: Inline metal detectors and optical sorters scan for ferrous/non-ferrous metals or color anomalies, ejecting rejects with precision. This safeguards flake integrity for sensitive end-uses. transform post-consumer waste into valuable resources at an unprecedented scale. With billions of plastic bottles entering the waste stream annually, efficient recycling technology is key to reducing landfill waste, conserving resources, and curbing plastic pollution. A properly designed PET bottle recycling line processes used bottles, complete with caps and labels, into pristine, reusable flakes with exceptional purity, minimal moisture, and uniform quality for high-value applications like new bottle production, textile fibers, and packaging materials.

Whether you’re a recycling facility manager, sustainability coordinator, or entrepreneur exploring eco-friendly ventures, understanding how PET bottle recycling lines operate empowers informed decision-making. This guide breaks down the working process, spotlights key components, explores output capacities, and highlights real-world benefits. Let’s explore how this technology turns waste into worth.

%%

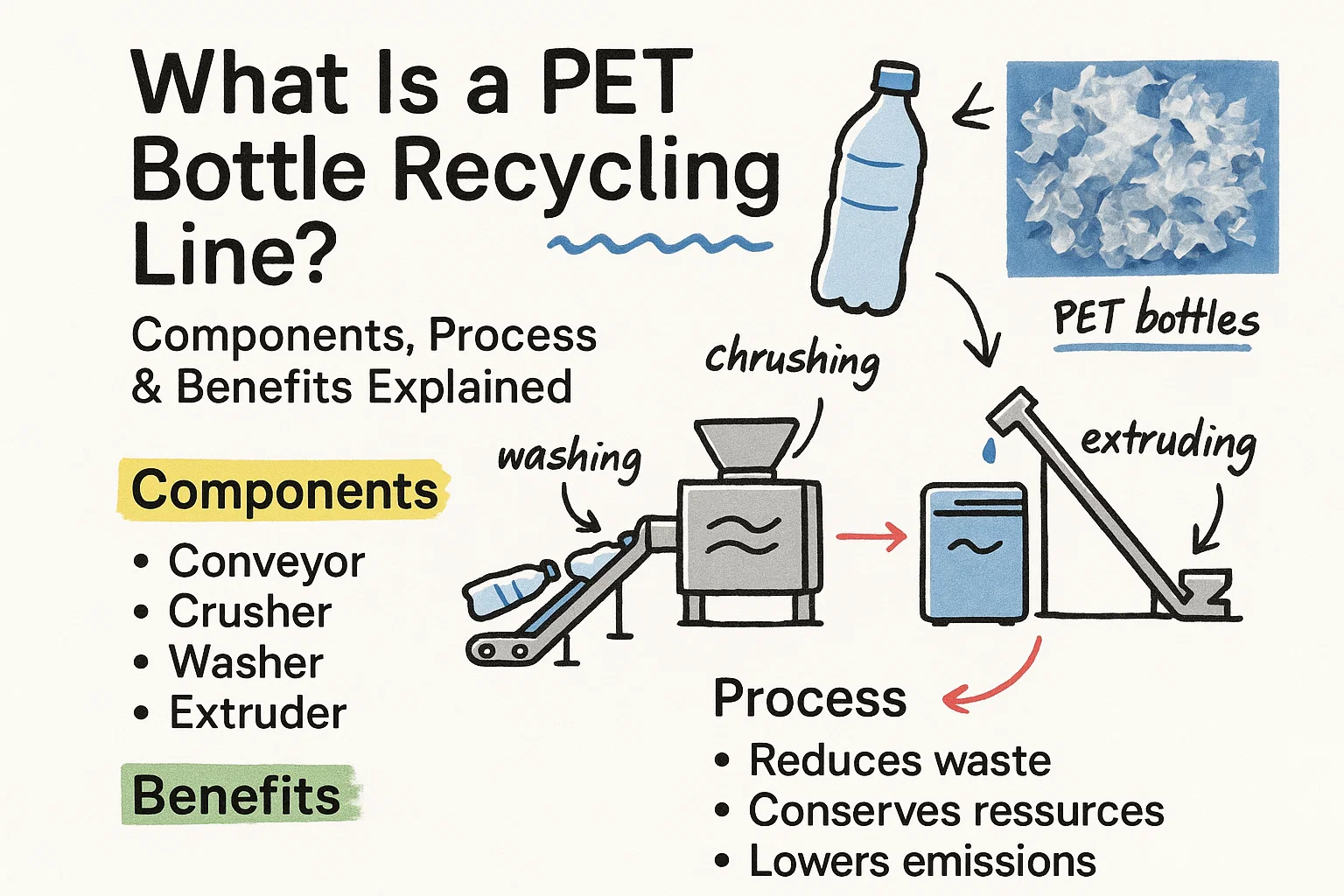

A %% is an integrated processing system designed for high-volume handling of used PET bottles from diverse sources like household collections, commercial drop-offs, or municipal waste streams. Unlike basic sorting setups, this line handles the full lifecycle of a bottle, from initial breakdown to final flake production, ensuring maximum material recovery.

