In today’s competitive and environmentally-conscious market, plastic manufacturers are increasingly discovering a powerful strategy to boost their bottom line while championing sustainability: in-house plastic waste recycling. This process, also known as post-industrial recycling (PIR), involves reclaiming and reprocessing plastic scrap generated during production right within the same facility. By bringing recycling under their own roof, companies are transforming waste into a valuable resource, driving efficiency, and paving the way for a greener future.

What Exactly is In-House Plastic Waste Recycling?

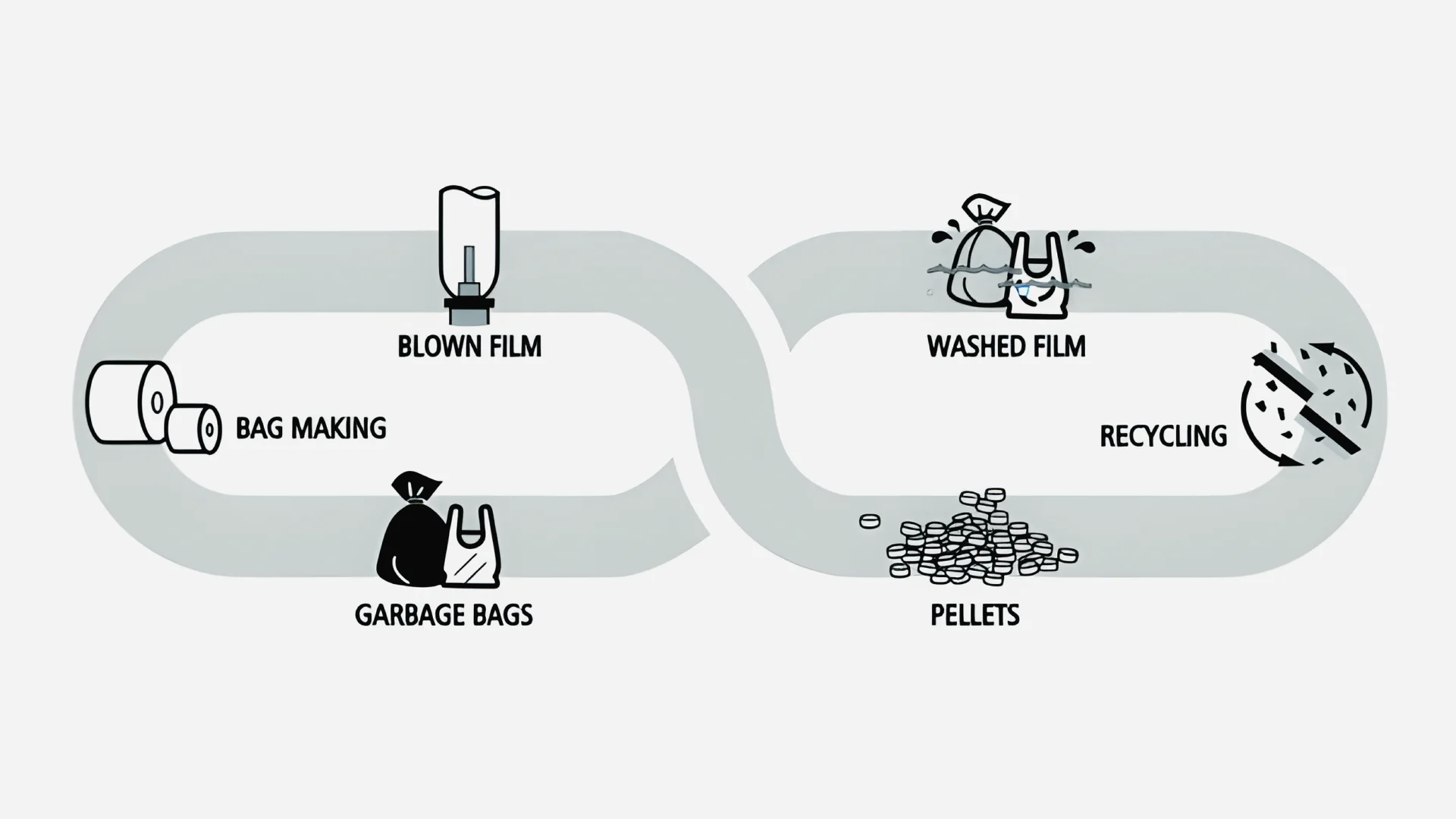

At its core, in-house recycling is the immediate recapture and reuse of plastic waste created during the manufacturing process. This “clean waste” includes everything from off-cuts and trimmings to defective products and start-up materials. Instead of being discarded or sold to third-party recyclers, this plastic is processed on-site and reintroduced into the production line, creating a closed-loop system that is both efficient and economical.

A Treasure Trove of Recyclable Materials

A wide variety of post-industrial plastics can be given a new life through in-house recycling. Some of the most common materials include:

- PE (Polyethylene) Film and Bags: Scraps from T-shirt bag production, as well as printed and unprinted HDPE/LDPE film remnants, are prime candidates for recycling.

- Production Byproducts: This category encompasses a broad range of materials such as draw tapes, woven fabrics from raffia production, and waste from blow molding and injection molding processes.

- Defective and Surplus Materials: Instead of becoming a loss, off-spec products and excess materials can be seamlessly reprocessed into high-quality pellets.

Why Every Plastic Manufacturer Should Consider In-House Recycling

The case for establishing an in-house recycling program is compelling. With global polymer prices on the rise and a growing emphasis on resource conservation, manufacturers who embrace this practice gain a significant competitive edge. The ability to incorporate more recycled content not only slashes production costs but also demonstrably reduces a company’s carbon footprint, aligning with both regulatory pressures and consumer expectations.

The Tangible Advantages of Bringing Recycling Home

1. Slash Costs and Accelerate Timelines

