No mercado competitivo e ambientalmente consciente de hoje, os fabricantes de plástico estão cada vez mais descobrindo uma estratégia poderosa para aumentar seus lucros e, ao mesmo tempo, defender a sustentabilidade: a reciclagem interna de resíduos plásticos. Esse processo, também conhecido como reciclagem pós-industrial (PIR), envolve a recuperação e o reprocessamento de resíduos plásticos gerados durante a produção dentro da mesma instalação. Ao trazer a reciclagem para o seu próprio ambiente, as empresas estão transformando resíduos em um recurso valioso, aumentando a eficiência e abrindo caminho para um futuro mais verde.

O que exatamente é a reciclagem interna de resíduos plásticos?

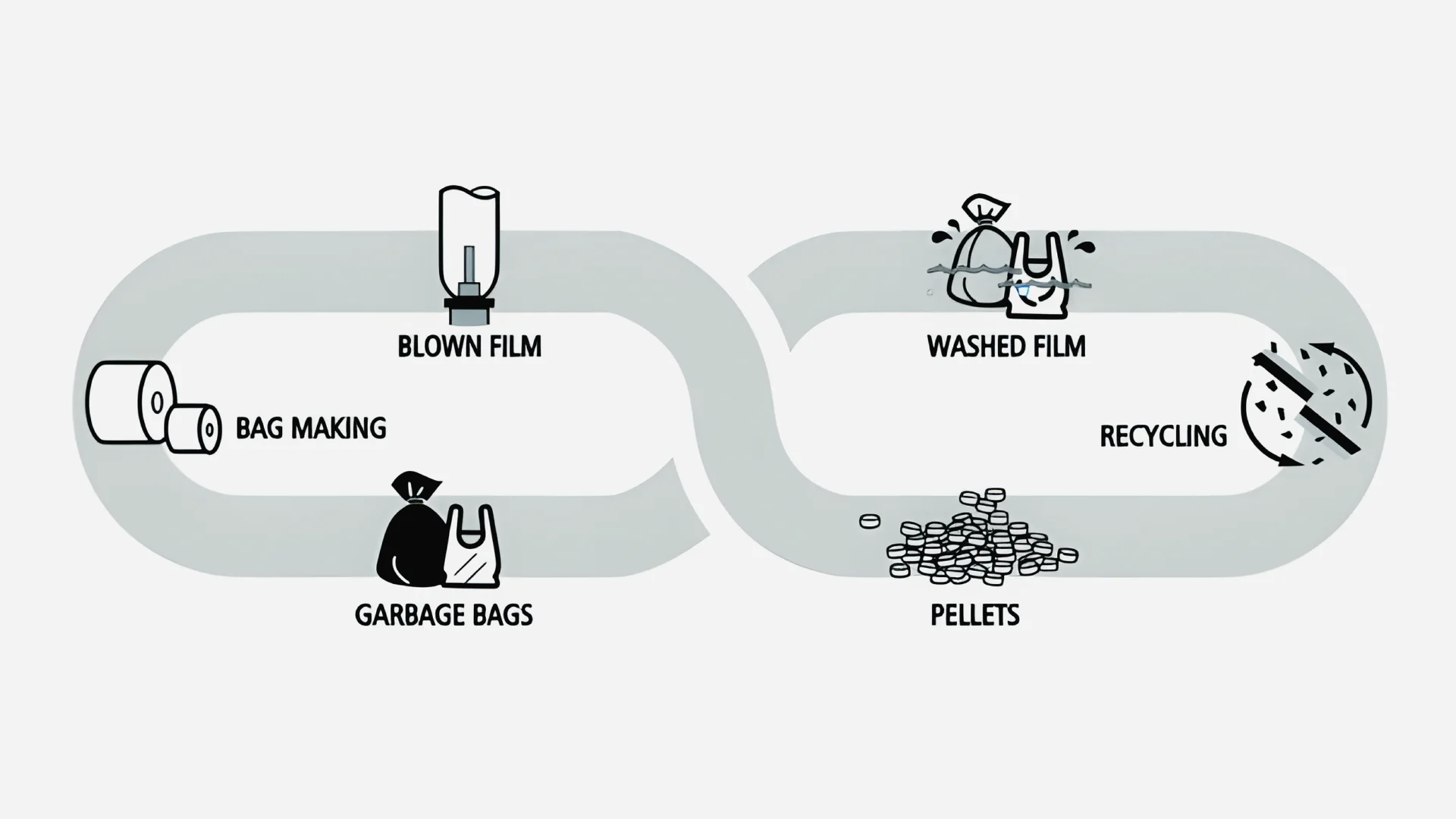

Em sua essência, a reciclagem interna é a recaptura e reutilização imediata de resíduos plásticos criados durante o processo de fabricação. Esse “resíduo limpo” inclui tudo, desde sobras e aparas até produtos defeituosos e materiais iniciais. Em vez de ser descartado ou vendido para recicladores terceirizados, esse plástico é processado no local e reintroduzido na linha de produção, criando um sistema de ciclo fechado que é eficiente e econômico.

