Advanced Plastic Recycling Machines

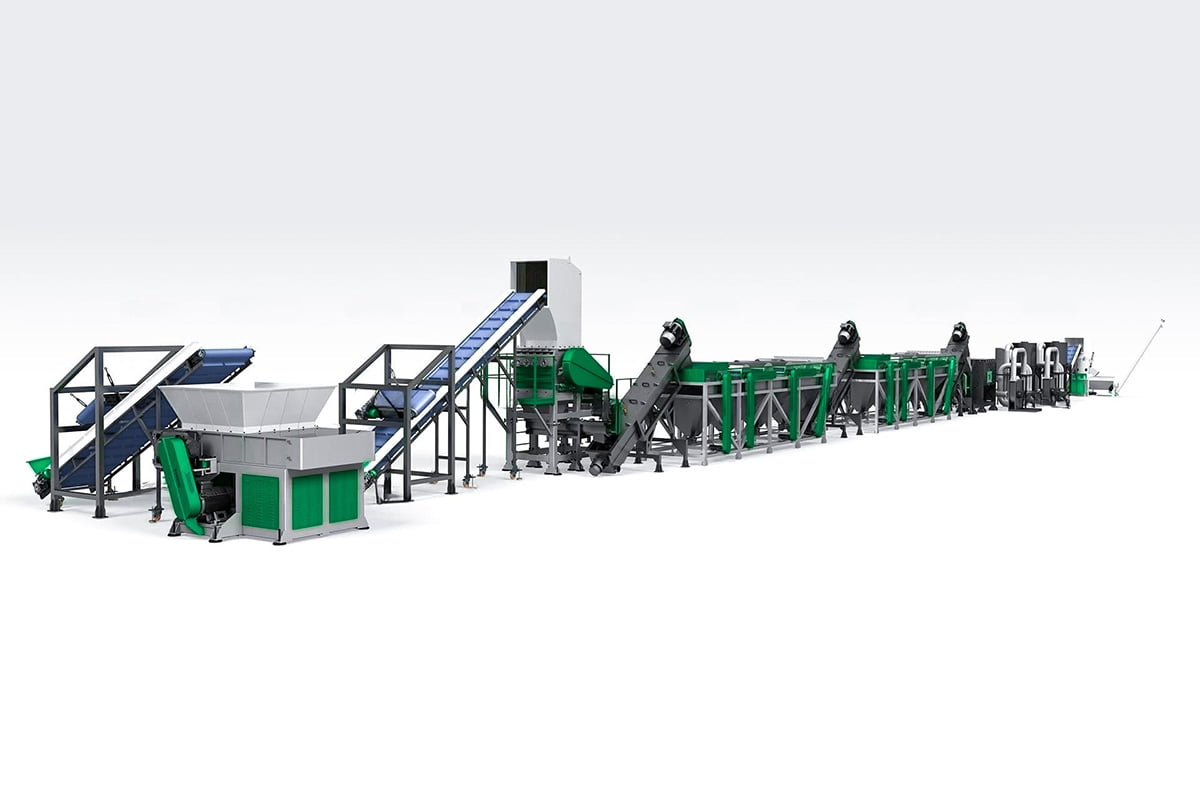

Discover our industrial-grade plastic recycling machines, engineered into complete turnkey lines. We provide efficient solutions to transform plastic waste into high-value, reusable pellets.

Get a Custom QuoteWhy Choose Our Recycling Machines?

High Throughput & Efficiency

Our machines are engineered for maximum processing capacity, ensuring a smooth, continuous workflow that boosts your productivity and reduces operational costs.

Learn MoreEnergy-Efficient Systems

Designed to minimize power and water consumption, our eco-friendly systems lower your operational costs and significantly reduce your carbon footprint.

Learn MoreSuperior Output Quality

Advanced multi-stage purification, filtration, and degassing processes result in high-purity, market-ready pellets suitable for premium applications.

Learn MoreIntelligent PLC Control

User-friendly touch screen interfaces provide one-touch control of the entire line, simplifying operation and real-time performance monitoring.

Learn MoreRobust & Durable Construction

Built with high-grade, wear-resistant alloys and heavy-duty components designed to withstand 24/7 industrial operation and ensure long-term reliability.

Learn MoreGlobal Support & Service

Our expert team provides comprehensive support including installation, commissioning, staff training, and reliable spare parts supply worldwide.

Learn MoreOur 6-Stage Plastic Recycling Process

Stage 1: Sorting & Separation

Raw plastic waste is sorted to remove contaminants. Advanced systems separate plastics by type and color to ensure the highest purity for downstream processing.

