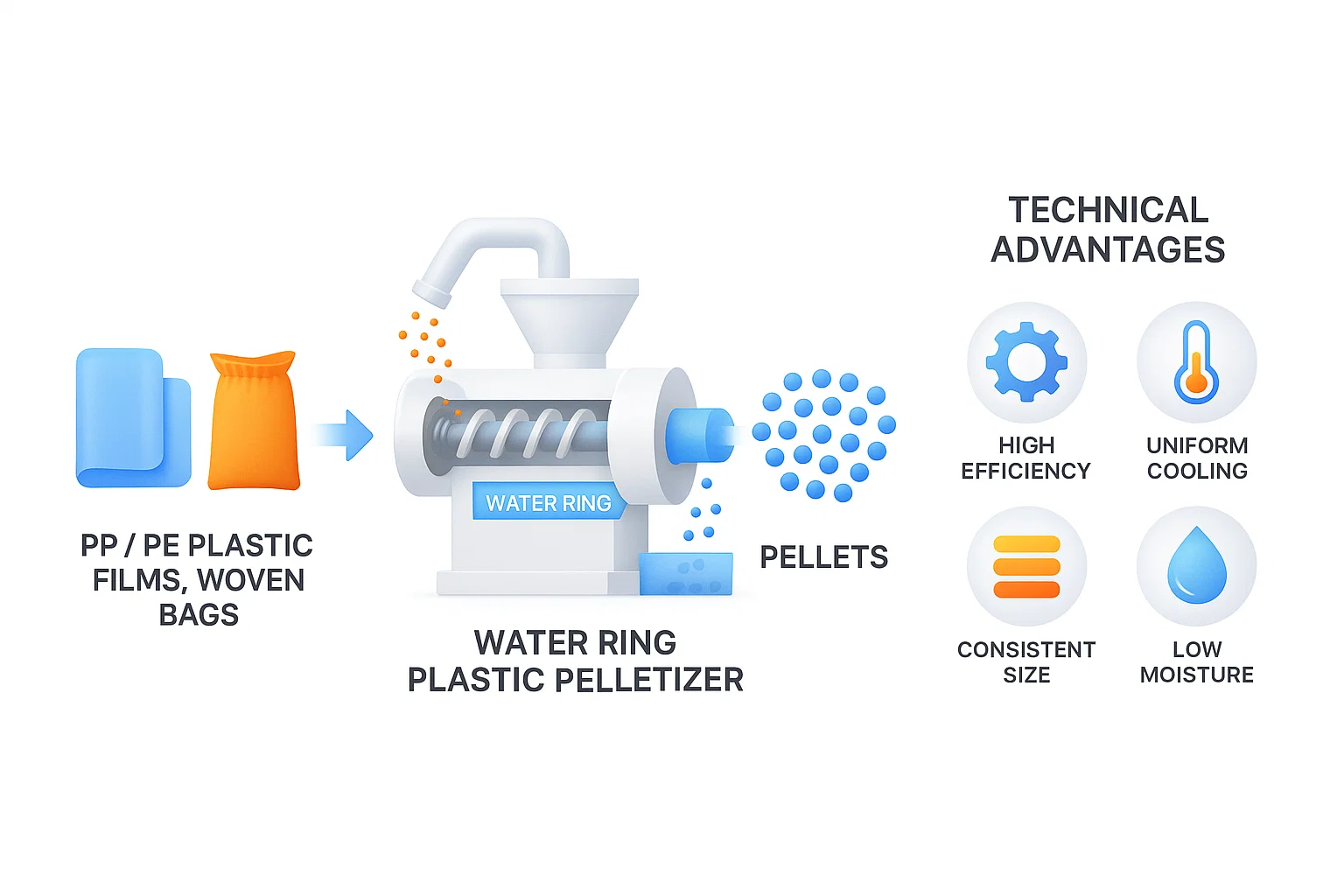

At Rumtoo, we specialise in delivering cutting-edge plastic recycling machinery designed to transform waste into valuable resources. Among our flagship solutions is the water ring plastic pelletizer, a highly efficient system that streamlines the recycling process for materials like PP (polypropylene) and PE (polyethylene) films and woven bags. This article explores the working principle of the water ring plastic pelletizer and its technical advantages, offering insights for industrial recycling equipment buyers and professionals seeking to optimise their operations.