Outsourcing recycling to a third party involves a cascade of logistical hurdles and expenses. Manufacturers must sort, store, and transport waste, and then pay for the recycling service itself, often followed by the cost of transporting the recycled pellets back. In-house recycling elegantly sidesteps these complexities. By eliminating transportation and service fees, companies realize immediate cost savings. Furthermore, the ability to recycle on-demand minimizes storage needs and allows for a more streamlined and flexible production schedule.

2. Champion the Circular Economy

By transforming waste into a valuable raw material, in-house recycling is a cornerstone of the circular economy. This approach reduces the reliance on virgin resins, conserves energy, and lowers greenhouse gas emissions. For manufacturers serving markets with stringent regulations on recycled content, such as in Europe and the United States, producing their own post-industrial recycled material is the most efficient and cost-effective path to compliance.

3. Gain Unparalleled Control Over Material Quality

The quality and consistency of recycled materials are paramount for producing high-caliber finished products. When recycling is handled in-house, manufacturers have an intimate understanding of the waste stream. They know the exact composition and properties of the plastic being reprocessed. This knowledge allows for the production of 100% reusable pellets with consistent characteristics, ensuring that the final products meet strict quality standards. This level of control is simply unattainable when relying on external suppliers of recycled materials.

4. Unlock New Revenue Streams and Boost Profitability

In an era of fluctuating raw material costs, recycled plastic resin has become an increasingly valuable commodity. Even if a manufacturer doesn’t use all of the pellets they produce, the surplus can be sold on the open market, turning what was once a waste disposal cost into a new source of revenue. The growing legal and industrial demand for recycled content creates a ready market for these high-quality, post-industrial pellets. These materials are sought after for a wide range of applications, including injection molding, extrusion, and blow molding, and are used to create everything from consumer goods like laundry detergent bottles and toys to industrial products like pipes, furniture, and construction materials.

By embracing in-house plastic waste recycling, manufacturers can position themselves as leaders in a rapidly evolving industry, demonstrating a commitment to sustainability that resonates with customers and stakeholders alike, all while strengthening their financial performance. It’s a strategic decision that is not just good for the planet, but great for business.