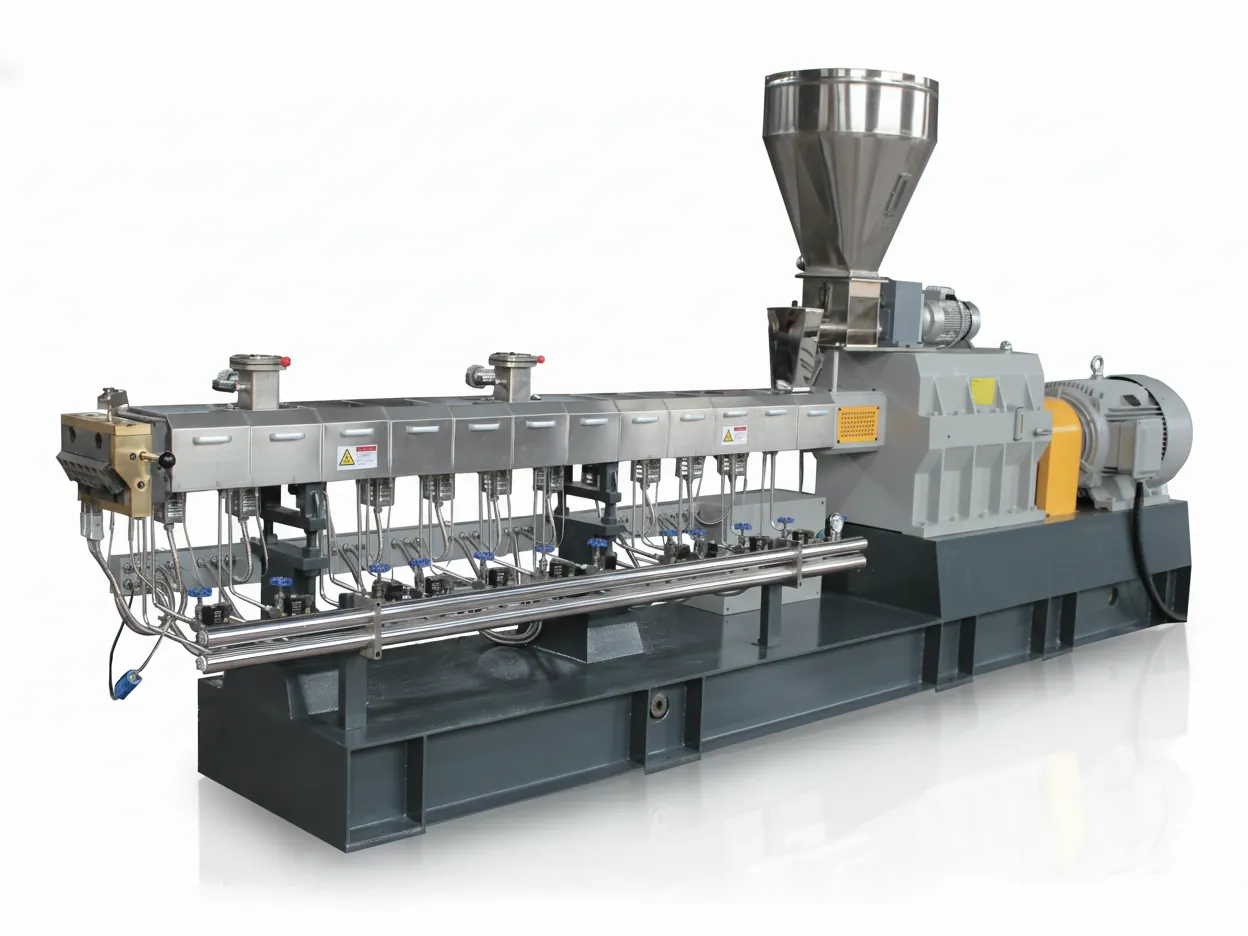

Twin Screw Compounding Extruder for Masterbatch & Fillers

Our twin-screw compounding line is a state-of-the-art solution engineered to conquer complex polymer processing challenges. It delivers unparalleled versatility and efficiency for plastics modification, masterbatch production, and compounding, helping you transform intricate formulations into high-value, homogeneous pellets.

