Introduction:

In the realm of waste management, selecting the right shredder is paramount for efficient processing and recycling. Whether you’re dealing with plastic, tires, or hard drives, having the appropriate shredding machine can streamline operations and maximize resource utilization. In this comprehensive guide, we’ll delve into the key factors to consider when choosing a shredder tailored to your specific waste processing requirements.

Understanding Your Shredding Needs:

Before diving into the vast array of shredder options available, it’s crucial to assess your waste processing needs meticulously. Identify the type and volume of materials you intend to shred, as well as any specific requirements such as particle size and throughput capacity. This initial step will serve as the foundation for selecting the most suitable shredding machine for your operations.

Types of Plastic Shredders:

Shredding machines come in a variety of types, each tailored for different materials and purposes. Plastic shredders can be broadly categorized by their size, functionality, and application. Here’s a breakdown of some common types:

Based on Size:

Small/Benchtop Shredders:

Compact and ideal for small-scale operations, hobbyists, and personal use. Typically used for shredding small quantities of plastic, like bottles and containers.

Industrial Shredders:

Larger and more powerful units designed for high-volume processing in manufacturing and recycling facilities. They can handle a wider variety of plastics, including bulky items and rigid materials.

Based on Functionality:

Single-Shaft Shredders:

These machines feature a single shaft with blades that rotate at a slow speed, making them ideal for shredding hard and thick materials. Single-shaft shredders are typically used for plastic film, large pieces of plastic, and other tough materials.