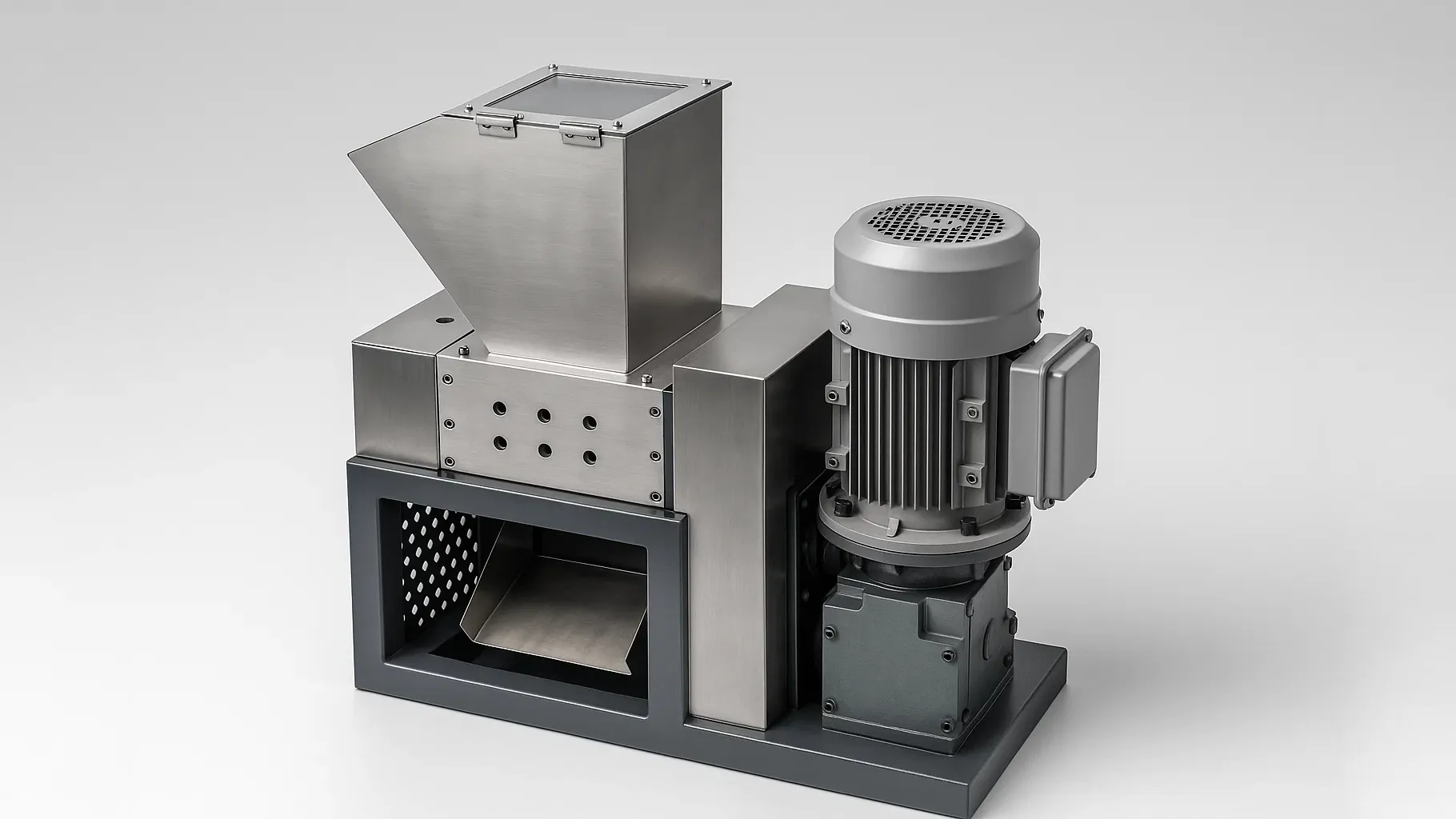

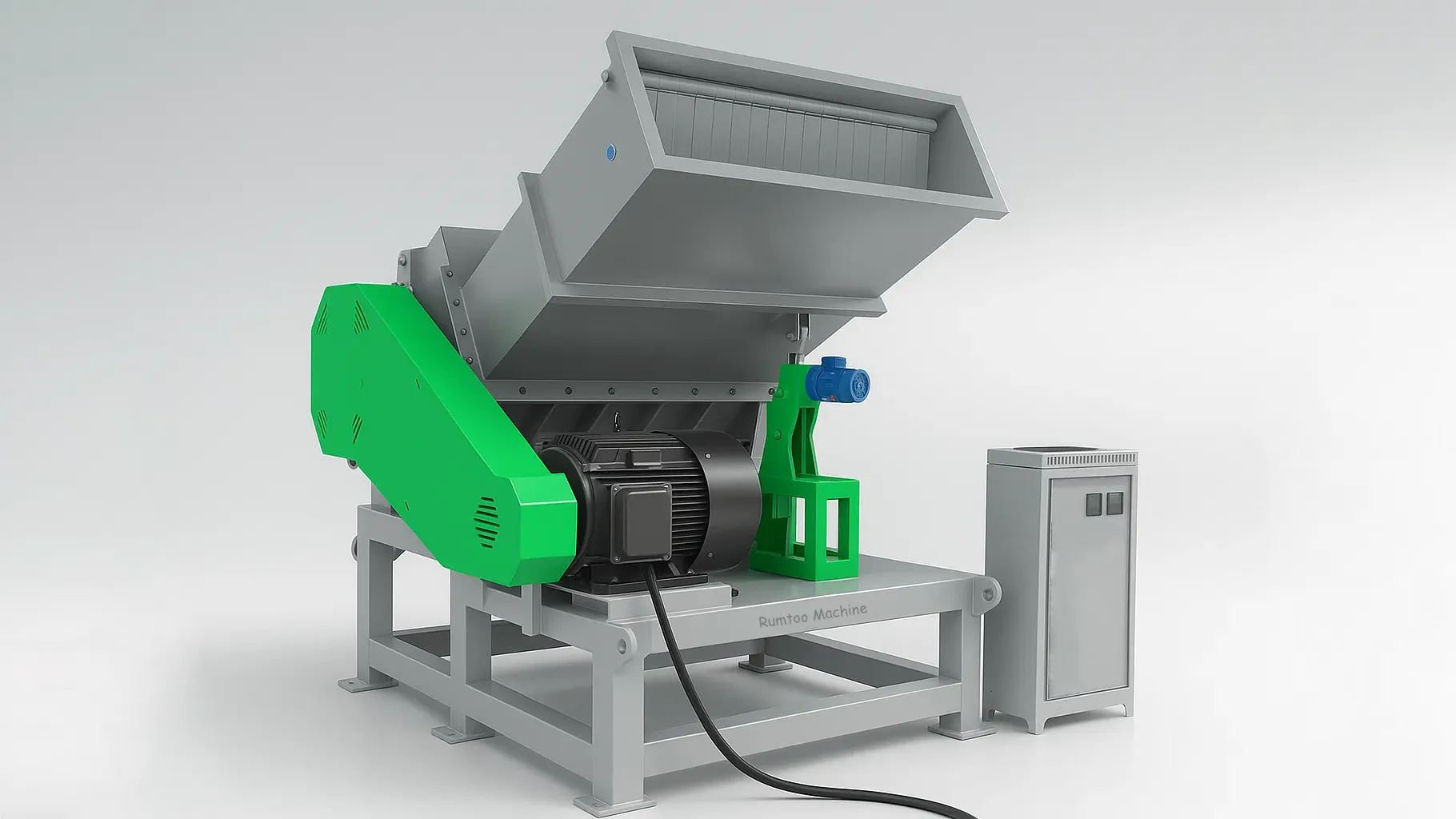

View Sorting SystemsStage 2: Size Reduction

Industrial-grade shredders and crushers reduce plastic items into small, uniform flakes, increasing surface area for more effective cleaning and melting.

View Shredding MachinesStage 3: Washing & Purification

An intensive washing process using friction washers and float-sink tanks removes all dirt, labels, and adhesives to guarantee material purity.