Dapatkan Solusi & Penawaran KhususBagaimana itu bekerja

Our modular and precision-engineered screw elements break down the complex process into a series of highly efficient, controllable steps.

- 1. Pengisian Precisi

Sistem metering memastikan bahan mentah disiarkan dengan akurat dan konsisten.

- 2. Pemindahan & Pemanasan

Elemen screw membawa bahan melalui zona pemanasan untuk pemanasan yang cepat dan seragam.

- 3. Pemadat dan Penyebaran

Blok pemadat khusus menyediakan geseran yang kuat untuk penyebaran penambahan.

- 4. Homogenisasi & Pemudar

Ventus vakum menghilangkan kelembaban dan bahan volatil dengan efisiensi tinggi, meningkatkan kualitas karet.

- 5. Pemampatan & Ekstrusi

Tekanan yang stabil dibangun untuk mengekstrusi garis polimer yang leleh melalui kepala die.

- 6. Pemendangan & Penyusupan

Garis-garis disenduh dan dipotong oleh penyusup karet tinggi kecepatan menjadi karet berukuran yang konsisten.

Keunggulan Inti

- Desain Modul yang Sempurna

Customize everything from screw configurations to pelletizing methods. One machine adapts to multiple processes.

- Torque & Kecepatan yang Kuat

Multiple series available, from standard to ultra-high torque, powered by premium VFDs from brands like Siemens and ABB.

- Kontrol Otomatis yang Precisi

Equipped with OMRON or RKC intelligent temperature controllers with PID self-optimization for pinpoint accuracy.

- Komponen yang Tergantung dan Kualitas Dunia

Key components are sourced from trusted global brands like NSK, Schneider, and Siemens for long-term reliability.

Didesain untuk Keberlanjutan

Dibangun untuk Menahan Produksi yang Menantang

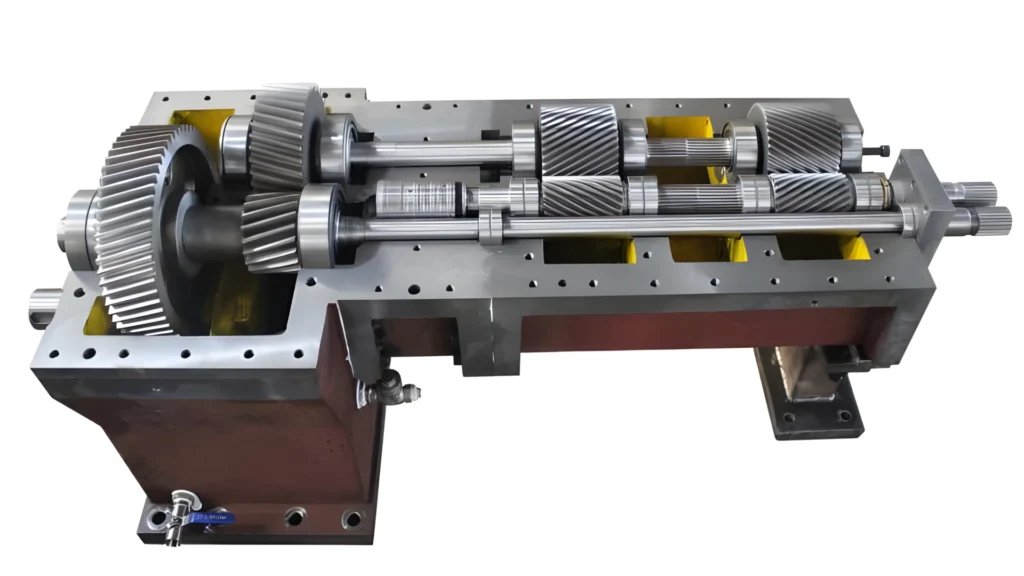

Our commitment to reliability is evident in every component. The heart of the machine, a high-torque distribution gearbox, is built with a significant safety margin, precision-machined gears, and imported key bearings for unmatched stability.

