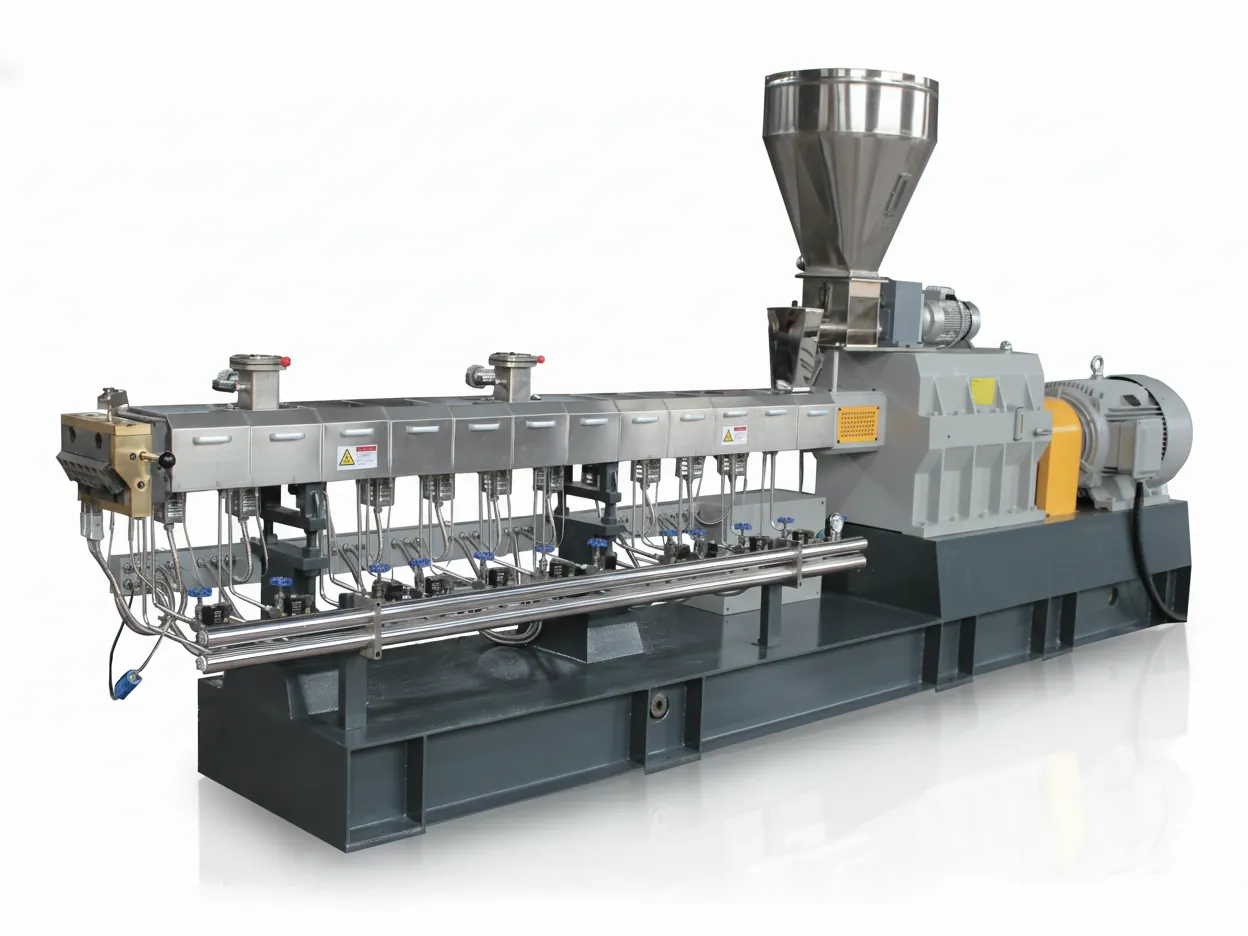

Twin Screw Compounding Extruder for Masterbatch & Fillers

Our twin-screw compounding line is a state-of-the-art solution engineered to conquer complex polymer processing challenges. It delivers unparalleled versatility and efficiency for plastics modification, masterbatch production, and compounding, helping you transform intricate formulations into high-value, homogeneous pellets.

맞춤형 솔루션 및 견적 받기작동 방식

Our modular and precision-engineered screw elements break down the complex process into a series of highly efficient, controllable steps.

- 1. 정밀 공급

미터링 시스템은 원료물질이 정확하고 일관되게 공급되도록 보장합니다.

- 2. 전달 및 녹이기

슈레드 요소는 가열된 구역을 통해 재료를 전달하여 빠르고 일관된 녹이기를 유도합니다.

- 3. 분산 및 분배 혼합

특수한 혼합 블록이 강력한剪切을 통해 추가제를 완벽히 분산시킵니다.

- 4. 일관성 및 발화물 제거

공기 배출구는 물과 발화물을 효율적으로 제거하여 펠릿 품질을 향상시킵니다.

- 5. 압력 및 Extrusion

안정된 압력이 구동헤드를 통해 녹은 폴리머의 일관된 줄을 Extrusion합니다.

- 6. 저온 및 펠릿화

줄은 고속 펠릿화기에 의해 일관된 크기의 펠릿으로 쪼개집니다.

핵심 장점

- 고급 모듈식 설계

Customize everything from screw configurations to pelletizing methods. One machine adapts to multiple processes.

- 강력한 토크 및 속도

Multiple series available, from standard to ultra-high torque, powered by premium VFDs from brands like Siemens and ABB.

- 정밀 자동화 제어

Equipped with OMRON or RKC intelligent temperature controllers with PID self-optimization for pinpoint accuracy.

- 신뢰할 수 있는 세계적인 구성 요소

Key components are sourced from trusted global brands like NSK, Schneider, and Siemens for long-term reliability.