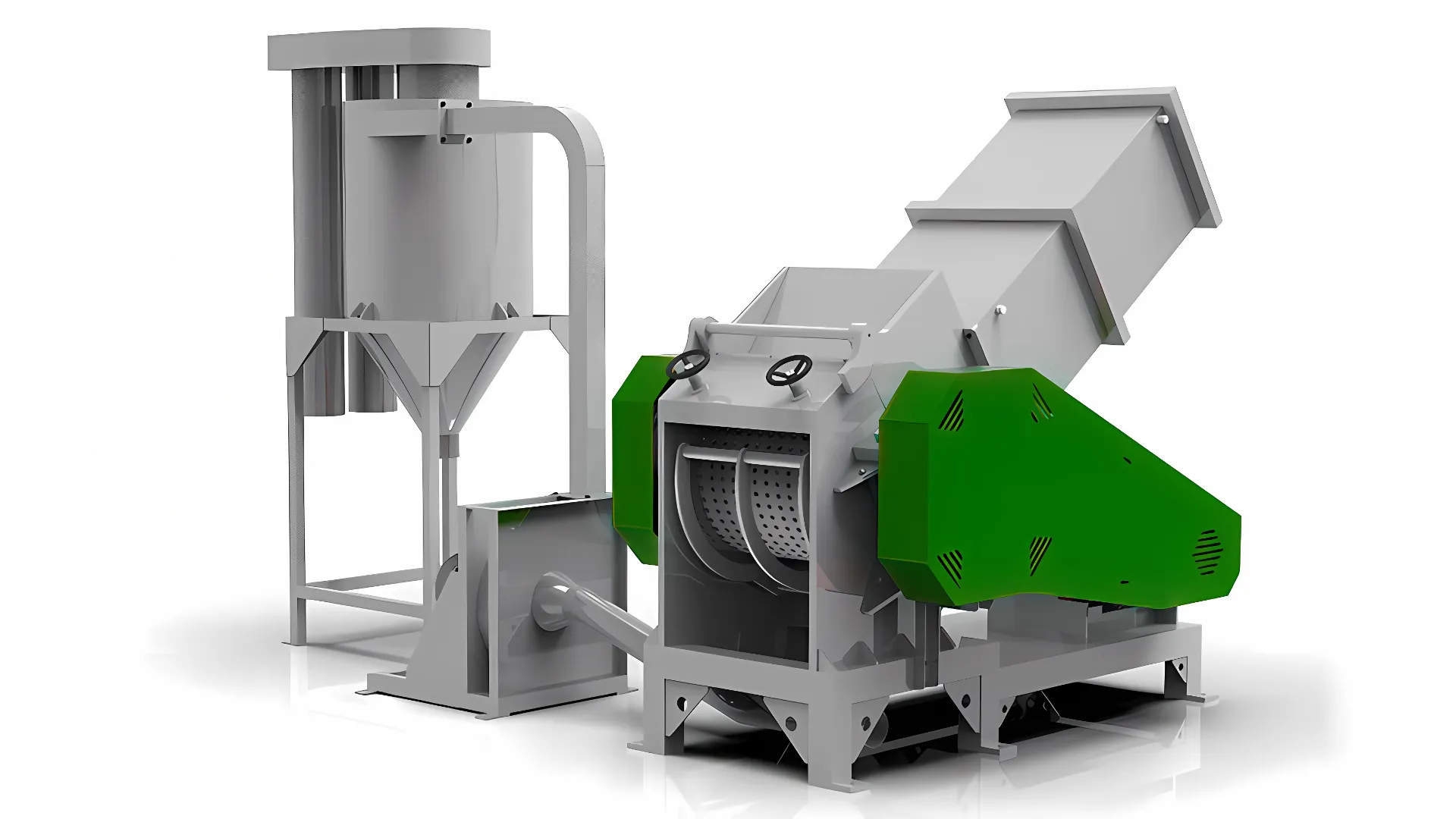

View Washing LinesStage 4: Dewatering & Drying

A combination of mechanical and thermal drying systems reduces moisture content to below 1%, a critical step for producing high-quality, void-free pellets.

View Drying SystemsStage 5: Melting & Pelletizing

Clean, dry flakes are melted, filtered, and extruded into uniform strands, then precisely cut into consistent, high-grade pellets ready for manufacturing.

View Pelletizing MachinesFinal Product: Quality Pellets

The result of our advanced process: clean, uniform, and high-purity recycled pellets, creating a valuable resource from waste materials.

See ResultsOur Machines & Facilities in Action

Frequently Asked Questions

What types of plastic can your machines process?

Our machines are highly versatile and can be configured to process a wide range of plastics, including rigid materials like HDPE and PP, as well as soft materials like PE, LDPE films, and woven bags. We provide customized solutions for specific materials like PET or highly contaminated waste streams.

Do you offer complete turnkey plant solutions?

Yes, providing turnkey solutions is our specialty. We manage the entire project from initial consultation and plant layout design to manufacturing, on-site installation by our engineers, commissioning, and comprehensive training for your staff.

What kind of after-sales support can I expect?

We offer lifetime after-sales support. This includes 24/7 technical assistance, a reliable global supply of spare parts to minimize downtime, and optional remote monitoring services to ensure your plastic recycling machines operate at peak performance.