What is a Water Ring Plastic Pelletizer?

UN water ring plastic pelletizer is an advanced recycling machine that converts plastic waste into uniform, high-quality pellets. These pellets serve as raw material for manufacturing new plastic products, supporting a circular economy. Unlike traditional pelletizing systems, the water ring pelletizer employs a unique hot die-face cutting method, combining efficiency, precision, and sustainability. It’s particularly effective for processing flexible plastics, such as films, raffia, and woven bags, making it a preferred choice for recycling plants worldwide.

Explore our water ring pelletizer for PP and PE plastic films and woven bags.

How Does a Water Ring Plastic Pelletizer Work?

The water ring plastic pelletizer operates through a streamlined, multi-stage process that ensures high-quality pellet production with minimal waste. Below is a step-by-step breakdown of its working principle, accompanied by a simplified workflow diagram for clarity.

Step-by-Step Working Principle

- Alimentation: Plastic waste, such as PP/PE films or woven bags, is fed into the machine via a belt conveyor or optional roll-hauling device. The feeding speed adjusts automatically based on the compactor’s capacity, ensuring consistent material flow and preventing overloading.

- Broyage et compactage: Rotatory blades within the compactor shred the plastic waste into smaller fragments. The frictional heat generated during this process preheats and compacts the material, reducing its volume and preparing it for extrusion. This step enhances feeding stability and removes residual moisture from washed plastics.

- Plasticisation and Degassing: The pre-compacted material enters a single-screw extruder, where it is gently melted. A vacuum exhaust system removes water vapour and volatile contaminants, improving pellet quality. This is particularly crucial for printed or slightly contaminated plastics, ensuring the pellets are suitable for high-quality applications like film blowing or pipe extrusion.

- Filtration par fusion: The molten plastic passes through a dual-station plate screen changer for segmented filtration. This process removes impurities, reducing the frequency of filter changes and ensuring consistent pellet quality. Advanced filtration minimises downtime and enhances operational efficiency.

- Water Ring Pelletizing: The molten plastic is extruded through a die head, where rotating blades cut it into uniform pellets as it contacts a ring of cooling water. This hot die-face cutting method ensures precise pellet size and shape. The pellets are then rapidly cooled and transported to a dewatering system.

- Dewatering and Drying: An advanced dewatering vibration sieve and horizontal centrifugal dryer remove water from the pellets, delivering high-performance, dry pellets ready for storage or immediate use in production lines.

Workflow Diagram

Below is a simplified diagram illustrating the workflow of a water ring plastic pelletizer:

[Plastic Waste] → [Belt Conveyor] → [Compactor/Shredder] → [Single-Screw Extruder] → [Melt Filtration] → [Die-Face Cutting (Water Ring)] → [Dewatering & Drying] → [Uniform Pellets]This efficient, one-step process integrates crushing, compacting, plasticisation, and pelletizing, reducing energy consumption and operational complexity compared to traditional systems.

Technical Advantages of Water Ring Plastic Pelletizers

The water ring plastic pelletizer offers distinct advantages over other pelletizing systems, such as strand or underwater pelletizers. These benefits make it a top choice for industrial recycling professionals aiming to enhance productivity and sustainability.

1. High-Quality Pellet Production

The hot die-face cutting system produces uniform, oval-shaped pellets with excellent surface quality. This consistency is critical for downstream applications like film blowing, pipe extrusion, and injection moulding, where pellet size and shape directly impact product quality. The water ring cooling method ensures rapid solidification, minimising defects and enhancing pellet aesthetics.

