Industrial Plastic Recycling Machine Solutions

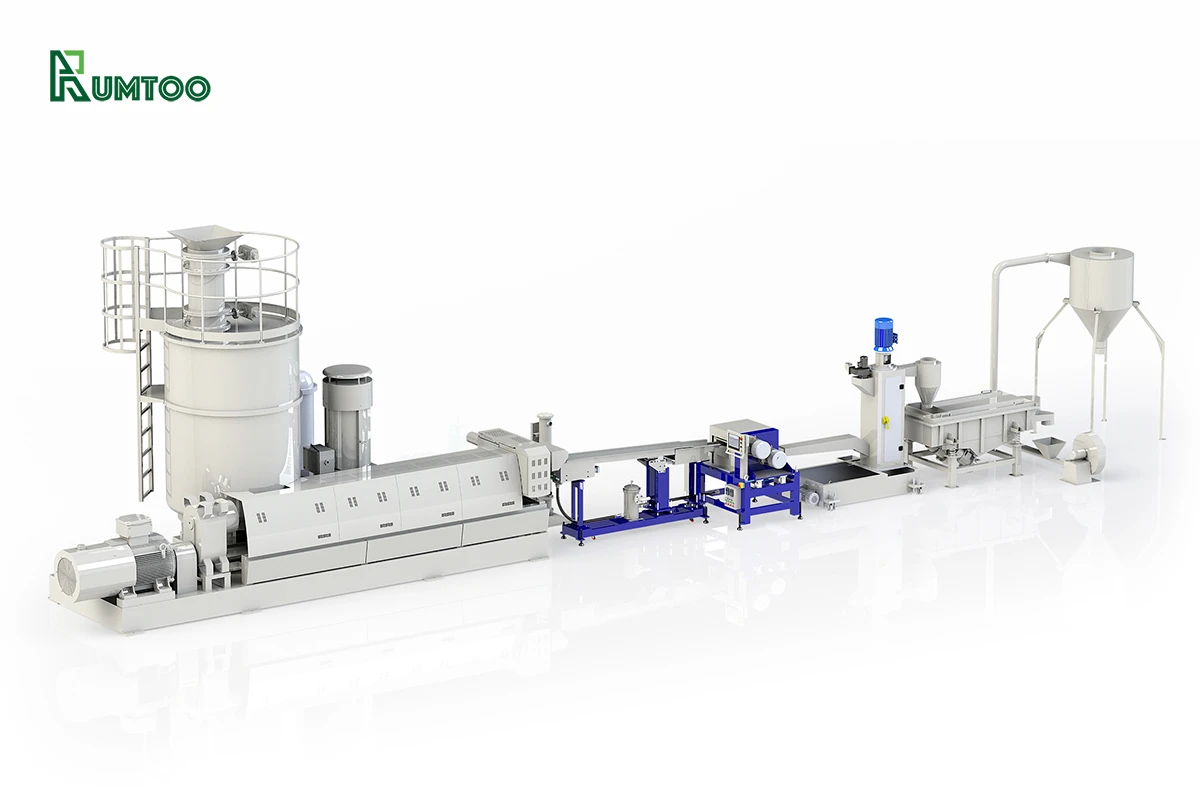

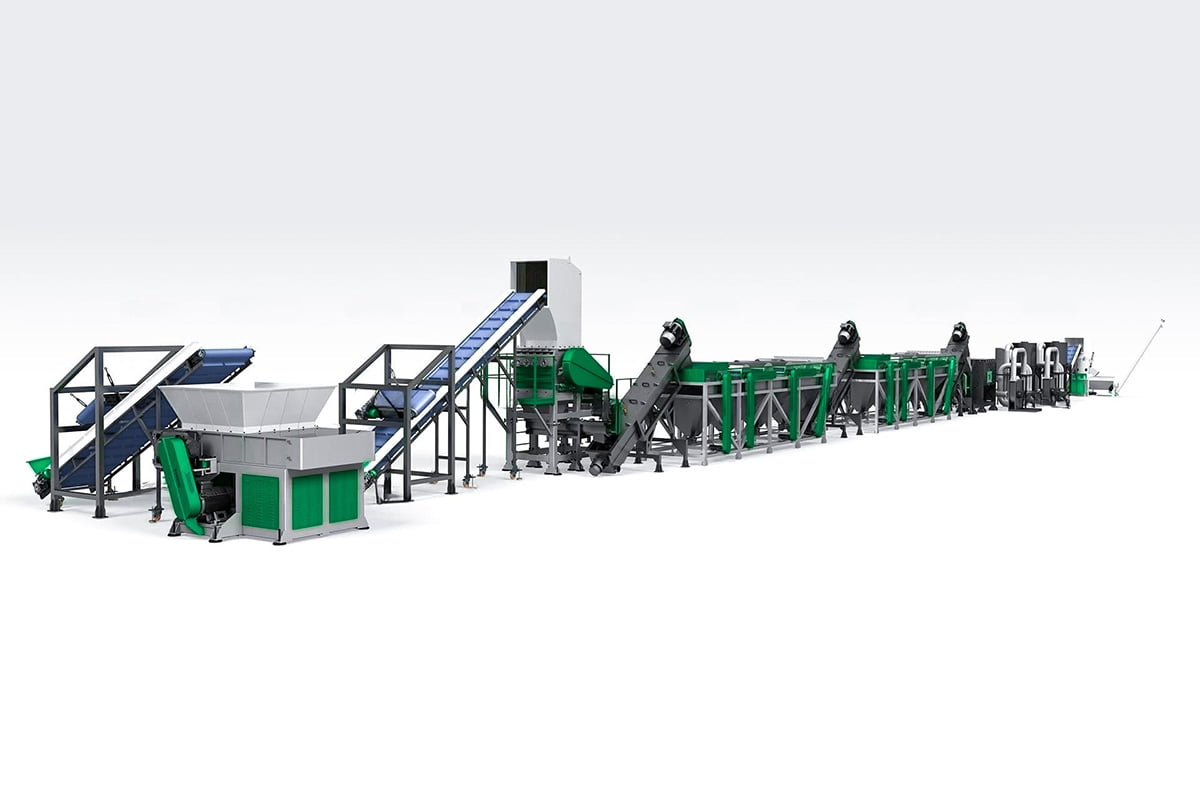

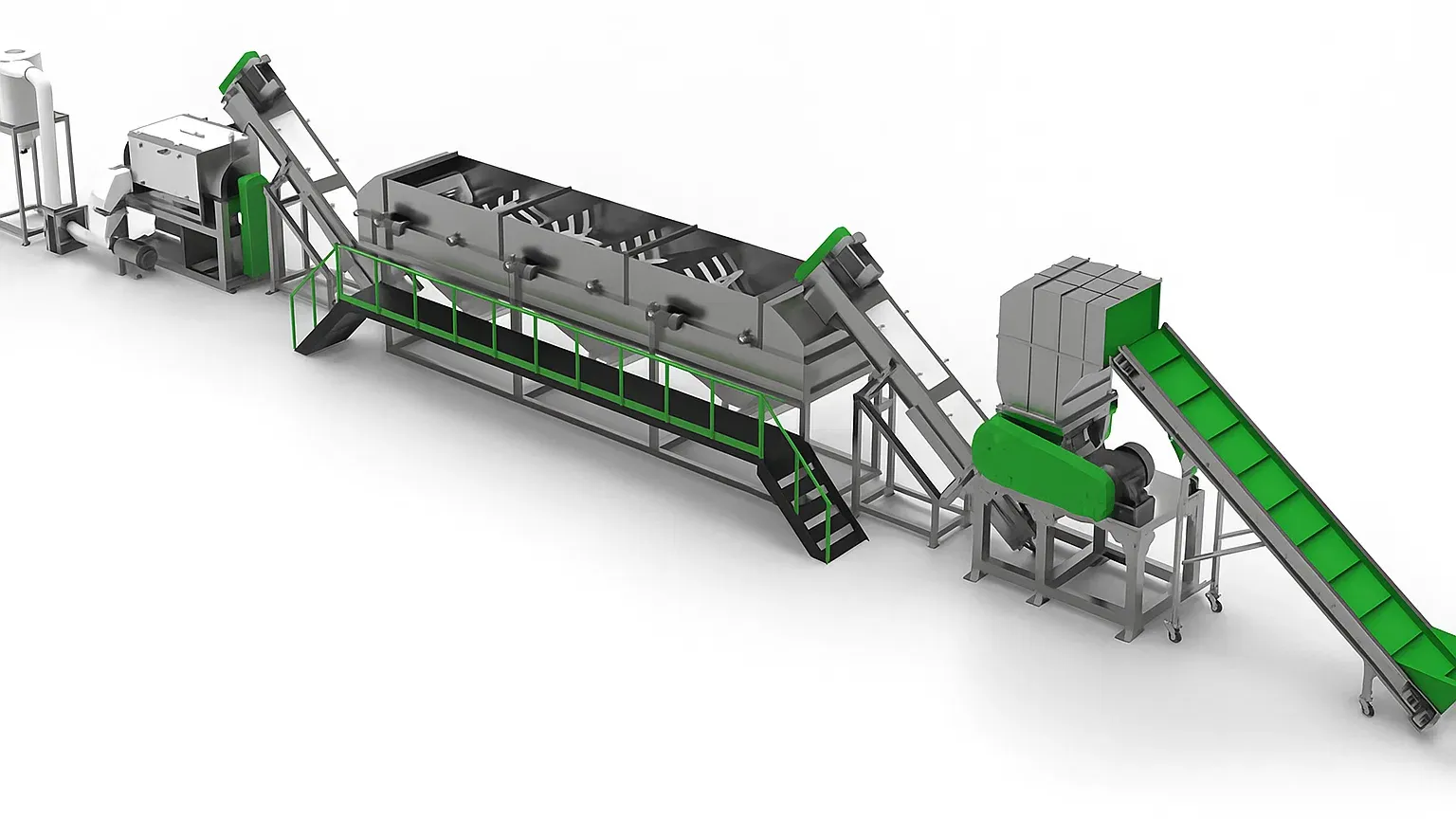

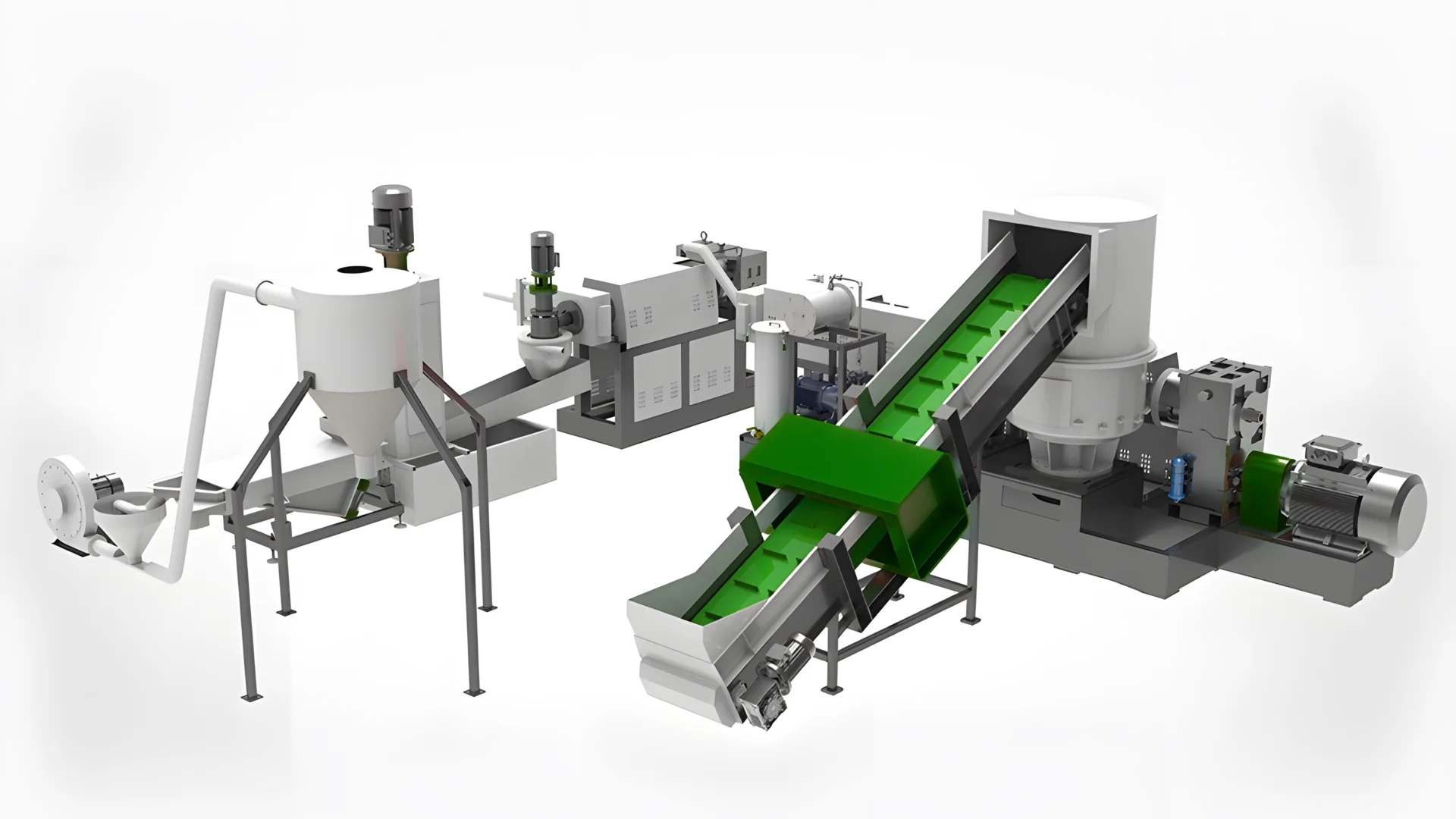

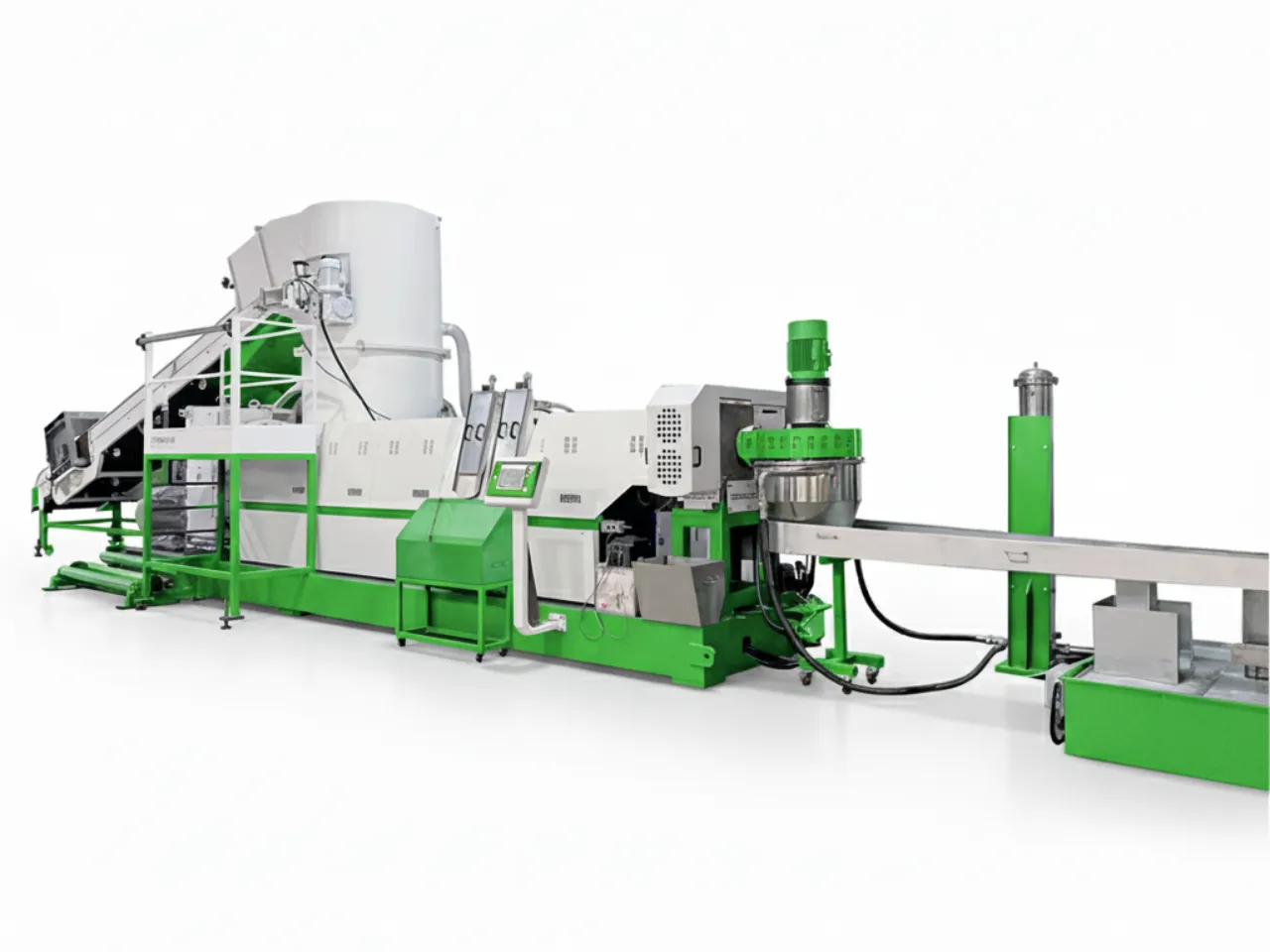

Discover our industrial-grade plastic recycling machine systems engineered into complete turnkey lines. We deliver shredding, washing, drying, and pelletizing solutions that convert waste plastics into high-value, reusable pellets.

Get a Custom QuoteBrowse Machine Categories

Popular Recycling Solutions

Why Choose Our Recycling Machines?

High Throughput & Efficiency

Our machines are engineered for maximum processing capacity, ensuring a smooth, continuous workflow that boosts your productivity and reduces operational costs.

Energy-Efficient Systems

Designed to minimize power and water consumption, our eco-friendly systems lower your operational costs and significantly reduce your carbon footprint.

Superior Output Quality

Advanced multi-stage purification, filtration, and degassing processes result in high-purity, market-ready pellets suitable for premium applications.

Intelligent PLC Control

User-friendly touch screen interfaces provide one-touch control of the entire line, simplifying operation and real-time performance monitoring.

