Vertical Mixing Machine for Plastic Granules

A high-efficiency vertical mixer designed for fast, uniform blending of plastic pellets, flakes, regrind, and additives. This model focuses on mixing only (no drying/heating function), making it a reliable auxiliary unit for extrusion, injection molding, and granulation lines.

Key Advantages

Built to achieve consistent mixing quality, reduce labor intensity, and simplify material handling in plastics processing.

- Fast, Uniform Mixing

Spiral lifting and centrifugal dispersion create a continuous circulation loop for thorough blending.

- Excellent Homogeneity

Improves batch-to-batch consistency—ideal for mixing additives, color masterbatch, and regrind.

- Stainless Steel Contact Parts

Corrosion-resistant barrel and blades help reduce contamination and make cleaning easier.

- Stable Operation

Optimized drive system supports reliable mixing performance for continuous production workflows.

- Compact & Mobile

Vertical structure saves floor space; casters make positioning and relocation convenient.

- Operator Safety

Safety interlocks and protective structures help reduce operational risk during use.

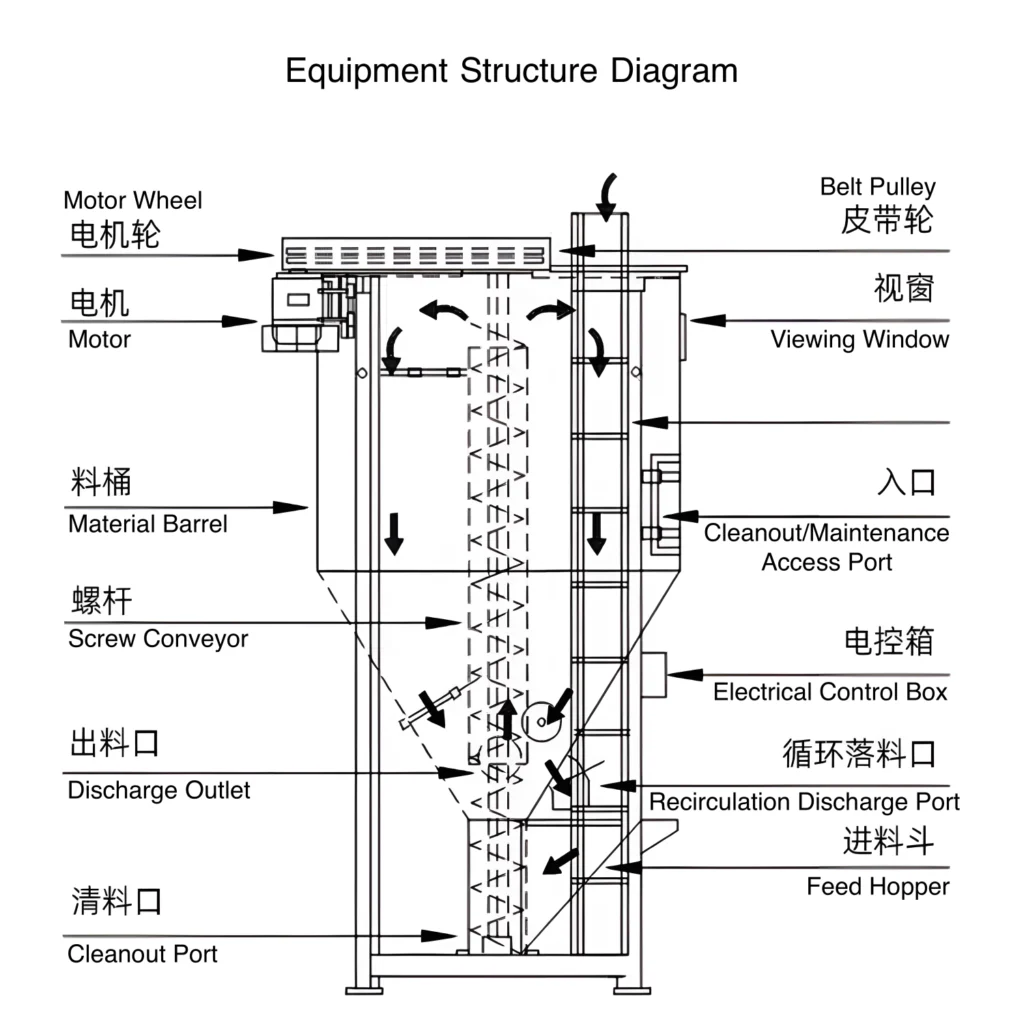

How It Works: Mixing in Three Steps

A simple workflow designed for efficient blending and smooth discharge into your next process.

- 1) Feeding

Load pellets/flakes/powders into the chamber—manual feeding or optional conveying can be configured.

- 2) Mixing

Spiral lifting moves material upward, then disperses it to form a continuous circulation loop for uniform blending.

- 3) Discharge

After reaching the desired mixing time, discharge through the outlet to bags, hoppers, or downstream equipment.

Technical Features

- Sealed, Clean Mixing

Enclosed mixing reduces dust and helps keep your workshop environment cleaner.

- Low-Noise Drive

Reducer-driven mixing supports durable operation with reduced noise.

- Robust Construction

Heavy-duty frame and reinforced structure improve stability and service life.

- Easy Cleaning

Stainless steel surfaces support fast cleaning, especially for frequent color changes.

- Simple Operation

Timer-based mixing control provides repeatable processing with minimal training.

- Convenient Discharge

Manual discharge valve supports controlled unloading with reduced material loss.

Operation & Maintenance

- Ensure mixing blades and fasteners are secure.

- Check the chamber for foreign objects.

- Verify the power supply matches the machine requirements.

- Run a short no-load test to confirm rotation direction.

Start the machine and run empty for 1–2 minutes. Add materials, set the mixing time on the timer, and allow the mixer to run until completion. Discharge through the outlet once mixing is finished.

Yes. The circulation mixing action is suitable for blending masterbatch, additives, and regrind. We can recommend batch size and mixing time based on your material density and additive ratio.

After powering off and disconnecting, clean all contact parts and remove residual material. Stainless steel surfaces help speed up cleaning for frequent color/material switches.

- Disconnect power before maintenance.

- Lubricate bearings regularly per your maintenance schedule.

- Inspect blades, fasteners, and electrical components periodically.

- Stop and troubleshoot immediately if abnormal noise or vibration occurs.

Selection depends on your batch size, target throughput, material bulk density, and feeding method. Share your material type and required capacity, and we’ll recommend a suitable configuration.

Warranty & Installation

- 1-Year Limited Warranty

All our recycling machinery comes with a limited warranty, ensuring peace of mind with your purchase.

- Installation Support

We provide installation guidance and can support commissioning and training. Customization is available based on your production needs.

Inquire Now

To get the latest prices and lead times, send us a message using the form below.