Vertical Debaler Machine for HDPE & PET Bales

Streamline your recycling infeed with our high-capacity Vertical Debaler Machine. Designed to handle large volumes of compacted HDPE and PET bottles, this powerful, automated solution breaks apart dense bales, reducing manual labor and dramatically increasing the productivity of your entire recycling line.

Key Advantages

- High-Capacity Infeed

Features a long conveyor belt capable of holding multiple bales at once, ensuring continuous, high-throughput operation.

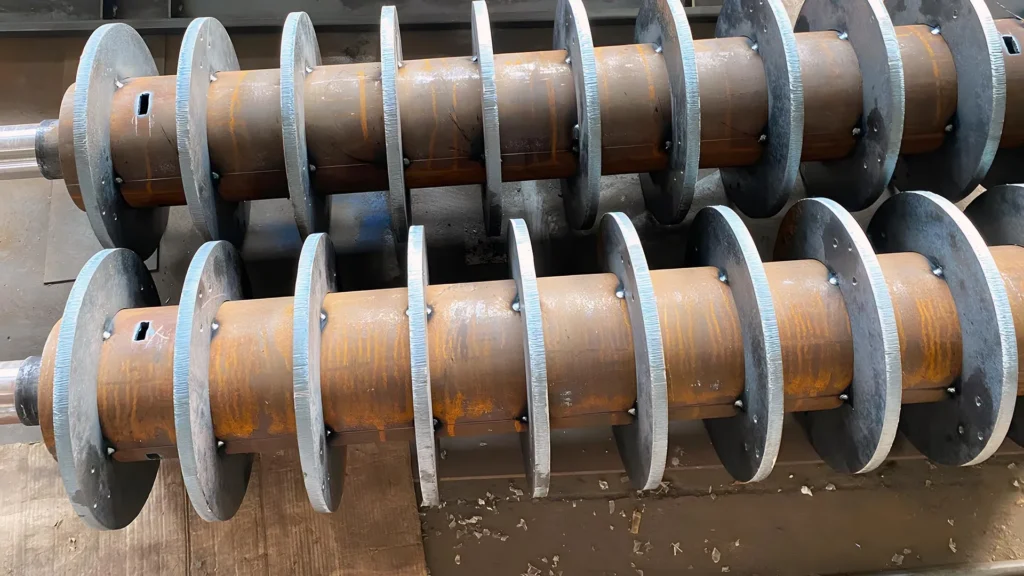

- Powerful Dual-Rotor System

Two opposite-rotating vertical rotors with scattering disks efficiently tear apart even the most densely compacted bales.

- Reduces Manual Labor

Automates the bale breaking process, significantly reducing operational costs and freeing up staff for other tasks.

- Boosts Line Productivity

Creates a steady, consistent flow of loosened material, maximizing the efficiency of your entire recycling plant.

- Simple & Efficient Design

A straightforward and robust mechanical process ensures high reliability and ease of use in demanding industrial environments.

- Customizable Power

Larger and more powerful models are available to handle various bale sizes and specific production requirements.

How It Works: A Step-by-Step Process

- 1Bale Loading

Multiple bales are loaded onto the long infeed conveyor belt with a forklift, creating a buffer for continuous operation.

- 2Wire Removal

As the bales move forward, the binding wires or straps are manually cut and removed before they enter the machine.

- 3Vertical Debaling

The bale enters the chamber where two powerful, counter-rotating rotors aggressively loosen and scatter the plastic.

- 4Material Discharge

The now-loose plastic bottles fall onto a lower discharge conveyor, ready for the next processing stage.

Technical Specifications

- Main Motor Power

7.5 kW x 2

- Feeder Dimensions

1550mm x 1850mm

- CE Certification

Available upon request to meet international safety and quality standards.

- Material Suitability

Ideal for rigid plastics like HDPE and PET bottles. Not suitable for plastic film.

Frequently Asked Questions

Our vertical debaler is designed for higher throughput, featuring a long infeed conveyor to queue multiple bales. Its two vertical, counter-rotating rotors provide a very effective method for breaking apart dense bales of rigid plastics like PET and HDPE bottles.

The machine automates the most difficult part—the physical breaking of the bale. However, it still requires an operator to load the bales onto the conveyor with a forklift and to manually cut the binding wires before the bales enter the debaling chamber.

No, this machine is specifically designed for rigid plastics. Using it for plastic film can cause the film to wrap around the rotors, leading to machine damage. For plastic film, we recommend a single-shaft plastic shredder.

Warranty & Installation

- 1-Year Limited Warranty

All our recycling machinery comes with a limited warranty, ensuring peace of mind with your purchase.

- Expert Installation Support

We offer installation packages where our engineers can travel to your facility to guide you through the setup process. All our products can be customized to customer requirements.

Inquire Now

To get the latest prices and lead times, send us a message using the form below.