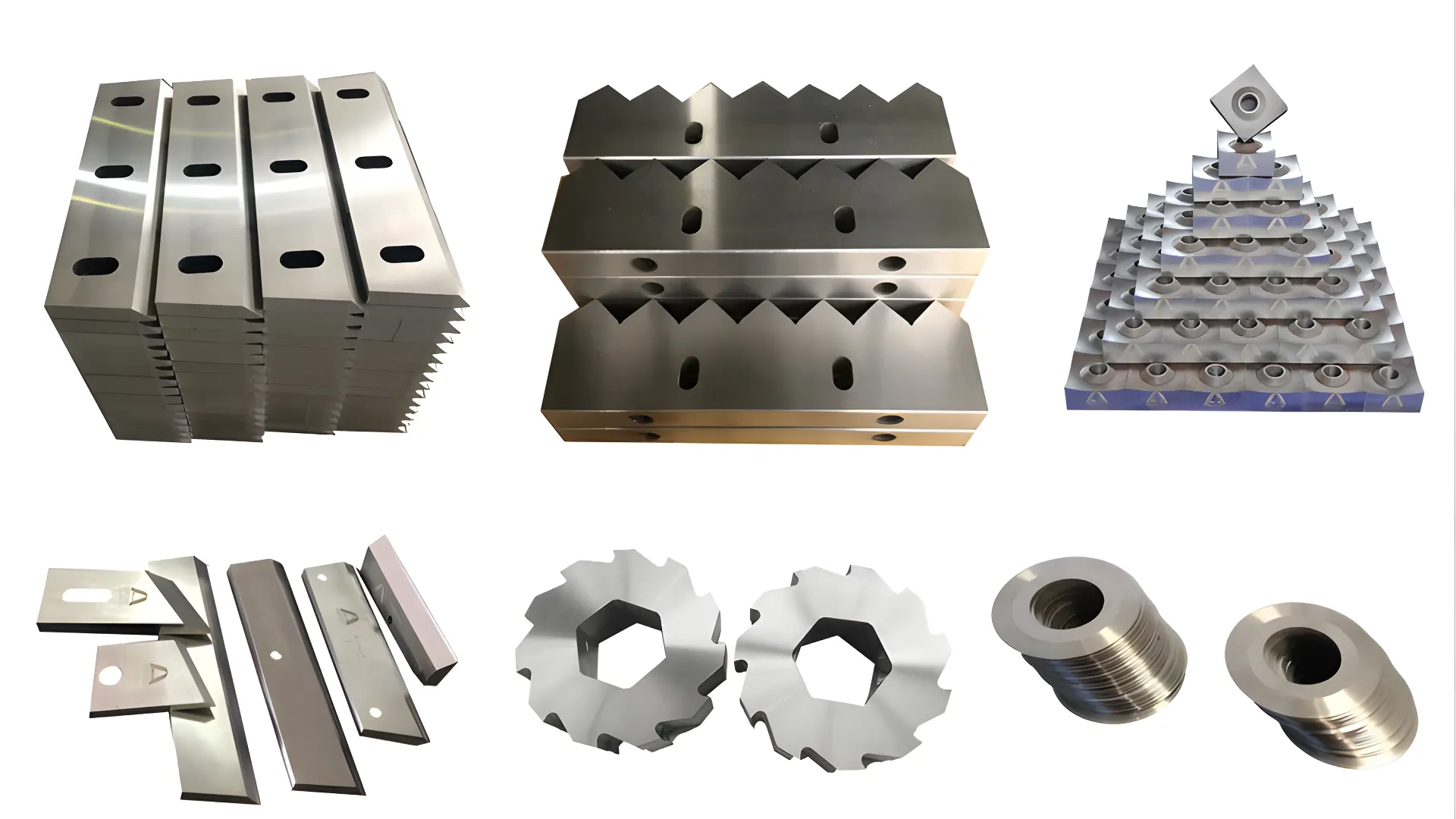

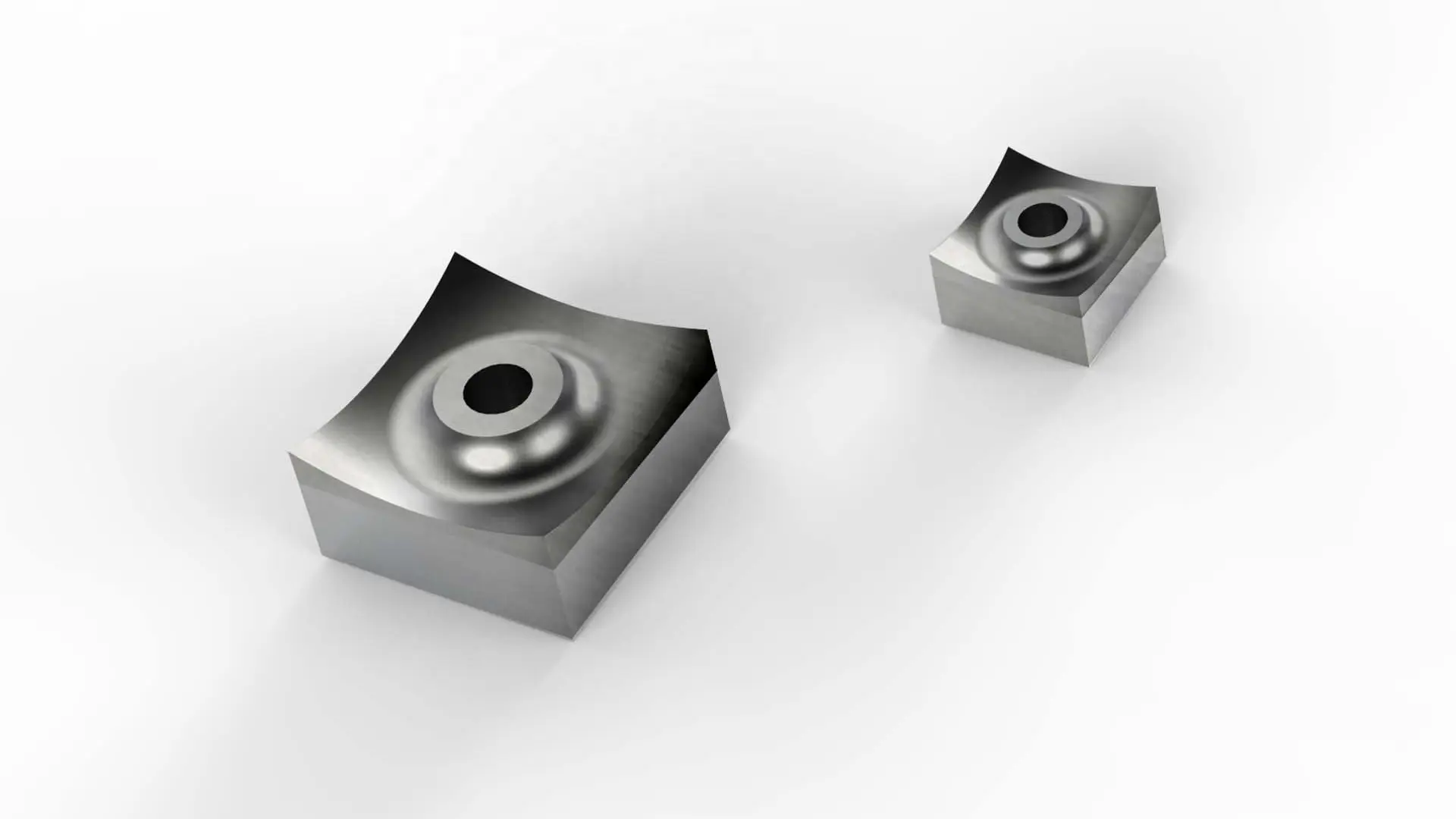

Robust & Durable Construction

Built with high-grade, wear-resistant alloys and heavy-duty components designed to withstand 24/7 industrial operation and ensure long-term reliability.

Global Support & Service

Our expert team provides comprehensive support including installation, commissioning, staff training, and reliable spare parts supply worldwide.

Our 6-Stage Plastic Recycling Process

Stage 1: Sorting & Separation

Raw plastic waste is sorted to remove contaminants. Advanced systems separate plastics by type and color to ensure the highest purity for downstream processing.