The standard bi-metallic barrel, featuring a wear-resistant alloy liner, is engineered for high performance, ensuring your investment is protected for the long term.

Transformasi tantangan menjadi kesempatan

Conventional polymer processing is filled with obstacles. Our twin-screw line provides the direct solutions you need.

- Tantangan: Pemadatan dan kualitas yang tak konsisten

Solusi kami: Innovative, co-rotating, self-wiping screw elements guarantee exceptional mixing and dispersion for batch-to-batch consistency.

- Tantangan: Kinerja bahan yang buruk

Solusi kami: The modular screw design allows for rapid reconfiguration, making it easy to switch between diverse formulations and polymers.

Berbagai Macam Aplikasi

- Masterbatch Fungsi

- Alloy Polimer

- Plastik Biodegradable

- Plastik Berkompresi

- Kompound Kabel & TPE

- Modifikasi Plastik Terkumpul

- Bahan yang Sempit Panas

- Ekstrusi Reaktif

Spesifikasi teknis

| Model | Diameter Piring (mm) | Rasio L/D Maksimal | Kecepatan Maksimal (RPM) | Daya Motor (kW) | Output (kg/hr) |

|---|---|---|---|---|---|

| RTM52C | 51.4 | 68 | 600 | 90 | 250-350 |

| RTM65C | 62.4 | 68 | 600 | 160 | 400-600 |

| RTM75C | 71.4 | 68 | 600 | 250 | 700-1000 |

| RTM85C | 81.0 | 68 | 600 | 280 | 800-1200 |

| RTM95C | 93.0 | 68 | 600 | 450 | 1300-2000 |

| RTM120C | 116.0 | 68 | 500 | 550 | 1500-2200 |

| RTM135C | 133.0 | 68 | 500 | 1200 | 3500-5000 |

Yang Membedakan kami

| Fitur | Lini Penyusupan Ganda Canggih kami | Pemadat Tunggal Konvensional |

|---|---|---|

| Kinerja Pemadatan | Pemadatan dan penyebaran yang luar biasa | Pemadatan yang tak konsisten |

| Kekuatan Proses | Sangat tinggi melalui desain screw modul | Sangat rendah, penggunaan terbatas |

| Pembersih Diri | Sangat baik, untuk pergantian yang cepat | Pembersih yang buruk, pemenuhan yang lambat |

| Pemudar | Sangat baik; mendukung vakum berbagai tahap | Tidak efisien dan terbatas |

Apa Kata Klien Kami

“We installed the RTM75C for our glass-fiber reinforced nylon compounds. The modular screw allowed us to quickly optimize for different GF percentages. The consistency of our final product has been outstanding, helping us secure key contracts in the automotive sector.”

“We were impressed by the stability and automation of this machine. The time from startup to stable production is significantly shorter, and the PLC touchscreen is intuitive, which has lowered our operator training costs. It’s an investment that has clearly paid off.”

Pertanyaan yang Sering Diajukan

Our twin-screw line can process nearly all thermoplastics and their composites, including PE, PP, ABS, PC, PET, PA, PLA, TPE, and TPU, along with various fillers, reinforcements, and functional additives.

Absolutely. We provide comprehensive turnkey services. Our experienced engineers can manage on-site installation and commissioning and will provide systematic training for your operators and maintenance staff.

Simply fill out the form at the bottom of this page or contact our sales team directly. We will work with you to understand your specific application and provide a detailed quote for the optimal machine configuration.

Siap Menaikkan Kualitas Proses Polimer?

Contact our technical experts today. We will provide a tailored equipment solution and a detailed quote based on your specific formulations, throughput requirements, and budget.