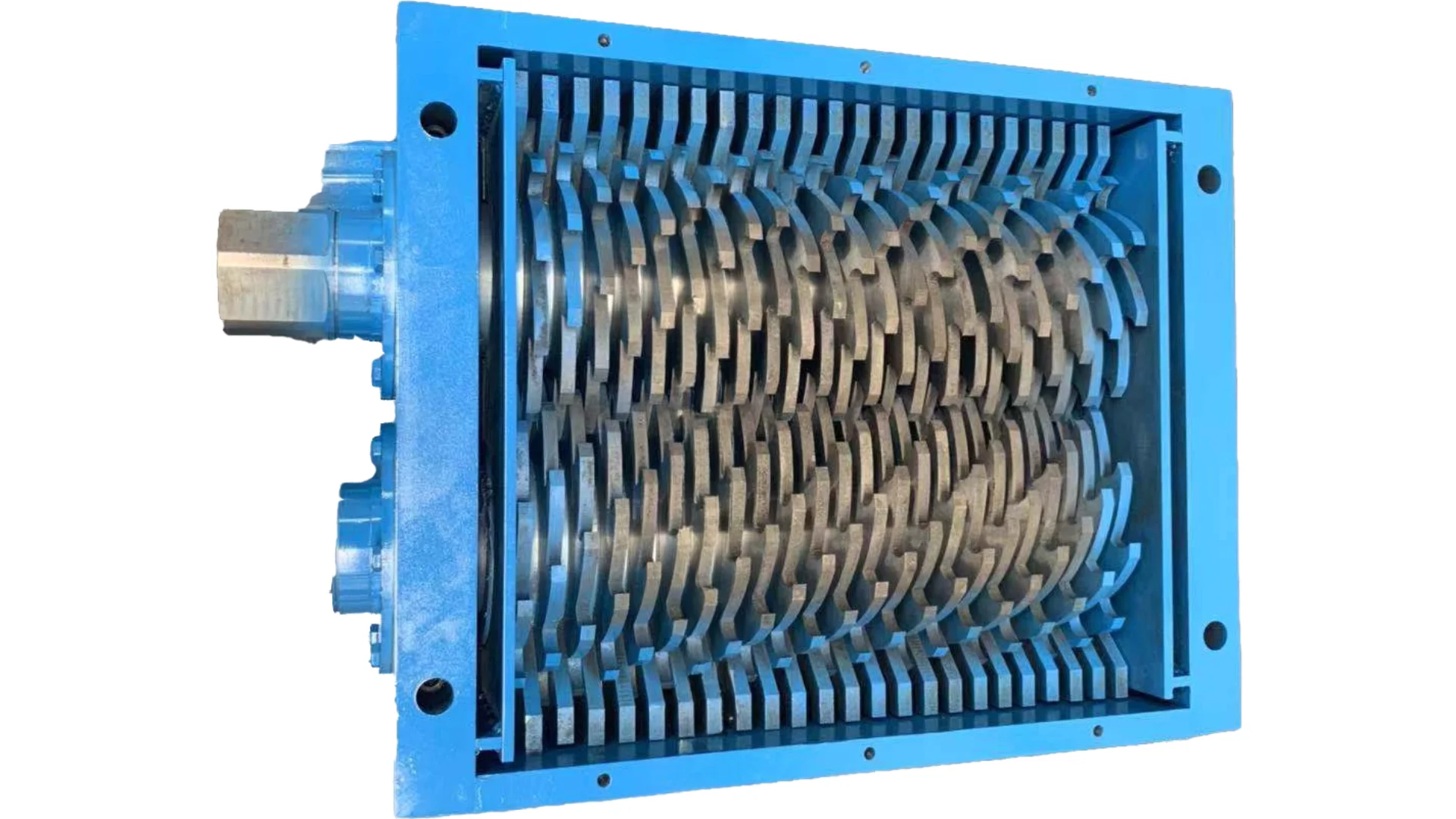

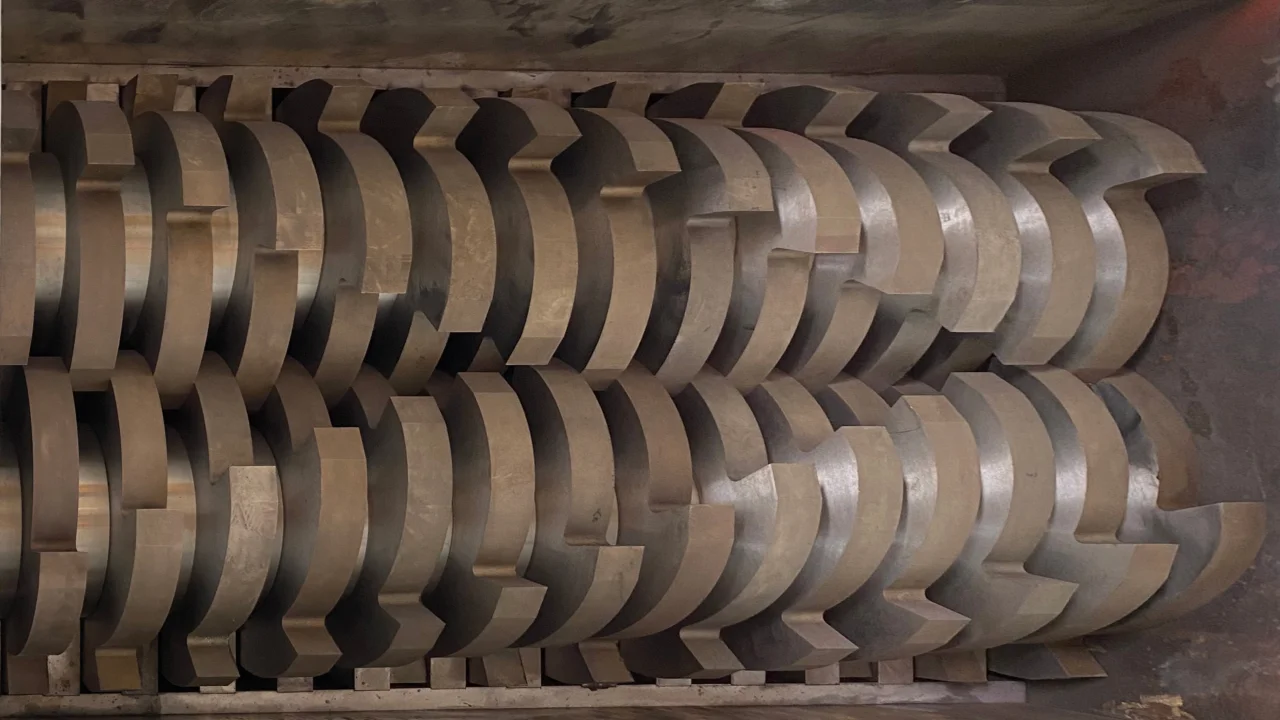

Dual-Shaft (or Twin-Shaft) Shredders:

Dual-shaft shredders have two parallel shafts with interlocking cutting discs. This design allows them to efficiently shred large volumes of plastic with high torque, making them suitable for a variety of plastic types including bulky containers and larger objects.

Four-Shaft Shredders:

These shredders have four shafts working at varying speeds, which provide high throughput and finer shredding. They are often used when precise size reduction is required, and they capable of processing very tough and large plastic items. Often used in demanding industrial applications.