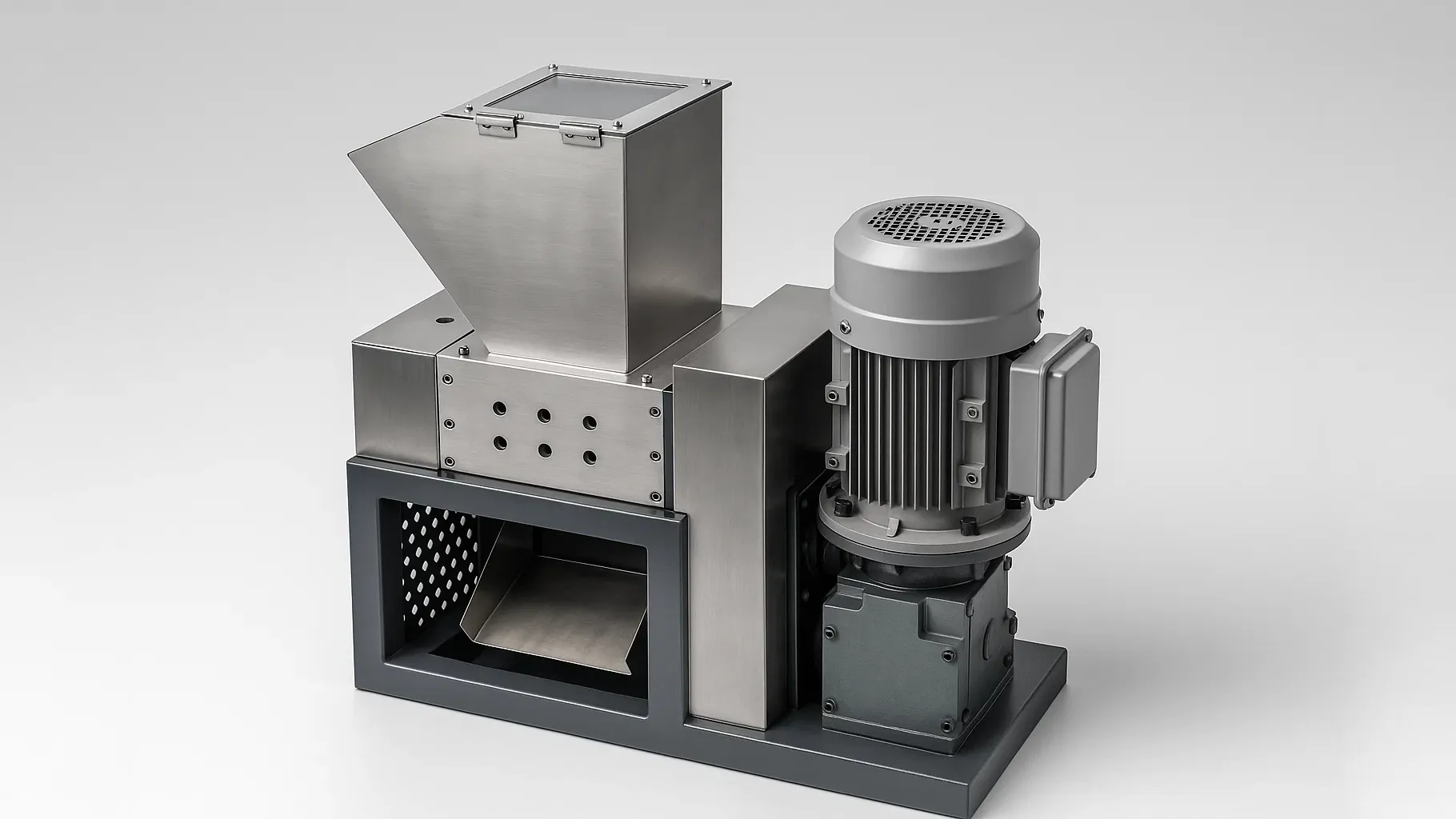

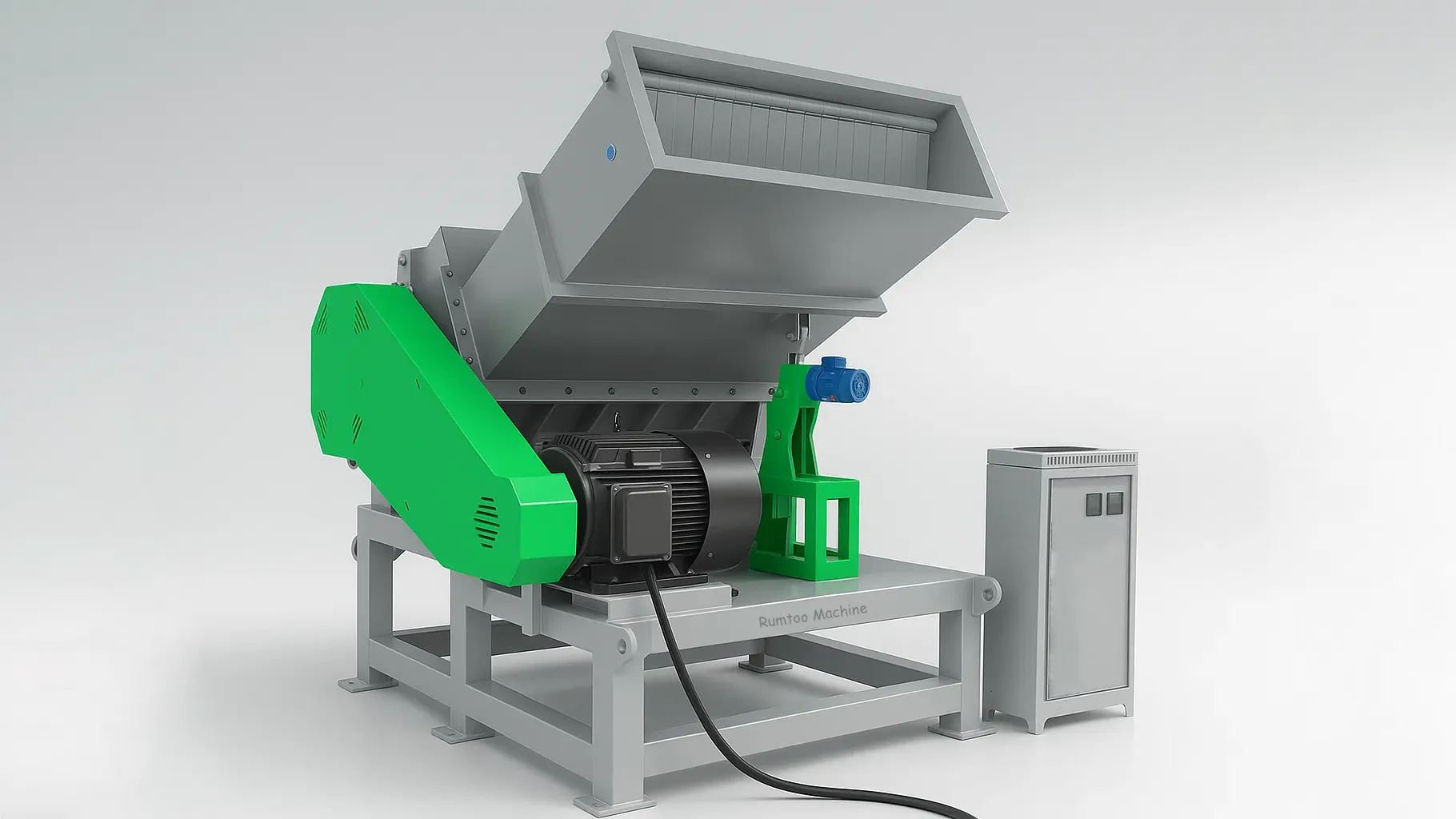

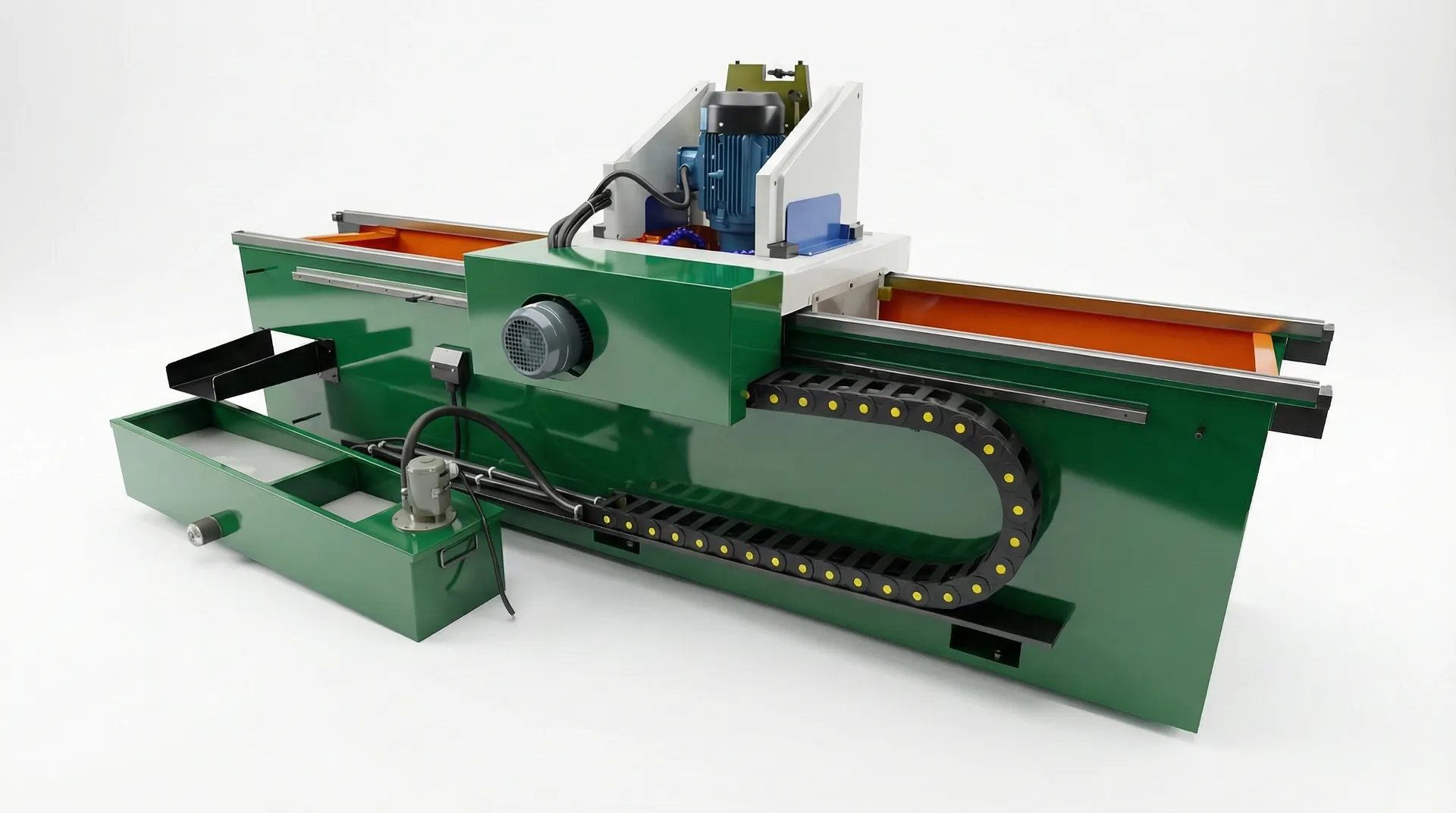

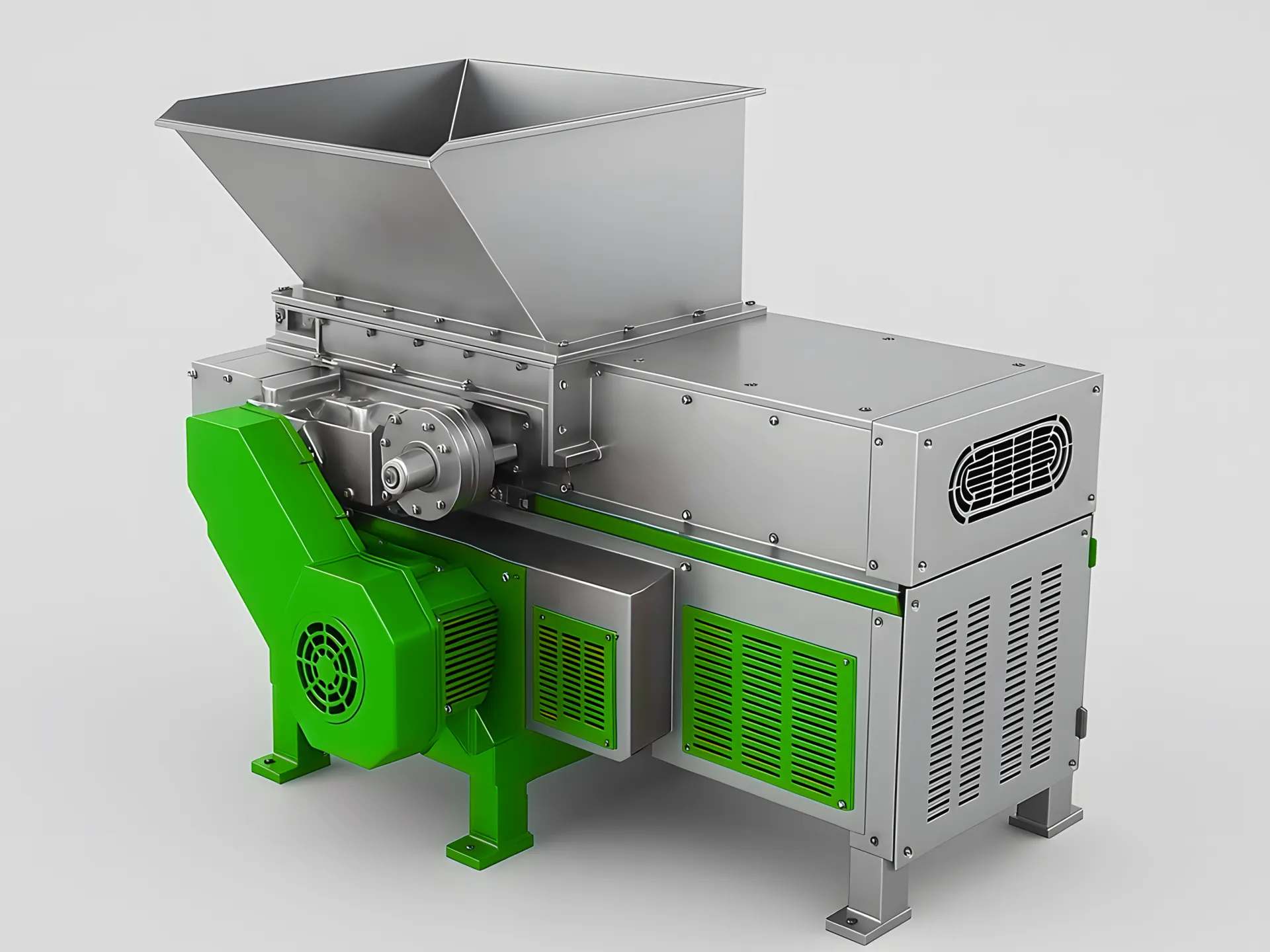

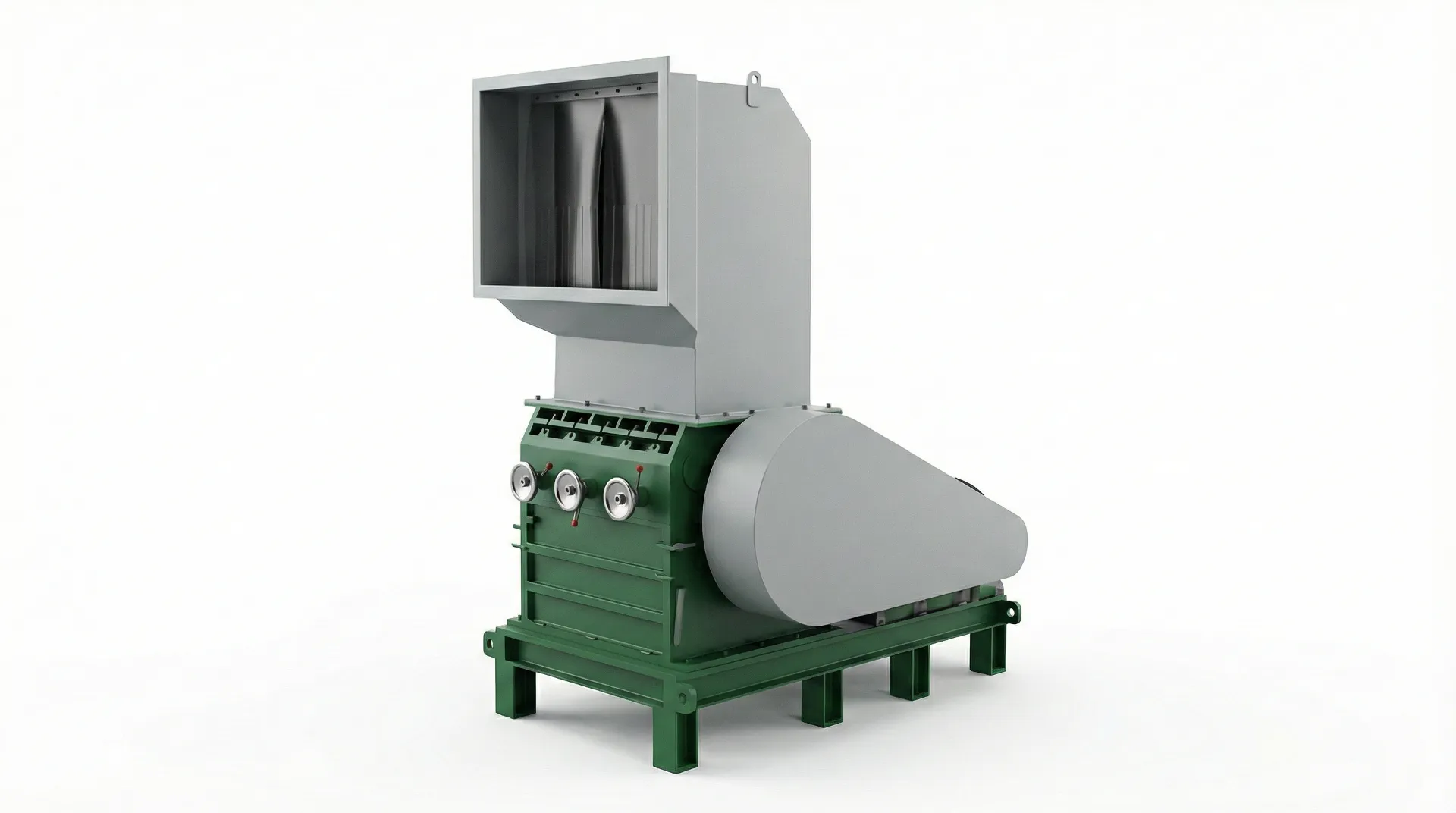

