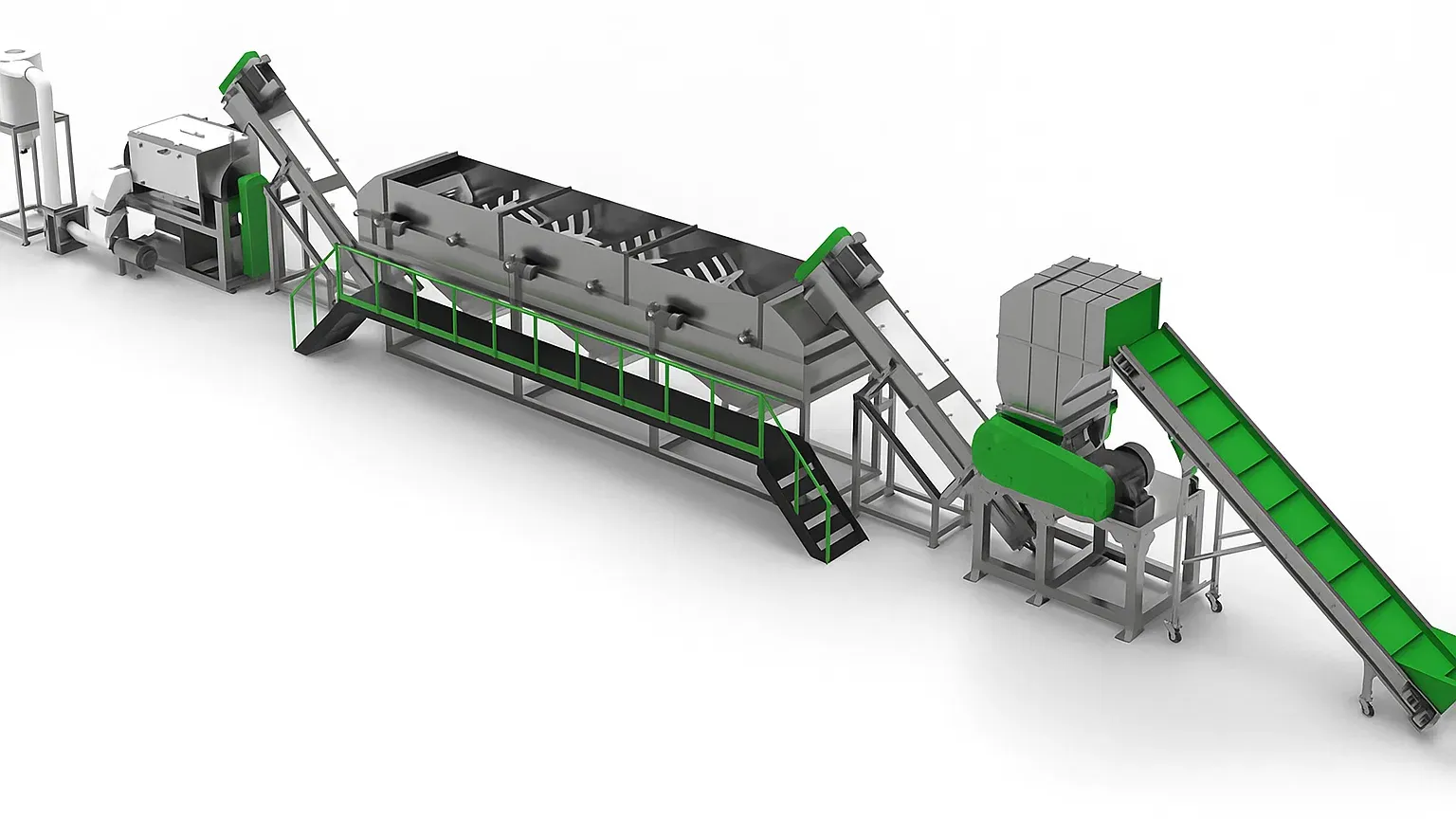

Plastic Film Washing Line for PE, PP Film & Woven Bags

Woven Bag & BOPP Film Washing Line for Raffia and Oriented PP Packaging Recycling Built specifically for PP woven bags (raffia) and oriented PP packaging films such as BOPP, CPP, and IPP. This turnkey washing line remo...