Um tesouro de materiais recicláveis

Uma grande variedade de plásticos pós-industriais pode ganhar uma nova vida por meio da reciclagem interna. Alguns dos materiais mais comuns incluem:

- Filmes e sacos de PE (polietileno): Restos da produção de sacolas para camisetas, bem como restos de filmes de HDPE/LDPE impressos e não impressos, são os principais candidatos para reciclagem.

- Subprodutos da produção: Esta categoria abrange uma ampla gama de materiais, como fitas adesivas, tecidos provenientes da produção de ráfia e resíduos de processos de moldagem por sopro e injeção.

- Materiais defeituosos e excedentes: Em vez de se tornarem uma perda, produtos fora das especificações e materiais excedentes podem ser facilmente reprocessados em pellets de alta qualidade.

Por que todo fabricante de plástico deve considerar a reciclagem interna

A justificativa para a criação de um programa interno de reciclagem é convincente. Com a alta dos preços globais dos polímeros e a crescente ênfase na conservação de recursos, os fabricantes que adotam essa prática ganham uma vantagem competitiva significativa. A capacidade de incorporar mais conteúdo reciclado não apenas reduz os custos de produção como também reduz significativamente a pegada de carbono de uma empresa, alinhando-se às pressões regulatórias e às expectativas dos consumidores.

As vantagens tangíveis de levar a reciclagem para casa

1. Reduza custos e acelere prazos

Terceirizar a reciclagem para terceiros envolve uma série de obstáculos e despesas logísticas. Os fabricantes precisam separar, armazenar e transportar os resíduos e, em seguida, arcar com o próprio serviço de reciclagem, muitas vezes seguido pelo custo do transporte dos pellets reciclados de volta. A reciclagem interna contorna elegantemente essas complexidades. Ao eliminar as taxas de transporte e serviço, as empresas obtêm economias de custos imediatas. Além disso, a capacidade de reciclar sob demanda minimiza as necessidades de armazenamento e permite um cronograma de produção mais ágil e flexível.

2. Defender a Economia Circular

Ao transformar resíduos em matéria-prima valiosa, a reciclagem interna é um pilar fundamental da economia circular. Essa abordagem reduz a dependência de resinas virgens, conserva energia e reduz as emissões de gases de efeito estufa. Para fabricantes que atendem mercados com regulamentações rigorosas sobre conteúdo reciclado, como na Europa e nos Estados Unidos, produzir seu próprio material reciclado pós-industrial é o caminho mais eficiente e econômico para a conformidade.

3. Obtenha controle incomparável sobre a qualidade do material

A qualidade e a consistência dos materiais reciclados são fundamentais para a produção de produtos acabados de alta qualidade. Quando a reciclagem é realizada internamente, os fabricantes têm um profundo conhecimento do fluxo de resíduos. Eles conhecem a composição e as propriedades exatas do plástico reprocessado. Esse conhecimento permite a produção de pellets reutilizáveis 100% com características consistentes, garantindo que os produtos finais atendam a rigorosos padrões de qualidade. Esse nível de controle é simplesmente inatingível quando se depende de fornecedores externos de materiais reciclados.

4. Desbloqueie novas fontes de receita e aumente a lucratividade

Em uma era de custos flutuantes de matérias-primas, a resina plástica reciclada tornou-se uma mercadoria cada vez mais valiosa. Mesmo que um fabricante não utilize todos os pellets que produz, o excedente pode ser vendido no mercado aberto, transformando o que antes era um custo de descarte de resíduos em uma nova fonte de receita. A crescente demanda legal e industrial por conteúdo reciclado cria um mercado pronto para esses pellets pós-industriais de alta qualidade. Esses materiais são procurados para uma ampla gama de aplicações, incluindo moldagem por injeção, extrusão e moldagem por sopro, e são usados para criar tudo, desde bens de consumo, como garrafas de sabão em pó e brinquedos, até produtos industriais, como canos, móveis e materiais de construção.

Ao adotar a reciclagem interna de resíduos plásticos, os fabricantes podem se posicionar como líderes em um setor em rápida evolução, demonstrando um compromisso com a sustentabilidade que repercute tanto entre clientes quanto entre stakeholders, ao mesmo tempo em que fortalecem seu desempenho financeiro. É uma decisão estratégica que não é apenas boa para o planeta, mas também para os negócios.