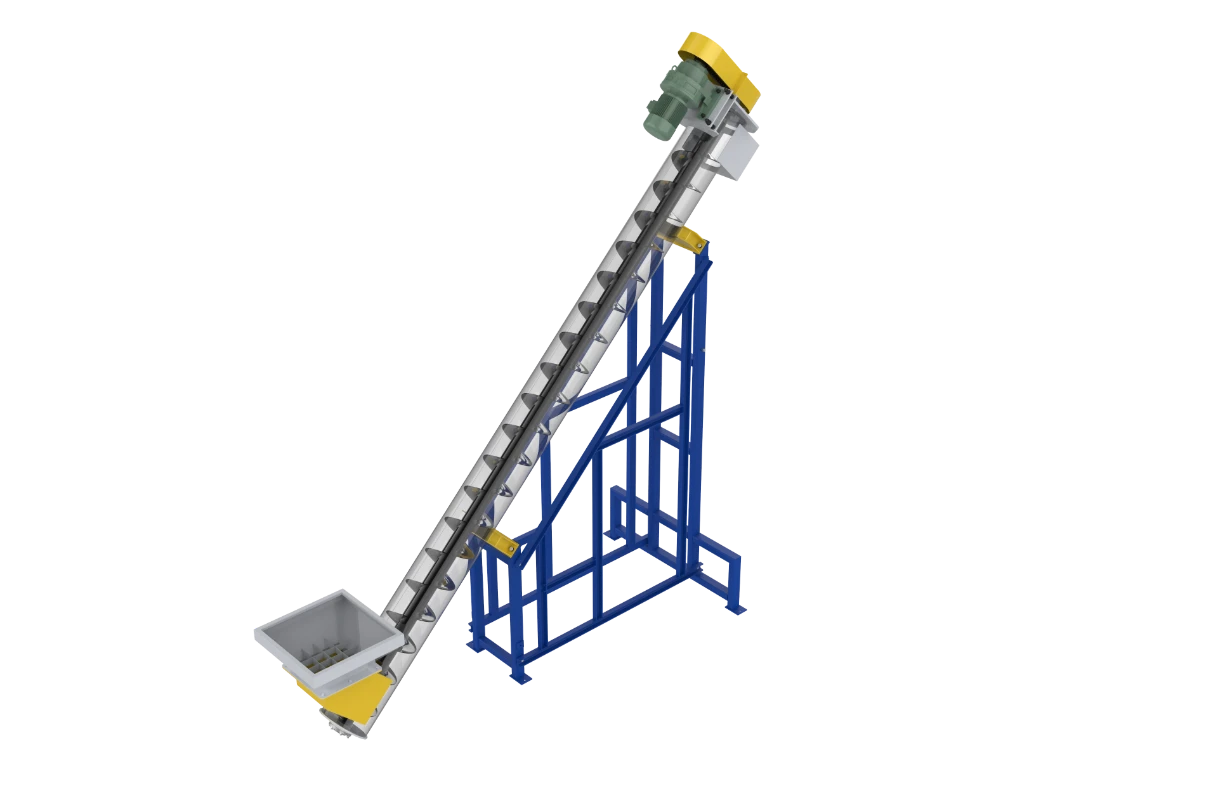

View Sorting SystemsStage 2: Size Reduction

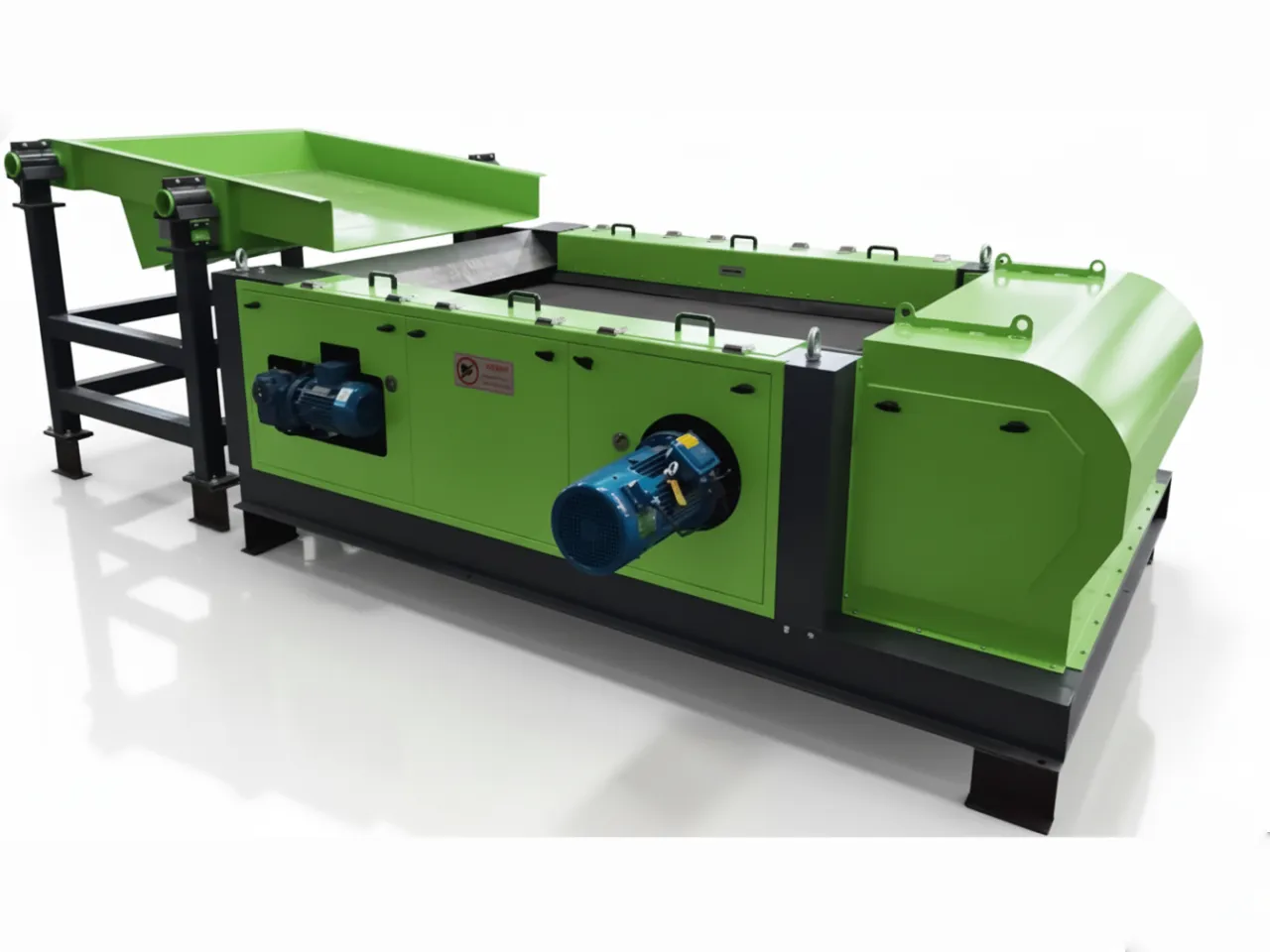

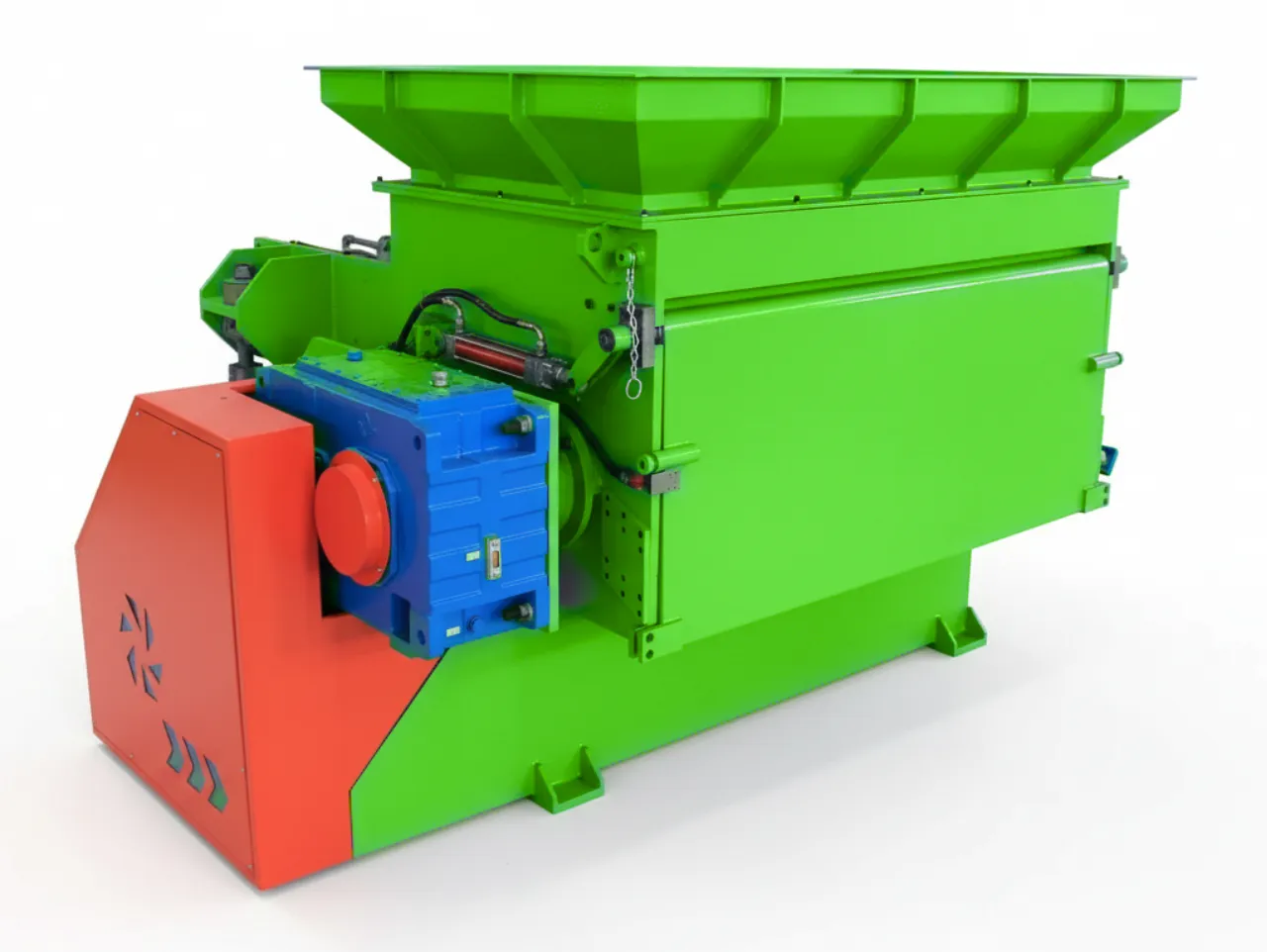

