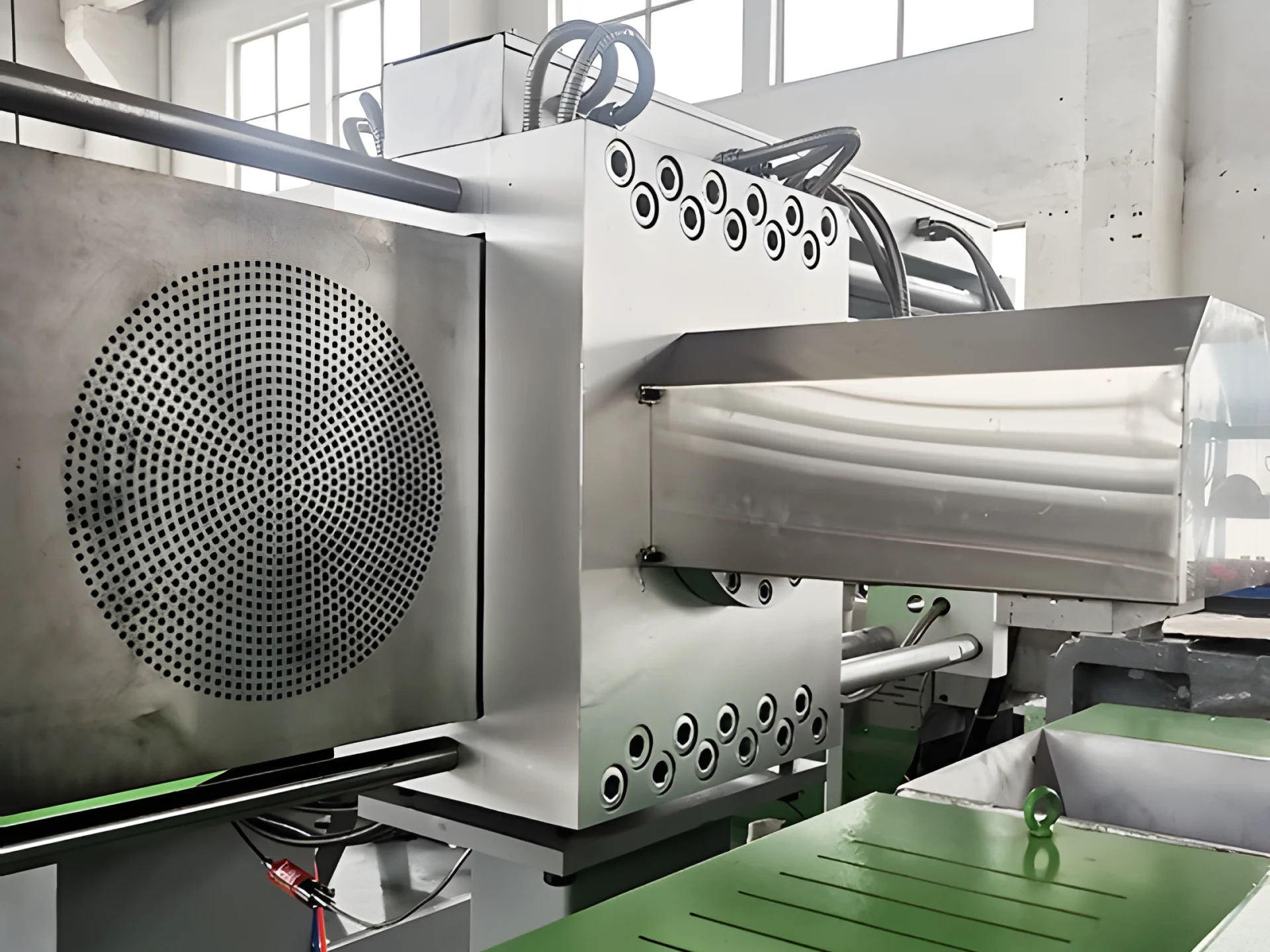

Precisie-dubbelschroefsextruder

Zorgt voor uitstekende menging en dispersie bij compounderingstoepassingen en garandeert de homogeniteit van additieven en vulstoffen.

Bereik eersteklas pelletkwaliteit

Onze systemen produceren schone, uniforme en goed verkoopbare pellets uit een breed scala aan invoermaterialen.

PE-pellets

Plastic foliekorrels

PVC- en harde plastickorrels

Bent u klaar om hoogwaardige plastic pellets te produceren?

Neem contact op met onze experts om uw specifieke materiaal en toepassing te bespreken. Wij ontwerpen een pelletiseer- of compoundeerlijn op maat die voldoet aan uw kwaliteits- en doorvoerdoelen.

Vraag een offerte aan voor een aangepast systeem