2. Energy Efficiency

By integrating multiple processes (crushing, compacting, and pelletizing) into a single stage, the water ring pelletizer reduces energy consumption compared to traditional multi-machine setups. The compactor’s frictional heat preheats the material, lowering the energy required for melting. Additionally, advanced extruder designs, such as those with heat wave stabilisation, ensure uniform heat distribution, further optimising energy use.

3. Versatility in Material Processing

The water ring pelletizer excels at processing a wide range of plastics, including soft materials like PP/PE films, woven bags, raffia, and even densified materials. Its flexibility makes it ideal for both post-industrial and post-consumer recycling, accommodating varying levels of contamination and material types.

4. Reduced Maintenance and Downtime

The dual-station screen changer allows for rapid filter changes without halting production, minimising downtime. The robust screw design, often crafted from high-durability materials like 38CrMoAIA with nitriding treatment, extends the lifespan of critical components to over 10,000 tonnes of processed material, significantly reducing maintenance costs compared to conventional systems.

5. Automated and User-Friendly Operation

Automated feeding and compacting systems adjust to material density and volume, ensuring stable operation. Features like metal detectors and optional roll-hauling devices enhance safety and ease of use, reducing the need for manual intervention. This automation is particularly valuable for large-scale recycling plants aiming to maximise throughput.

6. Environmental Benefits

By converting plastic waste into reusable pellets, the water ring pelletizer supports a closed-loop recycling process, reducing landfill waste and the demand for virgin plastic. Its efficient design minimises emissions and energy use, aligning with global sustainability goals and helping manufacturers meet regulatory requirements, such as the EU’s mandate for 50% recyclable plastic packaging by 2030.

Performance Comparison Chart

To illustrate the advantages of water ring pelletizers, the following chart compares key metrics against strand and underwater pelletizers:

| Fonctionnalité | Water Ring Pelletizer | Strand Pelletizer | Underwater Pelletizer |

|---|---|---|---|

| Pellet Shape | Oval, uniform | Cylindrical | Near-spherical |

| Consommation d'énergie | Faible | Modéré | Haut |

| Material Versatility | High (films, bags, raffia) | Limited (high MFI plastics) | Moderate (TPE, elastomers) |

| Maintenance Downtime | Low (dual-station filter) | Modéré | Haut |

| Production Efficiency | Haut | Modéré | Haut |

This comparison highlights the water ring pelletizer’s balance of efficiency, versatility, and low maintenance, making it a cost-effective solution for recycling professionals.

Why Choose Rumtoo’s Water Ring Plastic Pelletizer?

At Rumtoo, our water ring plastic pelletizers are engineered for reliability, efficiency, and durability. Here’s why industrial buyers trust us:

- Personnalisation: We offer tailored solutions to meet specific material and capacity requirements, ensuring optimal performance for your recycling plant.

- Proven Expertise: With decades of experience, Rumtoo has delivered recycling solutions to over 50 countries, earning a reputation for quality and innovation.

- Assistance complète: From pre-sales consultation to after-sales service, our team provides project planning, technical training, and ongoing support to maximise your ROI.

- Sustainability Focus: Our machines are designed to support green initiatives, helping you reduce waste and comply with environmental regulations.

Learn more about our water ring pelletizer and request a custom quote.

Conclusion

Le water ring plastic pelletizer is a game-changer for industrial recycling, offering a highly efficient, versatile, and sustainable solution for processing plastic waste. Its innovative working principle—combining shredding, compacting, plasticisation, and pelletizing in a single stage—delivers uniform, high-quality pellets while minimising energy use and downtime. For recycling professionals and equipment buyers, Rumtoo’s water ring pelletizer provides a reliable, customisable solution backed by industry-leading expertise.

Ready to elevate your plastic recycling operations? Contact Rumtoo today to explore how our water ring plastic pelletizer can transform your waste into valuable resources. Visit our product page for more details or to request a personalized consultation.