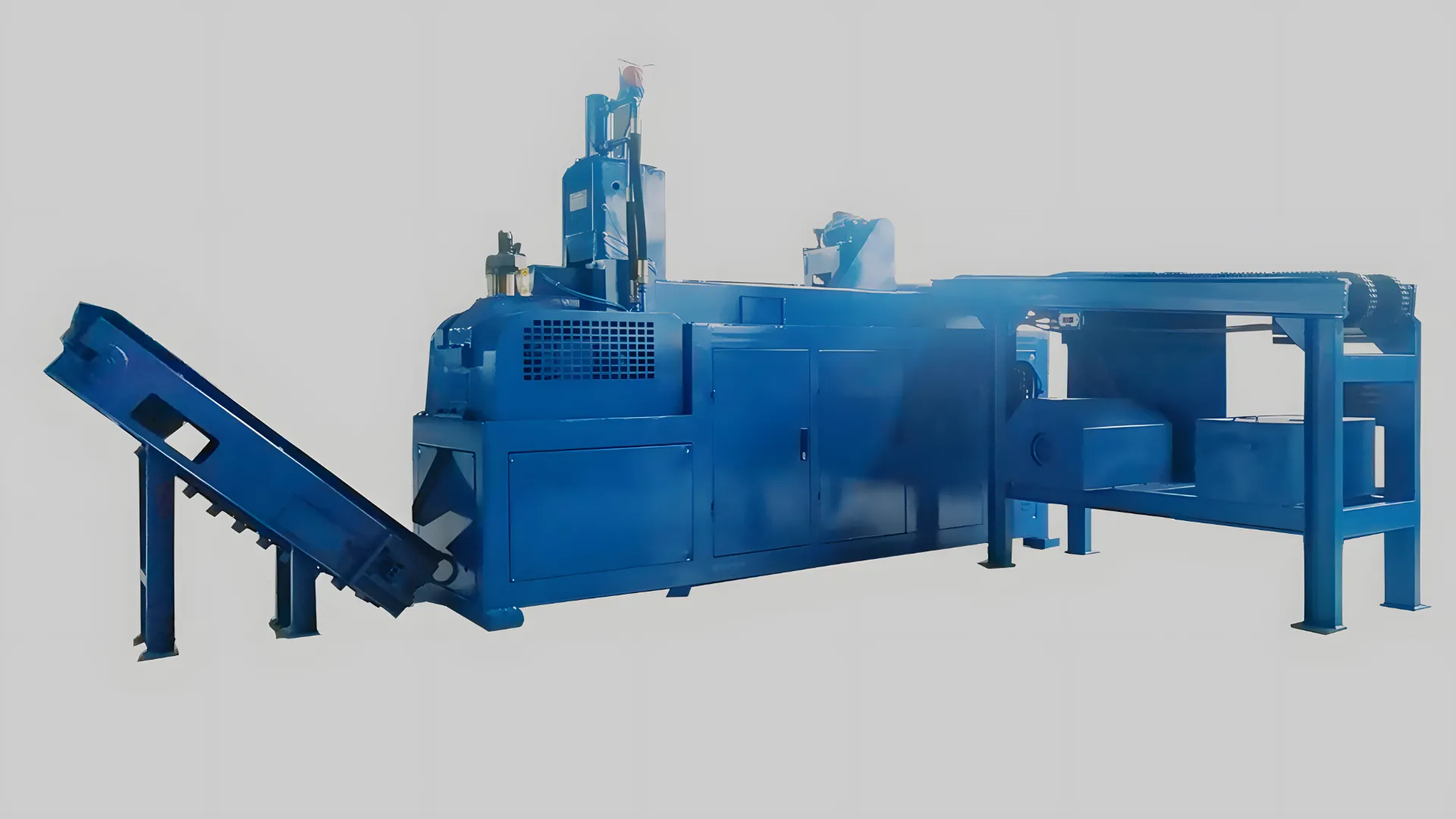

Industrial-grade shredders and crushers reduce plastic items into small, uniform flakes, increasing surface area for more effective cleaning and melting.

