The global drive towards a circular economy has placed unprecedented importance on efficient plastic recycling. As specialists in plastic recycling machinery, Rumtoo understands that the quality of recycled material is paramount. One of the workhorse technologies ensuring high purity levels in recovered plastics is the Sink-Float Separation Tank. This article delves into what these tanks are, how they operate, and why they are indispensable for modern recycling facilities.

What Exactly is a Sink-Float Separation Tank?

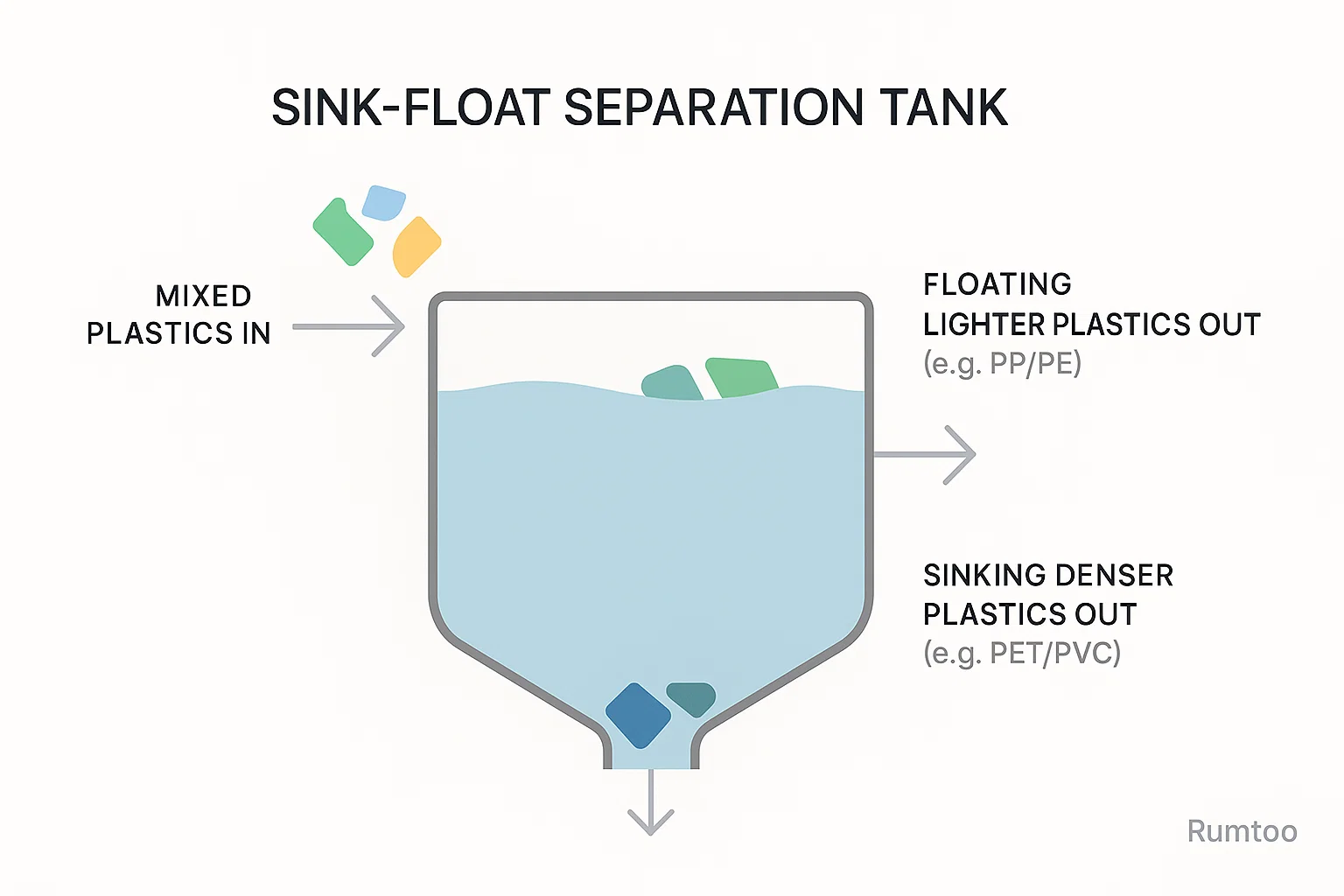

A Sink-Float Separation Tank is a piece of industrial equipment designed to separate different types of plastics (or other materials) based on their respective densities, typically using water as the separation medium. The fundamental principle is simple yet highly effective: materials denser than the liquid medium will sink, whilst those less dense will float. This process is crucial for segregating mixed plastic streams, which is a common challenge in post-consumer and post-industrial waste.

For example, in a mixed batch of PET bottles (Polyethylene Terephthalate) and their PP/PE (Polypropylene/Polyethylene) caps and labels, the PET, being denser than water, will sink. Conversely, PP and PE, being less dense than water, will float. This allows for their effective separation, a vital step in producing high-quality recycled feedstock.

How Does a Sink-Float Separation Tank Work? The Science of Separation

The operation of a Sink-Float Separation Tank leverages Archimedes’ principle. Let’s break down the typical workflow:

- Material Input: Pre-processed plastic flakes – often washed and shredded – are fed into one end of the tank. This pre-processing step is important as it ensures the material is of a suitable size and cleanliness for optimal separation.

