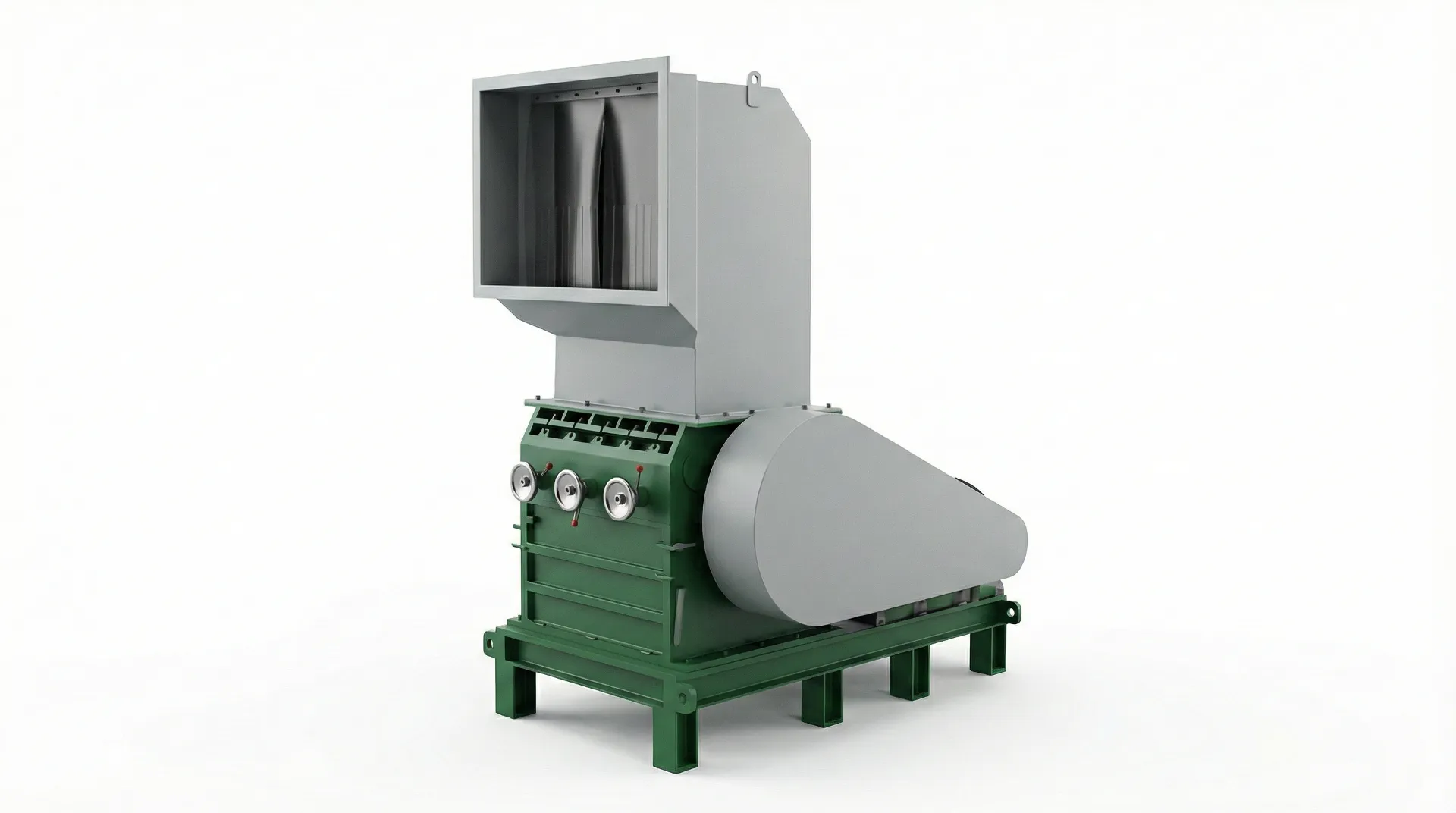

Standard Plastic Crusher

Standard-duty plastic crusher designed to reduce rigid plastics and bottles into uniform flakes for washing lines and downstream recycling processes. Suitable for PET, HDPE, PP, and more with stable, consistent output.

Looking for a compact model? View our Small Crusher Machine.

Why Choose Our Standard Plastic Crusher?

Reliable crushing performance for everyday plastic recycling applications

High Efficiency

Rapid cutting and processing capabilities for maximum productivity

Powerful Performance

Robust build with knife material options such as D2 / SKD-11 / DC53 (based on application)

Consistent Quality

Controlled screen sizing delivers consistent flake output for stable washing and extrusion feeding

Reliable Operation

1-year warranty with dedicated support team

Easy Maintenance

Hydraulic access for quick knife adjustments

Versatile Applications

Ideal for bottles and rigid plastics; films can be processed depending on thickness and feeding method

Key Features

Crusher-focused engineering for consistent flake output

- Premium Quality Construction

Built with heavy-duty materials for long-lasting performance - Advanced Cutting Technology

Double-scissor cut and V-shape knife arrays for optimal results - Customizable Screen Filters

Ranging from 10mm to 100mm for various particle sizes - Hydraulic Access System

Easy maintenance and knife adjustment capabilities - High-Speed Processing

400-600 rpm operating speeds for efficient production - Multiple Model Options

RTM-ST-600-A, RTM-ST-800-A, RTM-ST-1000-A, RTM-ST-1200-A for different throughput needs

Technical Specifications

Key specifications for standard-duty plastic crusher models

| Model | Rotor Diameter | Rotor Width | Rotating Speed | Approx. Output | Motor Power |

|---|---|---|---|---|---|

| RTM-ST-600-A | ⌀450mm | 600mm | 400-600 rpm | 300 kg/h | Custom |

| RTM-ST-800-A | ⌀500mm | 800mm | 400-600 rpm | 600 kg/h | Custom |

| RTM-ST-1000-A | ⌀600mm | 1000mm | 400-600 rpm | 900 kg/h | Custom |

| RTM-ST-1200-A | ⌀700mm | 1200mm | 400-600 rpm | 1200 kg/h | Custom |

Note: Output varies by material type, wall thickness, feeding method, and screen size. Contact us with your material photos and target flake size for an accurate recommendation.

Working Principle

How the crusher reduces plastic scrap into uniform flakes for downstream recycling

Material Input

Plastic materials are fed into the cutting chamber

Rapid Cutting

High-speed rotor with heavy-duty knives processes the material

Size Control

Screen filter ensures consistent particle size

Uniform Output

High-quality uniform flakes ready for further processing

Applications

Common crushing applications for producing uniform flakes before washing or downstream recycling

- PET Bottle Recycling

- Plastic Container Processing

- Rigid Plastic Grinding

- Plastic Parts & Sprues

- Plastic Film Recycling

- Sheet & Tray Crushing

Product Showcase

See our standard plastic crusher in action

Get Your Quote Today

Contact us for pricing, specifications, and custom solutions

Frequently Asked Questions

What types of plastics can this crusher process?

Our standard plastic crushers can handle common recycling streams such as PET bottles, HDPE/PP containers, and various rigid plastics. For films, performance depends on thickness, feeding method, and screen size.

What is the warranty coverage for these machines?

All our Standard Plastic Crusher machines come with a 1-year limited warranty. Our support team is available to help with installation guidance, spare parts, and operation questions.

Can the crusher be customized for specific requirements?

Yes. Common options include different screen sizes (to control flake size), knife material and configuration, hopper design, and safety/maintenance features depending on the application.