View Plastic Shredder Recycling MachinesStage 3: Washing & Purification

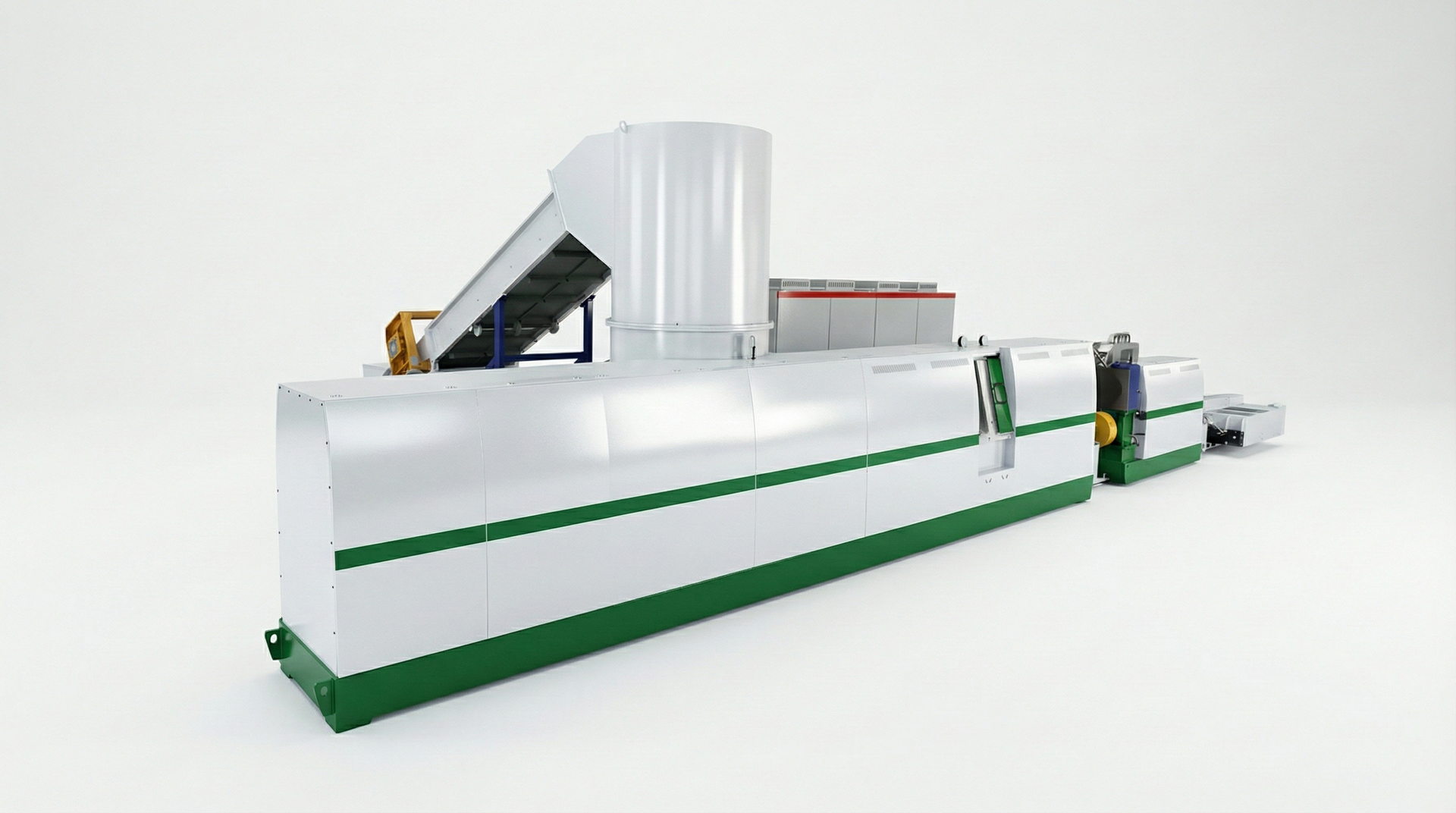

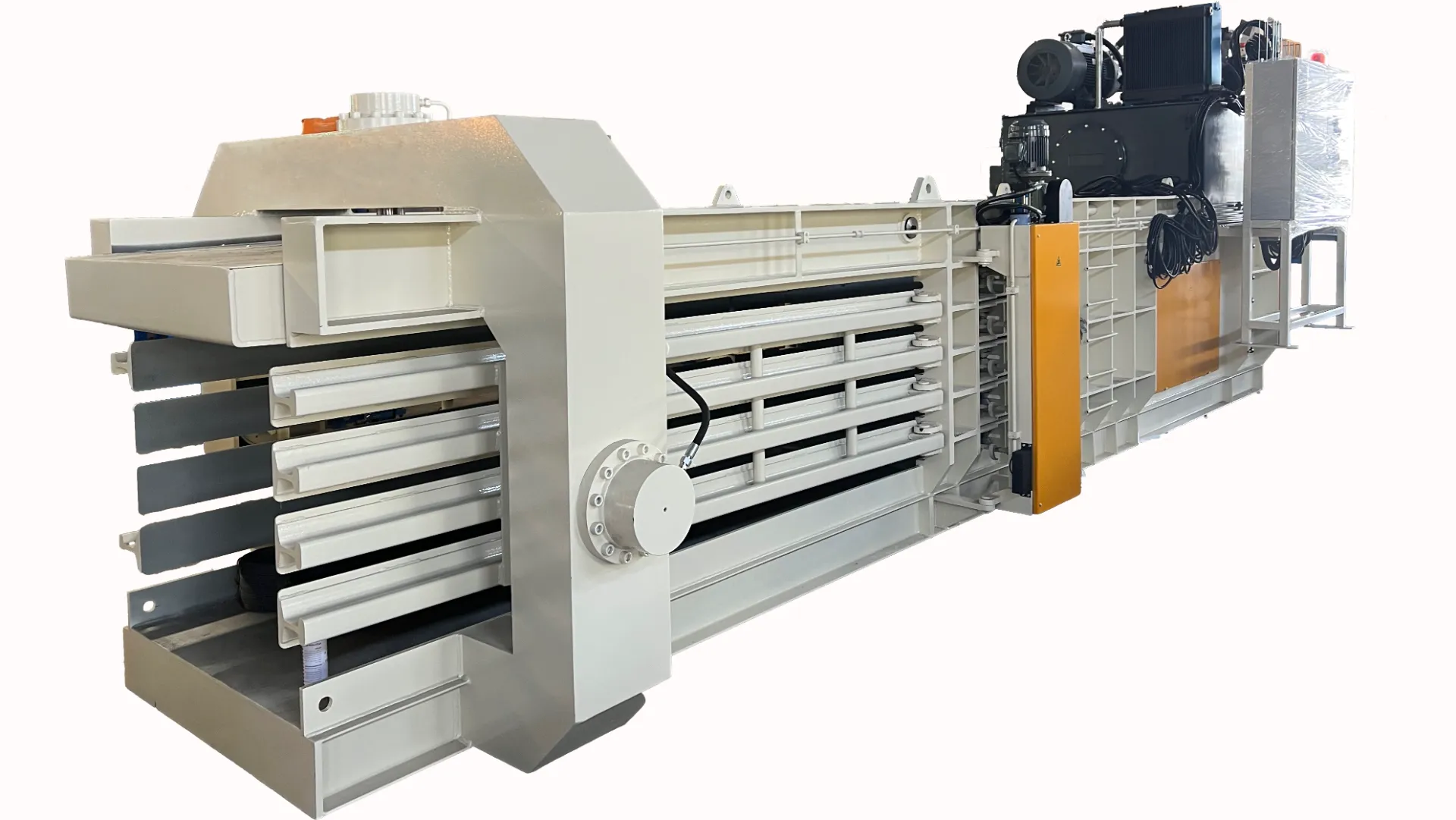

An intensive washing process using friction washers and float-sink tanks removes all dirt, labels, and adhesives to guarantee material purity.

View Washing LinesStage 4: Dewatering & Drying

A combination of mechanical and thermal drying systems reduces moisture content to below 1%, a critical step for producing high-quality, void-free pellets.