- Immersion and Agitation: As the mixed plastics enter the tank filled with water (or occasionally a saline solution for finer density adjustments), they are gently agitated. This helps to ensure that all surfaces of the plastic particles are wetted and that trapped air is released, preventing less dense materials from being artificially dragged down.

- Density-Based Segregation:

- Sinking Fraction: Materials with a density greater than that of the separation liquid (e.g., PET, PVC in water) will gradually sink to the bottom of the tank.

- Floating Fraction: Materials with a density lower than that of the separation liquid (e.g., PE, PP in water) will float on the surface.

- Material Extraction:

- The floating materials are typically skimmed off the surface by rotating paddles or a slow-moving conveyor and directed to a separate discharge chute.

- The sunken materials are collected from the bottom of the tank, often by a screw conveyor or a drag-out conveyor, and transported to their own discharge point.

- Water Management: Modern Sink-Float Separation Tanks often incorporate water circulation and filtration systems. This not only conserves water but also removes fine contaminants, maintaining the efficiency of the separation process and the cleanliness of the water.

Diagram Suggestion: (Imagine a simplified side-view diagram here, illustrating the tank with an infeed point, water level, floating plastics being skimmed off the top by paddles, and sinking plastics being collected by a screw conveyor at the bottom. Arrows would indicate material flow and water circulation.)

Simplified Workflow Diagram:

[Mixed Plastic Flakes Infeed] --> [SINK-FLOAT TANK (Water Medium)] --> [Agitation Zone]

|

|--> [Floating Plastics (e.g., PE, PP) removed by Paddles/Skimmers] --> [Float Fraction Discharge]

|

|--> [Sinking Plastics (e.g., PET, PVC) collected by Conveyor] --> [Sink Fraction Discharge]

|

`--> [Water Recirculation & Filtration System]

Key Components and Design Considerations

A robust Sink-Float Separation Tank typically comprises:

- The Main Tank Body: Constructed from durable materials like stainless steel to resist corrosion and wear.

- Infeed Chute/Conveyor: For controlled introduction of materials.

- Agitators/Stirrers (Optional but Recommended): To ensure thorough wetting and separation.

- Surface Skimmers/Paddles: For removing the floating fraction.

- Bottom Discharge Mechanism: Screw conveyors or drag chains for extracting the sinking fraction.

- Water Inlet and Outlet Ports: For filling, draining, and recirculation.

- Filtration System: To maintain water quality and reduce operational costs.

- Control Panel: For managing motor speeds, water flow, and other operational parameters.

Applications in the Plastic Recycling Industry

Sink-Float Separation Tanks are versatile and find applications across various plastic recycling streams:

- PET Bottle Recycling: A cornerstone for separating PET bottle flakes (sink) from PP/PE caps and labels (float).

- Mixed Polyolefins Recycling: Separating PE from PP if a liquid medium with a density between the two is used (less common, usually density is set for water). More typically, separating polyolefins (PE, PP) from contaminants like PS, PVC, or ABS.

- Rigid Plastics Recycling: Segregating materials from mixed bales of post-consumer rigid packaging.

- WEEE (Waste Electrical and Electronic Equipment) Plastics: Separating different types of plastics found in electronic waste.

- Automotive Plastics Recycling: Isolating specific polymers from shredded automotive components.

The Advantages for Your Recycling Operation

Investing in a high-quality Sink-Float Separation Tank offers numerous benefits for industrial recyclers:

- Enhanced Purity of Recyclate: Achieves high levels of separation, leading to a more valuable end-product.

- Increased Efficiency: Automates a critical separation step, reducing manual labour and processing time.

- Cost-Effectiveness: Relatively low operational costs, especially with efficient water management systems.

- Versatility: Can handle a wide range of plastic types and contamination levels.

- Environmental Compliance: Contributes to better resource utilisation and reduces landfill burden.

- Improved Profitability: Higher purity recyclates command better market prices.

Choosing the Right Sink-Float Separation Tank for Your Needs

When considering a Sink-Float Separation Tank, industrial buyers should evaluate:

- Throughput Capacity: Matching the tank’s processing capability to your facility’s volume.

- Material Types: Ensuring the design is optimised for the specific plastics you process.

- Separation Efficiency: Look for designs that minimise cross-contamination between sink and float fractions.

- Footprint and Integration: How the tank will fit into your existing recycling line.

- Water Consumption and Management: Features for water conservation and filtration are crucial for sustainable operation.

- Construction Quality and Durability: Opt for robust materials and proven engineering.

- Maintenance Requirements: Ease of access for cleaning and part replacement.

Rumtoo: Your Partner in Advanced Separation Technology

At Rumtoo, we specialise in providing state-of-the-art plastic recycling machinery, including highly efficient Sink-Float Separation Tanks. Our designs prioritise reliability, separation accuracy, and operational efficiency to help your facility maximise the value of your recycled materials. We understand the nuances of plastic recycling and can advise on the best solutions to meet your specific operational requirements.

To learn more about our range of separation solutions and how they can benefit your operations, please explore our Sink-Float Separation Tank page or contact our technical sales team for a consultation.

Conclusion

The Sink-Float Separation Tank is more than just a piece of equipment; it is a cornerstone of effective plastic recycling. By efficiently separating plastics based on density, these tanks play a vital role in transforming mixed plastic waste into valuable, high-purity raw materials ready for their next life. For recycling professionals aiming to enhance their output quality and operational efficiency, understanding and investing in the right sink-float technology is a clear step towards a more profitable and sustainable future.