耐久성을 위한 설계

요구되는 생산을 견딜 수 있도록 설계되었습니다.

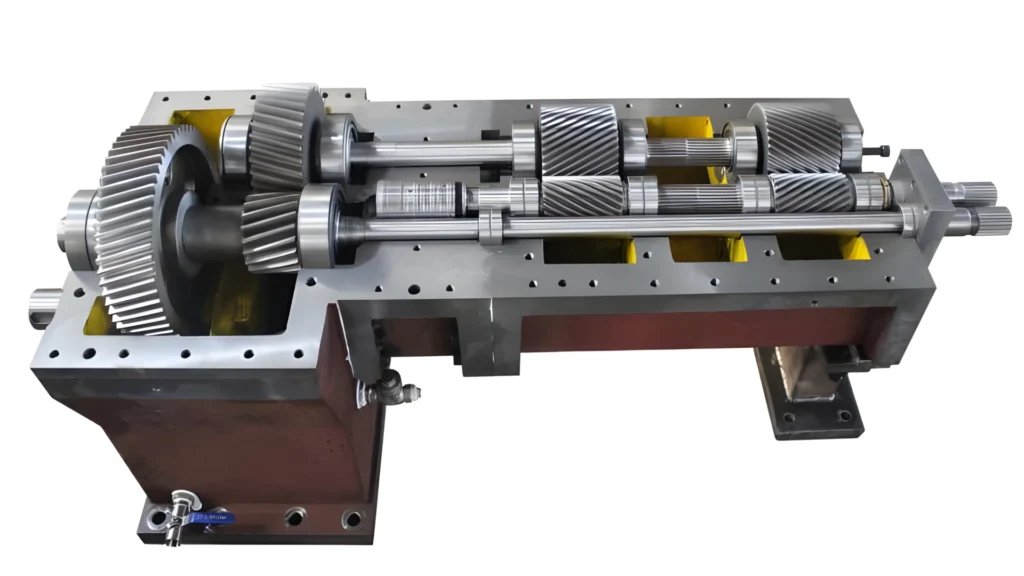

Our commitment to reliability is evident in every component. The heart of the machine, a high-torque distribution gearbox, is built with a significant safety margin, precision-machined gears, and imported key bearings for unmatched stability.

The standard bi-metallic barrel, featuring a wear-resistant alloy liner, is engineered for high performance, ensuring your investment is protected for the long term.

문제를 기회로 변환하세요

Conventional polymer processing is filled with obstacles. Our twin-screw line provides the direct solutions you need.

- 문제점: 불일관된 혼합 및 품질

해결책: Innovative, co-rotating, self-wiping screw elements guarantee exceptional mixing and dispersion for batch-to-batch consistency.

- 문제점: 재료 적응성이 좋지 않음

해결책: The modular screw design allows for rapid reconfiguration, making it easy to switch between diverse formulations and polymers.

다양한 응용 분야

- 기능적 마스터바치

- 폴리머 합성

- 생분해 플라스틱

- 강화 플라스틱

- 케이블 컴포운드 및 TPE

- 재활용 플라스틱 개선

- 고온 감수성 재료

- 반응 Extrusion

기술 사양

| 모델 | 슬리브 지름 (mm) | 최대 L/D 비율 | 최대 속도 (RPM) | 모터 전력(kW) | 출력 (kg/hr) |

|---|---|---|---|---|---|

| RTM52C | 51.4 | 68 | 600 | 90 | 250-350 |

| RTM65C | 62.4 | 68 | 600 | 160 | 400-600 |

| RTM75C | 71.4 | 68 | 600 | 250 | 700-1000 |

| RTM85C | 81.0 | 68 | 600 | 280 | 800-1200 |

| RTM95C | 93.0 | 68 | 600 | 450 | 1300-2000 |

| RTM120C | 116.0 | 68 | 500 | 550 | 1500-2200 |

| RTM135C | 133.0 | 68 | 500 | 1200 | 3500-5000 |

우리가 다른 이유

| 특징 | 우리의 트윈 슈레드 컴포운딩 라인 | 일반적인 단 슈레드 혼합기 |

|---|---|---|

| 혼합 성능 | 고급 분산 및 분배 혼합 | 불일관된 혼합 |

| 과정 유연성 | 모듈식 슈레드 설계로 매우 높음 | 매우 낮음, 제한된 사용 |

| 자동 청소 | 최상의, 빠른 전환을 위해 우수 | 불량, 느리게 청소 |

| 발화물 제거 | 고급; 다단계 공기 배출을 지원 | 제한적이고 효율적이지 않음 |

고객님의 의견

“We installed the RTM75C for our glass-fiber reinforced nylon compounds. The modular screw allowed us to quickly optimize for different GF percentages. The consistency of our final product has been outstanding, helping us secure key contracts in the automotive sector.”

“We were impressed by the stability and automation of this machine. The time from startup to stable production is significantly shorter, and the PLC touchscreen is intuitive, which has lowered our operator training costs. It’s an investment that has clearly paid off.”

자주 묻는 질문

Our twin-screw line can process nearly all thermoplastics and their composites, including PE, PP, ABS, PC, PET, PA, PLA, TPE, and TPU, along with various fillers, reinforcements, and functional additives.

Absolutely. We provide comprehensive turnkey services. Our experienced engineers can manage on-site installation and commissioning and will provide systematic training for your operators and maintenance staff.

Simply fill out the form at the bottom of this page or contact our sales team directly. We will work with you to understand your specific application and provide a detailed quote for the optimal machine configuration.

폴리머 처리를 향상시키기 위해 준비되셨나요?

Contact our technical experts today. We will provide a tailored equipment solution and a detailed quote based on your specific formulations, throughput requirements, and budget.