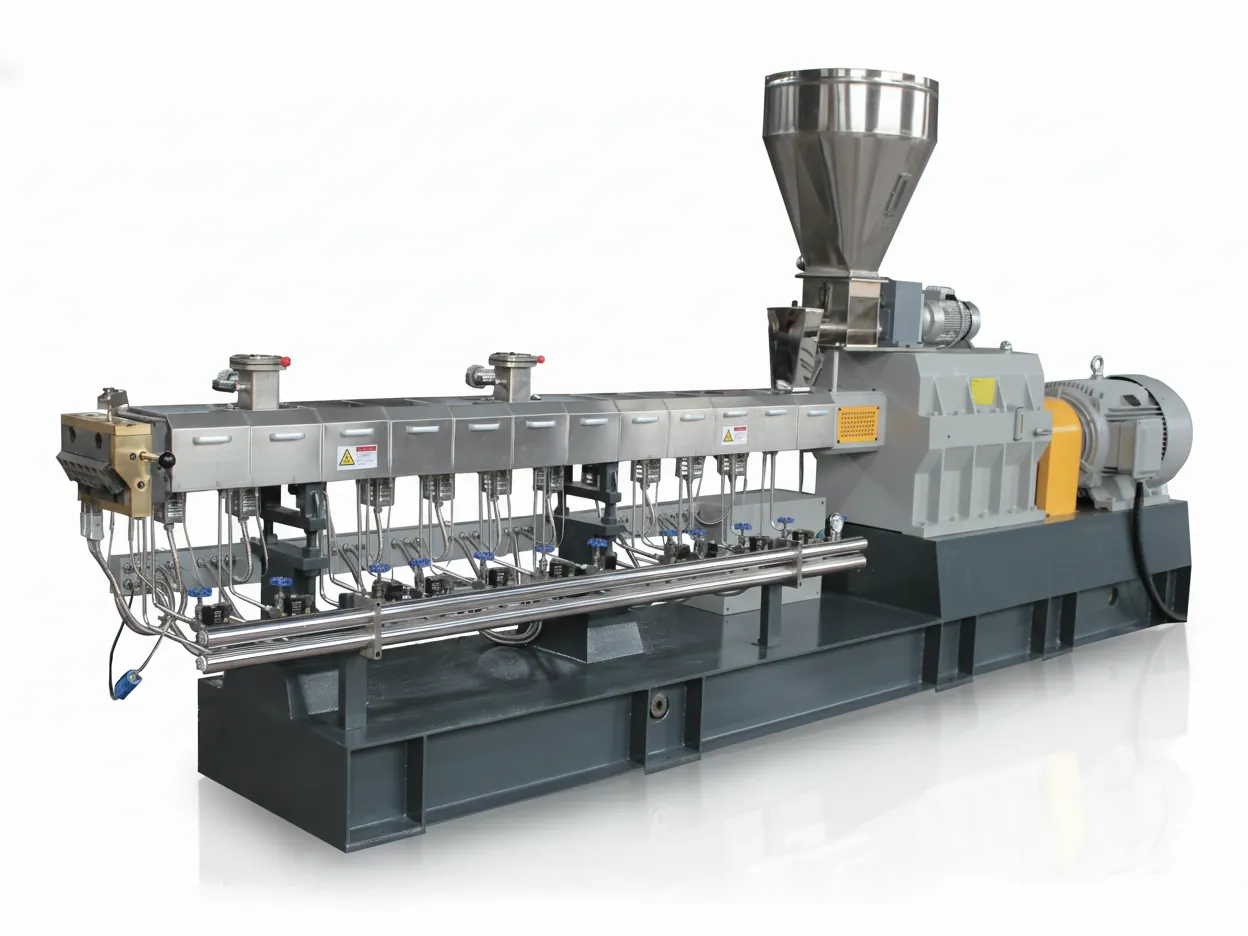

View Drying SystemsStage 5: Melting & Pelletizing

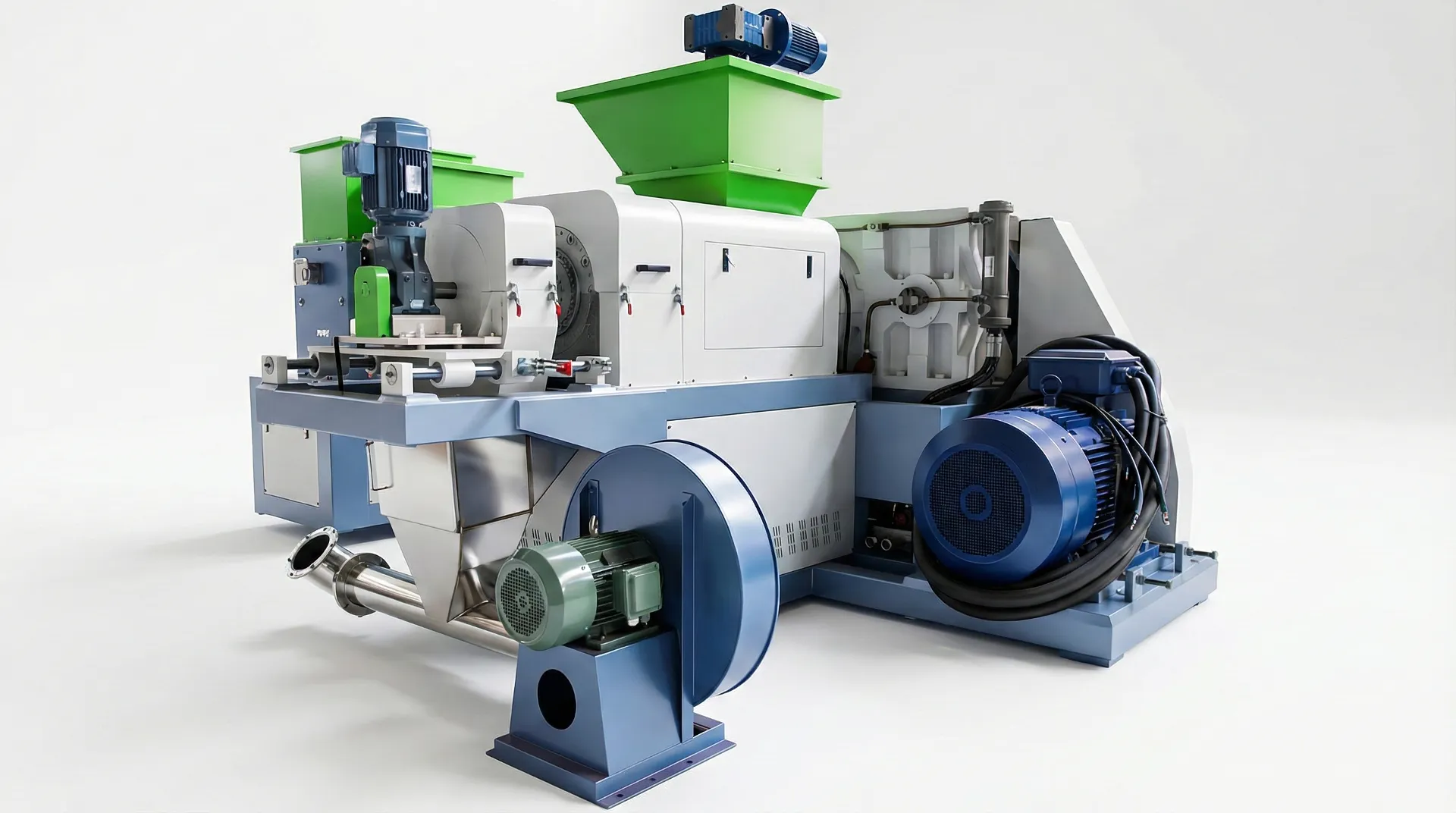

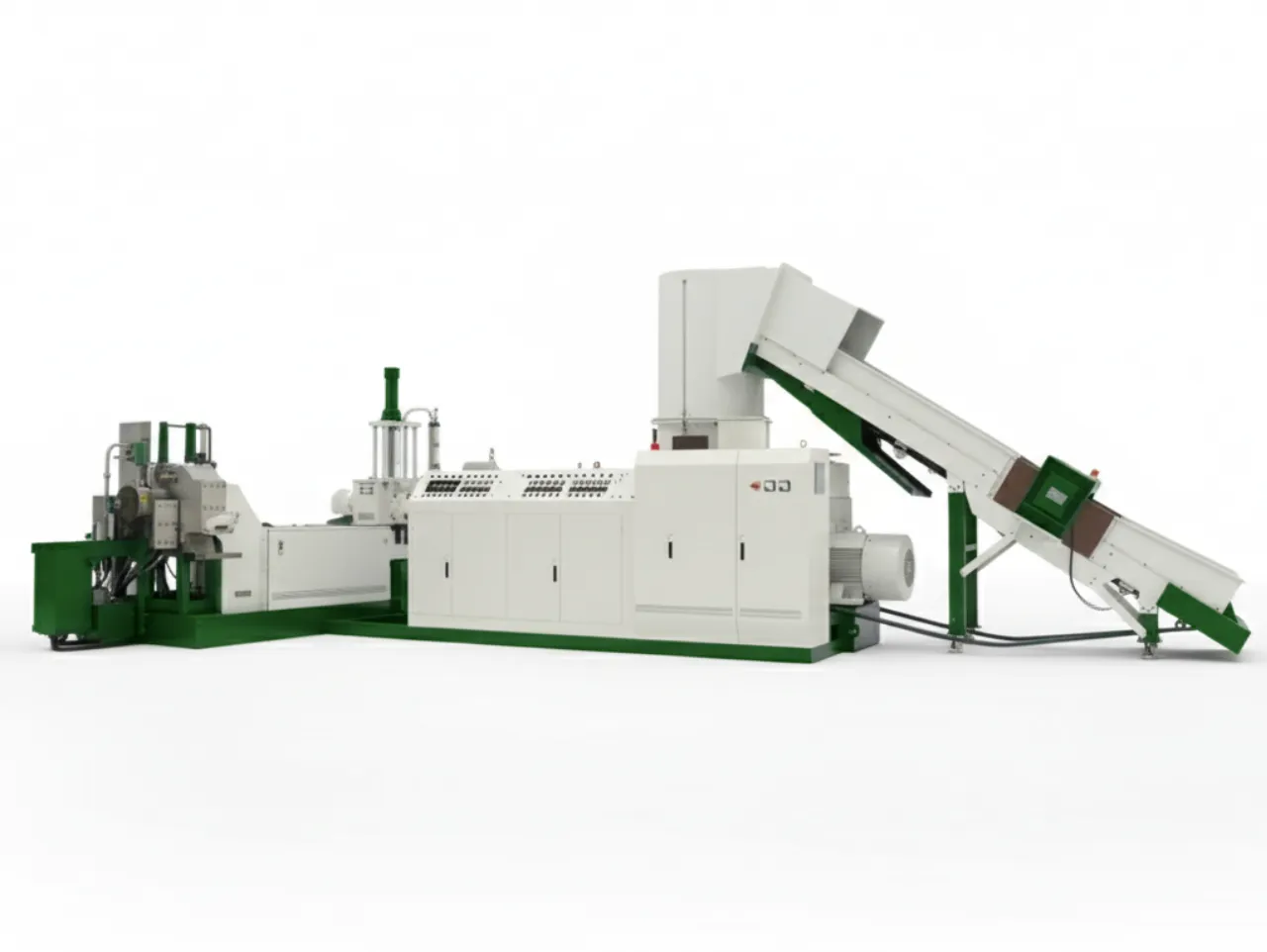

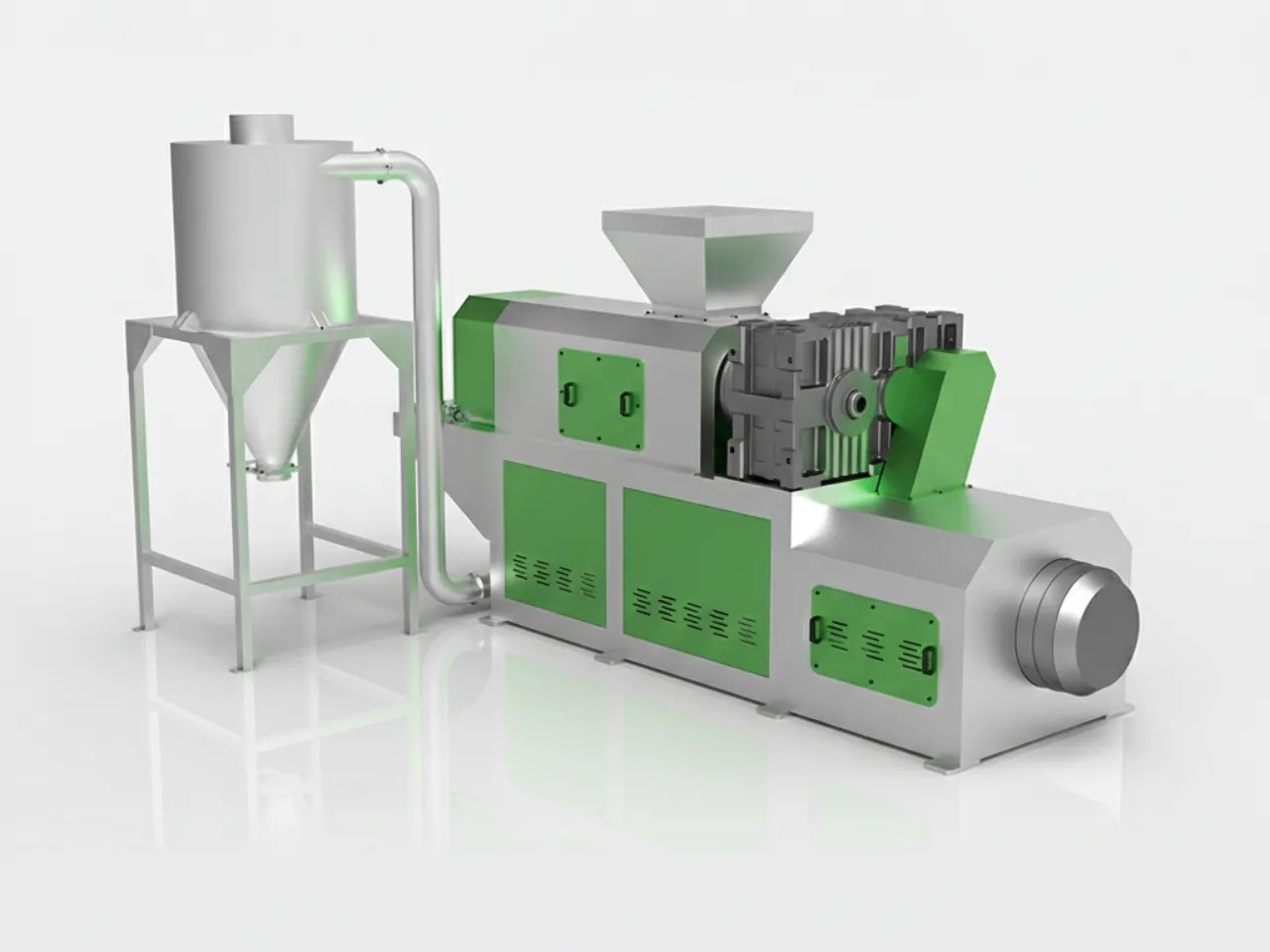

Clean, dry flakes are melted, filtered, and extruded into uniform strands, then precisely cut into consistent, high-grade pellets ready for manufacturing.

View Plastic Pelletizing MachinesFinal Product: High-Quality Recycled Plastic Pellets

The result of our advanced process: clean, uniform, and high-purity recycled pellets, creating a valuable resource from waste materials.

See ResultsIndustries & Feedstocks We Serve

From post-consumer films to rigid packaging and PET bottles, our engineering teams design recycling lines that match each material stream, compliance requirement, and downstream product target.

PET Wet Crushing

Pre-washing and wet crushing solutions for PET bottles to remove labels, dirt, and contaminants before downstream washing and pelletizing.

Request a PET Line ProposalFilm Recycling Line Design

Complete PP/PE film recycling lines with high-efficiency friction washers, squeezers, and water-ring pelletizing for low-bulk films.

Request a Film Line LayoutRigid Plastic Recycling Lines

Heavy-duty shredders, wet granulators, and extrusion systems tuned for drums, crates, IBCs, and injection-grade regrind.

Request a Rigid Line ProposalMSW & C&I Sorting Systems

Front-end sorting, ballistic separation, and optical QC to turn mixed MSW or C&I streams into clean, polymer-specific fractions.

Request a Sorting System LayoutOur Machines & Facilities in Action

Frequently Asked Questions

What types of plastic can your machines process?

Our machines are highly versatile and can be configured to process a wide range of plastics, including rigid materials like HDPE and PP, as well as soft materials like PE, LDPE films, and woven bags. We provide customized solutions for specific materials like PET or highly contaminated waste streams.

Do you offer complete turnkey plant solutions?

Yes, providing turnkey solutions is our specialty. We manage the entire project from initial consultation and plant layout design to manufacturing, on-site installation by our engineers, commissioning, and comprehensive training for your staff.

What kind of after-sales support can I expect?

