Water treatment has always been a critical aspect of many industrial processes, especially in plastic recycling, where wastewater management plays an essential role in maintaining environmental sustainability. Among the various technologies employed for water treatment, Flottation à air dissous (DAF) stands out as one of the most effective solutions. In this article, we will explore the fundamentals of DAF and its role in water treatment, particularly in the context of plastic recycling.

What is DAF (Dissolved Air Flotation) in Water Treatment?

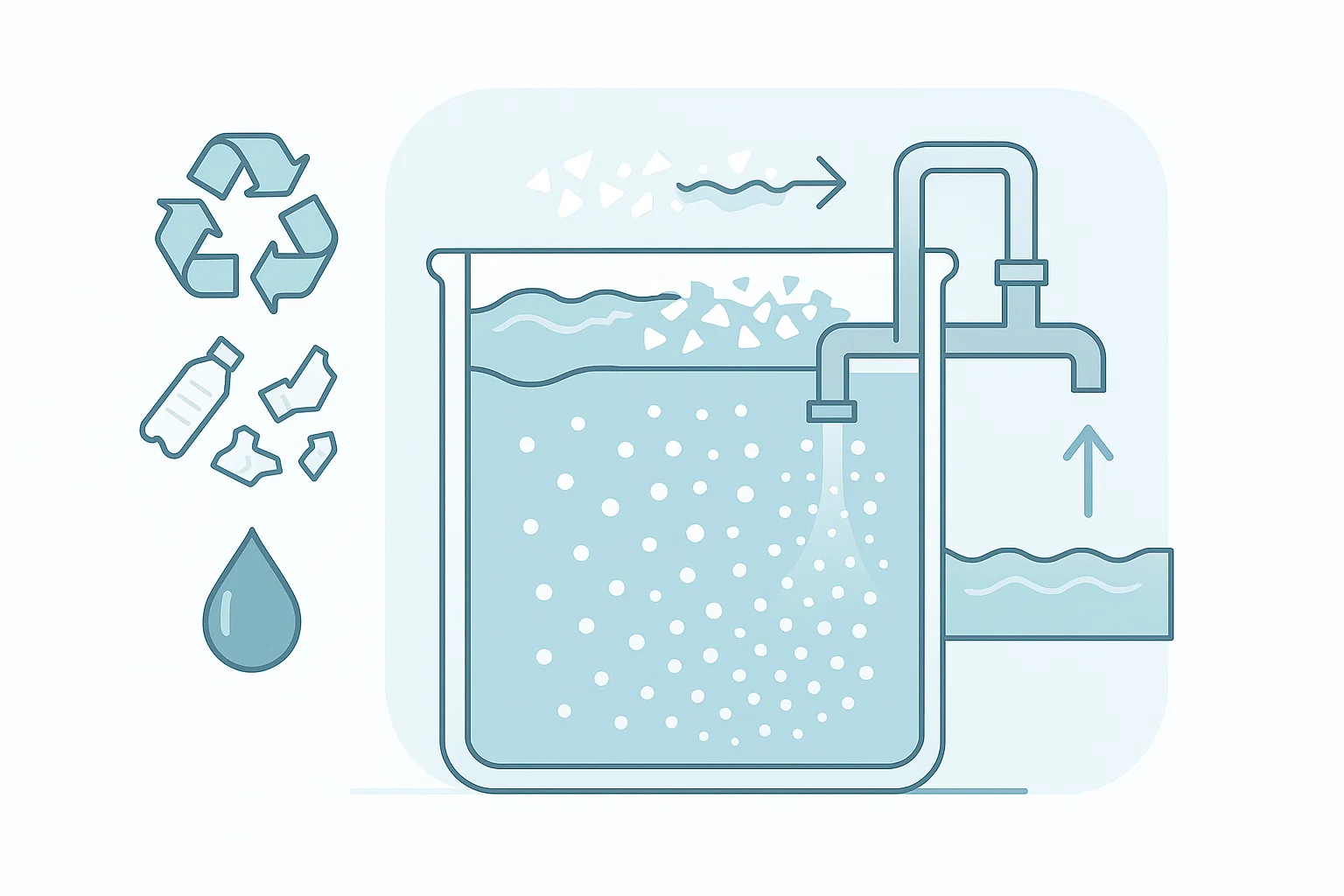

DAF, or Dissolved Air Flotation, is a water treatment process that removes suspended solids, oils, and other contaminants from water by utilizing microbubbles of air. These bubbles attach to the contaminants in the water, causing them to float to the surface where they can be easily removed. This technology is particularly effective for treating water with high levels of suspended solids and oily contaminants, making it widely used in industries like plastic recycling.

