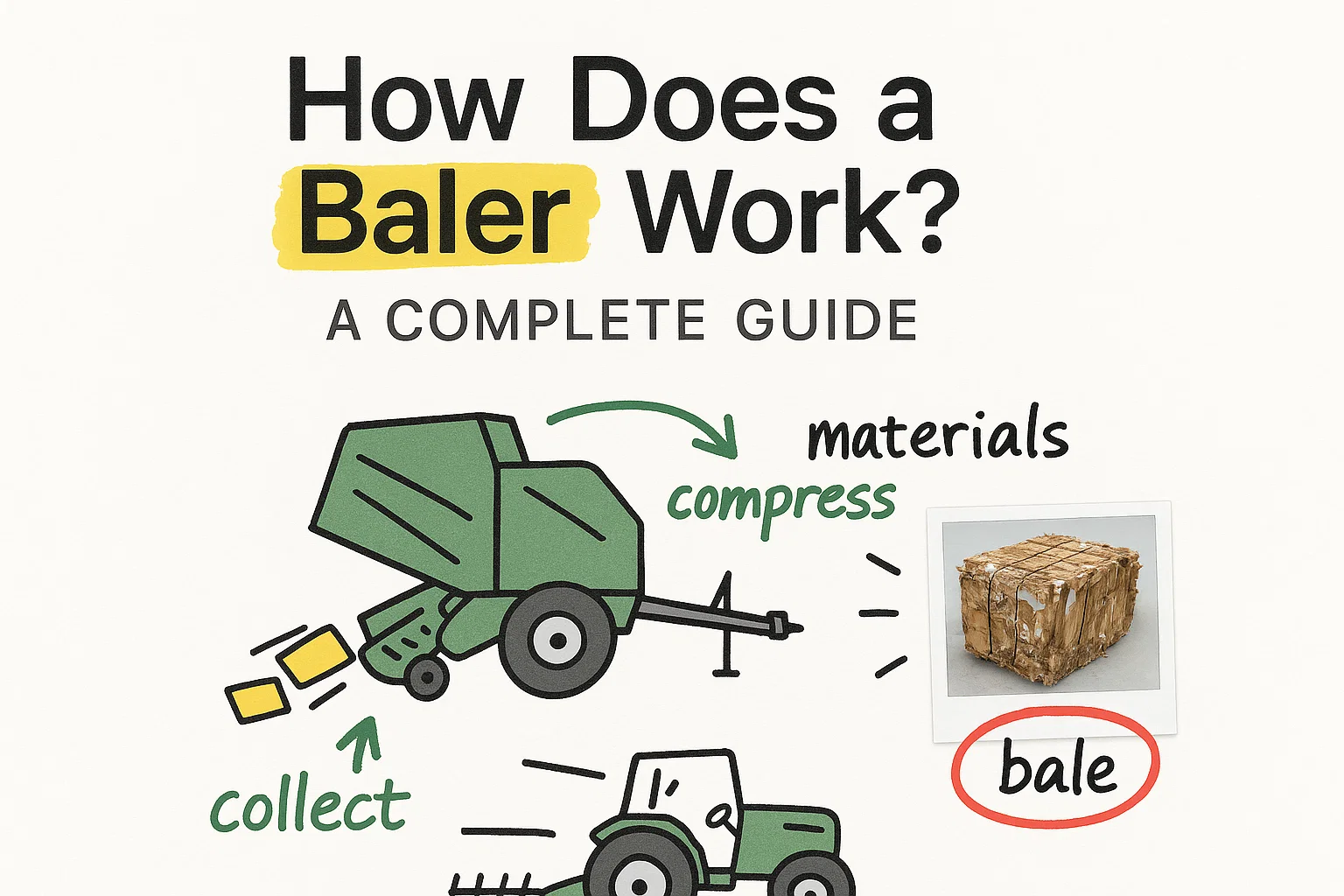

Balers make recycling operations cleaner, faster, and more profitable by turning loose, messy materials into dense, uniform bales. In a plastic recycling plant, a baler helps you control volume, cut transportation costs, and keep your sorting and washing areas organized—especially when you handle PET bottles, HDPE containers, PP woven bags, or plastic film. If you’re comparing equipment options, our リサイクルベーラー are built to match different materials, bale densities, and throughput targets.

Below is a clear, buyer-focused explanation of how a baler works, what happens in each step, and how to select the right baling machine for your facility.

What Is a Baler?

A baler (also called a 廃棄物圧縮機 または リサイクルベーラー) compresses loose material into a compact block and secures it using wire, PET strap, or other tying methods. You can bale:

- Plastics: PET bottles, HDPE/PP containers, rigid scrap, plastic film (LDPE/LLDPE), woven bags

- Paper & cardboard: OCC, mixed paper

- Other recyclables: aluminum cans, textiles (depending on model and configuration)

A baler doesn’t “recycle” material by itself—but it dramatically improves handling and logistics, which is where many recyclers lose money.

How a Baler Works: Step-by-Step (Recycling Applications)

1) Material Feeding

You feed loose recyclables into the baler chamber. Depending on throughput and automation level, feeding can be:

- Manual loading (common for small stations)

- Conveyor feeding (typical for MRFs and recycling lines)

- Hopper + automatic feeding (for continuous production)

Buyer tip: If you plan to bale light materials like film, you’ll usually need a properly designed hopper/conveyor and anti-bridging features to keep feeding stable.