Granulators:

Granulators are high-speed machinery used primarily for size reduction of smaller plastic scraps and residues. They operate with a cutting chamber equipped with rotating knives and are typically used after other shredding steps in the recycling process.

Based on Application:

Paper Shredders:

Designed specifically for destroying documents to protect privacy and confidentiality. These range from personal sizes to large, industrial models and include strip-cut, cross-cut, and micro-cut variants.

Plastic Shredders:

These are used to recycle plastic materials like PET bottles, plastic bags, and packaging films. They help in reducing the volume of plastic waste and prepare it for recycling.

Wood Shredders (or Chippers):

These machines are used to reduce wood into smaller components, like chips or sawdust, which can be used for wood pulp, landscaping, or as biomass for energy production.

Tire Shredders:

Specialized in handling and recycling old tires, these machines can process tires into rubber chips or crumb rubber, which can then be used in paving projects, playground surfaces, or new rubber products.

Electronic Waste Shredders:

These are designed to handle electronic devices such as computers, mobile phones, and televisions, helping in the recycling process and safe disposal of potentially hazardous materials.

Industrial Shredders: Capable of handling a wide range of materials, including paper, plastics, wood, and metals. These are used in manufacturing processes, waste management, and recycling centers.

Metal Shredders:

Specifically built to shred large metal parts or sheets. These shredders play a crucial role in metal recycling industries by breaking down scrap metal into smaller pieces that are easier to process and recycle.

Document Shredders:

Similar to paper shredders but often designed for higher security standards, as they might be used in governmental or financial institutions to shred confidential papers into very fine particles.

Food Waste Shredders:

These are used in industrial kitchens, food processing plants, or by waste management companies to reduce the size of organic waste, which can then be composted or processed further.

Mobile Shredders:

Portable shredding machines that can be transported to various locations for on-site shredding of materials, offering convenience and flexibility.

Cardboard Shredders:

Designed to recycle cardboard boxes and sheets into packaging material or void fill material for shipping purposes.

Computer / Hard Drive Shredders:

For securely destroying computer hard drives, the most suitable type of shredder is a hard drive shredder specifically designed for electronic media destruction.

Horizontal Shredders:

A horizontal shredder is a type of industrial equipment designed for the efficient processing and size reduction of a variety of materials. These machines are particularly useful for shredding long and bulky materials such as pallets, pipes, and large sheets of plastic or wood. The horizontal orientation of the shredding mechanism allows these items to be fed into the machine more easily compared to vertical shredders.

Each type of shredding machine is designed to meet specific needs and is equipped with features to efficiently handle the materials intended for shredding.

Key Considerations for Selection:

When choosing a shredder for your waste processing needs, several key factors should be taken into account:

- Material Compatibility: Ensure that the shredder is capable of handling the specific materials you intend to process, including size, shape, and density.like PVC or HDPE.

- Throughput Capacity: Evaluate the shredder’s capacity to handle the expected volume of materials efficiently without causing bottlenecks in your operations.

- Particle Size: Determine the desired particle size or shred profile required for your recycling processes, as different shredders offer varying degrees of shredding precision.

- Maintenance and Durability: Consider the shredder’s build quality, maintenance requirements, and reliability to minimize downtime and maximize operational efficiency.

- Safety Features: Prioritize shredders equipped with safety features such as emergency stop buttons, safety interlocks, and overload protection mechanisms to ensure a safe working environment for operators.

- Noise Levels: Industrial shredders can be quite loud.

- Output Size: Shredders offer varying output sizes, from coarse shreds to fine granules.

Conclusion:

Selecting the right shredder for your waste processing needs is a critical decision that can significantly impact the efficiency and effectiveness of your recycling operations. By understanding your requirements, exploring the available options, and considering key factors such as material compatibility, throughput capacity, and safety features, you can make an informed choice that aligns with your objectives and enhances your overall waste management strategy. Invest in the right shredding machine today and embark on a sustainable journey towards a greener future.

FAQs:

Q: How do I know which type of shredder is best for my waste materials?

A: Start by identifying the types of waste materials you’ll be processing, then choose a shredder specifically designed to handle those materials efficiently.

Q: What maintenance tasks are required for shredders?

A: Maintenance tasks for shredders typically include cleaning, blade sharpening, and lubrication to ensure optimal performance and longevity.