How Does DAF Work?

The DAF process involves the following key steps:

- Pre-Treatment: The wastewater is first conditioned with chemicals that promote the aggregation of suspended solids. Coagulants or flocculants are often used to bind smaller particles together.

- Saturation de l'air: Air is dissolved in water under pressure in a pressurized tank. The water is then released, and the air comes out of solution in the form of fine bubbles.

- Flottaison: The tiny air bubbles attach to the suspended contaminants, causing them to rise to the surface of the water.

- Écrémage: A mechanical skimmer removes the floating solids, while the treated water is collected for further use or discharge.

By using this efficient method, DAF helps separate contaminants in water and makes it possible for industries to treat and reuse water more effectively, reducing their environmental footprint.

Importance of DAF in Plastic Recycling

In plastic recycling, water is often used during various stages of the process, such as washing, cooling, and separation. As a result, large quantities of wastewater are generated, containing oils, plastics, and other pollutants that must be removed to ensure compliance with environmental regulations.

DAF plays a critical role in managing this wastewater. Here’s why DAF technology is particularly beneficial for plastic recycling:

- Efficient Removal of Contaminants: DAF systems efficiently remove suspended solids, oils, and even fine plastics that would otherwise pollute the environment.

- Water Reuse: After treatment, the water can be reused within the plant, reducing the need for fresh water and helping companies lower operational costs.

- Compliance with Regulations: Many industrial operations, including plastic recycling plants, are required to meet stringent environmental regulations regarding water quality. DAF helps businesses adhere to these regulations by ensuring that the treated water meets the necessary standards for discharge or reuse.

For more information on DAF systems and their applications in water treatment, visit Traitement efficace de l'eau par flottation à air dissous (DAF) pour le recyclage du plastique.

Key Benefits of DAF in Water Treatment

- Improved Water Quality: DAF technology is known for producing high-quality effluent, free from suspended solids, oils, and other pollutants. This makes it ideal for industries that require high standards of water quality for discharge or reuse.

- Rentable: While DAF systems require an initial investment, they offer long-term savings through water reuse, reduced wastewater treatment costs, and lower chemical consumption.

- Compact and Efficient: DAF units are often more compact than other treatment technologies, making them suitable for industries with limited space. They also operate efficiently, providing quick separation of contaminants.

- Impact environnemental: By improving the quality of treated water and reducing the need for new water sources, DAF technology contributes to environmental sustainability in industrial operations.

Comparing DAF with Other Water Treatment Technologies

While DAF is highly effective, it is important to understand how it compares with other water treatment technologies such as sedimentation and filtration.

| Fonctionnalité | DAF | Sédimentation | Filtration |

|---|---|---|---|

| Efficacité | High (removes fine particles) | Moderate (requires large space) | High (for specific contaminants) |

| Vitesse | Fast (minutes for separation) | Slow (hours for complete sedimentation) | Moderate (depends on filter type) |

| Besoins en espace | Compact and efficient | Requires large tanks | Varies (depending on filter type) |

| Coût | Moderate initial cost | Low initial cost, but high maintenance | High initial cost |

| Water Reuse | Excellent for water reuse | Limited water reuse capacity | Depends on filtration process |

As seen in the table above, DAF systems outperform traditional sedimentation in terms of speed and efficiency, especially in handling fine particles. While filtration is also effective, DAF remains an ideal choice for industries dealing with oily wastewater or complex waste streams.

Choosing the Right Water Treatment System for Your Industry

Selecting the right water treatment technology depends on the specific needs of your industrial operation. For plastic recycling, DAF is often the best choice due to its efficiency in handling oily, contaminated water and its ability to reuse water within the plant. However, it’s important to consult with water treatment professionals to assess your unique requirements, such as water volume, contaminant types, and regulatory compliance.

Conclusion

DAF technology has revolutionized the way industries treat wastewater, offering a powerful solution for removing contaminants and improving water quality. For plastic recycling plants, DAF provides the ideal balance of efficiency, cost-effectiveness, and environmental sustainability. By integrating DAF into your water treatment process, you can ensure a cleaner, greener future while maximizing your operational efficiency.

Investing in the right water treatment technology is essential for any plastic recycling facility looking to stay competitive in the industry while adhering to environmental regulations. If you are considering a DAF system for your operation, we invite you to learn more about the benefits of our efficient DAF solutions for plastic recycling ici.