2) Compression (The “Press” Stage)

The baler’s ram pushes material into a chamber using high force—most commonly from a hydraulic system. Hydraulic balers dominate recycling because they deliver:

- High compaction force

- Stable bale density

- Reliable operation for long shifts

Mechanical balers exist, but in recycling they are less common and typically less flexible.

3) Bale Forming and Density Build-Up

As the ram cycles, the chamber fills and density increases. Good bale quality depends on:

- Ram pressure + stroke design

- チャンバーサイズ

- Material type (PET bottles vs. film behaves very differently)

- Moisture and contamination level

Real-world note: Wet bottles or flakes can reduce bale stability and increase wire/strap stress. Plan your baling stage based on where it sits in your process (pre-wash vs. post-drying).

4) Tying / Binding (Securing the Bale)

Once the bale reaches target size/density, the baler ties it to hold shape during storage and transport. Common tying options:

- Wire ties (very common for cardboard and rigid plastics)

- PET straps (often used when wire isn’t preferred)

- Twine/net wrap (mostly agricultural, not typical for recycling balers)

5) Bale Ejection

After tying, the baler ejects the bale. Ejection can be:

- Manual eject (common for vertical balers)

- Semi-automatic or automatic eject (common for horizontal balers)

- Continuous operation with auto-tie (high-throughput plants)

Key Components Inside a Hydraulic Recycling Baler

- Hydraulic power unit: pump, motor, tank, valves

- Press ram & cylinder: creates compression force

- Bale chamber: where material is compacted

- Tying system: wire/strap channels, tying tools (manual or automatic)

- Control system: PLC + HMI (often includes safety interlocks)

- Safety system: emergency stops, door interlocks, guarding

A well-designed baler focuses on stable pressure, durable wear points, and safe access for maintenance—because downtime is usually more expensive than the machine.

Types of Balers (And When to Choose Each)

1) Vertical Balers

Best for: smaller recycling stations, warehouses, retail backrooms, low-to-mid volume.

- Compact footprint

- Lower investment cost

- Often manual feeding and manual/semi-auto tying

- Great for cardboard, soft plastics, and small-volume PET bottle baling

2) Horizontal Balers

Best for: high-volume recycling plants, MRFs, industrial scrap processors.

- Continuous feeding with conveyors

- Higher throughput and bale consistency

- Options for semi-auto or full auto-tie

- Ideal for plants that need predictable bale weight/density for buyers

3) Specialized / Application-Focused Balers

Depending on your material, you may need options like:

- Larger chamber size for bulky bottles

- Film-specific feeding/hopper design

- Reinforced chamber and wear parts for abrasive materials

Why Balers Matter in Plastic Recycling

Balers directly improve your operating costs and your sales efficiency:

- Reduce volume fast: cleaner floor, less mess, fewer handling steps

- Lower transport cost: dense bales maximize container and truck utilization

- Improve buyer acceptance: uniform bale size and stable density help downstream processors

- Support compliance & safety: organized storage reduces fire and trip risks

- Boost productivity: better logistics means your line runs smoother

How to Choose the Right Baler (Buyer Checklist)

Before you select a plastic recycling baler, confirm these parameters:

- Material type

- PET bottles? HDPE drums? PP woven bags? LDPE film?

- Throughput requirement

- How many kg/hour or tons/day must you bale?

- Bale size & target bale weight

- Often driven by your buyer’s specs and your transport method

- Desired bale density

- Density influences shipping cost and buyer acceptance

- Feeding method

- Manual vs conveyor vs hopper + automation

- Tying method

- Wire vs strap, manual vs automatic

- Utilities & installation

- Voltage, available space, ceiling height, forklift access

- Safety requirements

- Local standards, interlocks, guarding, training plan

If you share your material photos and capacity target, Rumtoo can recommend the correct baler type and configuration—not just a generic model.

Why Many Buyers Choose Rumtoo for Recycling Balers

Balers look similar online, but performance depends on design details and build quality. Rumtoo focuses on what keeps your plant profitable:

- Application-matched configuration: chamber size, feeding method, and tying setup based on your real material

- Heavy-duty structure for continuous work: stable compaction and long service life

- Clear operation and maintenance design: easier access, simpler daily checks, faster service

- End-to-end support: layout suggestion, integration with conveyors/sorting lines, and commissioning guidance

- Consistent build standards: reliable components and quality control before shipment

If you want, we can also suggest how to connect the baler with conveyors, sorting stations, or a full plastic recycling line.

よくある質問

Can a baler handle plastic film?

Yes, but film is light and “springy.” You typically need the right feeding/hopper design and enough compaction force to achieve stable bales.

Do I need a horizontal baler or vertical baler for PET bottles?

For low volumes, a vertical baler works. For continuous, high-volume PET bottle handling, a horizontal baler usually delivers better throughput and bale consistency.

What’s the biggest mistake when buying a baler?

Choosing based on price alone without matching the baler to your material behavior, feeding method, and target bale density. The wrong baler creates jams, unstable bales, and constant downtime.

Ready to Select the Right Baler?

Send Rumtoo these details and we’ll recommend the best baler configuration:

- Material photos (and contamination/moisture condition)

- Required capacity (kg/h or tons/day)

- Target bale size/weight (if your buyer specifies it)

- Voltage and available space

We’ll respond with a practical proposal that fits your recycling workflow—not a one-size-fits-all quote.