We offer lifetime after-sales support. This includes 24/7 technical assistance, a reliable global supply of spare parts to minimize downtime, and optional remote monitoring services to ensure your plastic recycling machines operate at peak performance.

What capacities do your recycling lines support?

Our modular lines typically cover 300–3,000 kg/h. We size throughput based on your incoming stream, contamination level, and target pellets. Explore key sections like shredding, washing, drying, and pelletizing to see typical ranges.

What is the typical lead time and installation schedule?

Manufacturing usually takes 45–90 days depending on configuration and capacity. On‑site installation and commissioning typically require 7–15 days, including operator training.

Can you customize the line to my layout and materials?

Yes. We tailor screw profiles, filtration, washing modules (de‑labeler, hot wash, water treatment), dewatering (squeezer/centrifuge/thermal), and pelletizing (strand or water‑ring) to your plant layout and polymers (HDPE, PP, PET, etc.).

What utilities and floor space are required?

Typical utilities include a 3‑phase industrial power supply (e.g., 380–480 V), closed‑loop cooling water, and compressed air. A 1 t/h line generally requires 300–600 m² depending on layout. A detailed utilities and footprint list is provided with the proposal.

What certifications and safety standards do you meet?

CE/UKCA compliance available; critical components use UL/IEC‑rated parts. We align with local electrical and safety codes where the plant is installed and supply full documentation (wiring diagrams, manuals, risk assessments).

What is included in a plastic recycling plant solution?

A turnkey plastic recycling plant typically includes sorting, shredding/granulation, washing, dewatering and drying, melt filtration, and pelletizing. See our complete recycling solutions for typical configurations and capacities.

How much does a plastic recycling machine cost?

Pricing depends on capacity, feedstock condition, and line configuration. If you send material photos, target kg/h, voltage, and available floor space, we will recommend the right plastic recycling machine configuration and provide a formal quotation.

Do you ship and install internationally?

Yes. We support EXW/FOB/CFR terms, arrange sea freight, and send certified engineers for on‑site installation, commissioning, and training worldwide.