Why invest in one? Beyond compliance with environmental regulations, a well-designed PET bottle recycling line delivers tangible ROI:

- Kaynak Kurtarma: Recovers up to 95% of PET material, reducing raw virgin plastic needs

- Maliyet Tasarrufu: Lowers operational expenses through automated efficiency and reduced energy consumption

- At its core, a: Produces food-grade flakes that command premium prices in the circular economy

- Çevresel Etki: Cuts CO2 emissions by up to 70% compared to virgin PET production, supporting global sustainability goals

Common questions like “How does a PET bottle recycling line improve sustainability?” or “What are the benefits of investing in PET recycling equipment?” lead operators to evaluate these systems. The answer lies in streamlined processing, minimized contamination, and maximized output that makes recycling both viable and profitable.

Interested in plastic bottle recycling solutions? Keep reading to see how this technology fits your operation.

%%

A %% operates as a coordinated system of interconnected stages that methodically purify and prepare PET for reuse. From unpacking baled bottles to drying flawless flakes, each phase builds on the previous one for end-to-end efficiency. Here’s the logical flow:

1. Unpacking and Initial Sorting

Compressed bales arrive and feed into an unpacking machine that gently disentangles bottles to prevent damage. Basic sorting removes non-PET contaminants like glass or paper, establishing a clean foundation for processing.

2. Pre-Washing

Bottles enter a pre-wash unit where high-pressure hot water blasts away loose dirt, residues, and initial debris. This step often uses recycled water loops to prevent downstream clogs and boost overall hygiene while reducing water consumption.

3. Label and Cap Separation

A specialized label removal machine employs air jets, steam, or mechanical peeling to strip away adhesives and PVC labels. Caps (typically polypropylene) separate via density-based flotation tanks, allowing full material segregation for higher purity levels.

4. Size Reduction Through Granulating

Whole bottles meet a heavy-duty granulator or shredder that chops them into uniform flakes while incorporating a preliminary rinse. This reduces volume by up to 80%, making subsequent cleaning faster and more effective.

5. Intensive Cleaning With Friction and Hot Washing

Flakes tumble through high-speed friction washers where rotating blades and sprays scrub away stubborn inks, oils, and glues. Next comes the hot wash tank infused with caustic soda (sodium hydroxide) and steam. This combination eliminates over 99% of impurities, including proteins and hydrocarbons.

6. Decontamination and Detection

Inline metal detectors and optical sorters scan for ferrous and non-ferrous metals or color anomalies, ejecting rejects with precision. This safeguards flake integrity for sensitive end-uses.

7. Dehydration, Secondary Granulation, and Drying

Excess water flings off in centrifugal dryers, followed by a second granulation pass for size consistency. Finally, thermal dryers reduce moisture to below 0.5%, yielding dry, baggable flakes ready for extrusion or sale.

Related searches like “steps in PET bottle recycling process” or “how to remove labels from PET bottles efficiently” highlight curiosity around these mechanics. By addressing them directly, facilities can troubleshoot common challenges such as inconsistent flake quality or high water usage.

, keep reading to see how it fits your operation.

%% %% thrives on its modular components, each designed for reliability and scalability. This list provides practical insights to help you evaluate setups, including energy ratings, maintenance needs, and integration ease:

| %% | İşlev | isn’t a single machine—it’s a symphony of interconnected stages that methodically purify and prepare PET for rebirth. From unpacking baled bottles to drying flawless flakes, each phase builds on the last, ensuring end-to-end efficiency. Here’s a logical flow of the process: |

|---|---|---|

| %% | Loosens and feeds baled bottles without crushing | Pair with conveyor belts for smooth throughput; handles 1-5 ton bales efficiently |

| : Compressed bales arrive and are fed into an unpacking machine, which gently disentangles bottles to prevent damage. Basic sorting removes non-PET contaminants like glass or paper, setting a clean foundation. | Initial hot-water rinse to dissolve surface contaminants | Use eco-friendly detergents to cut chemical costs by 20% |

| Etiket Sökme Makinası | Peels or dissolves labels using steam or abrasion | Monitor adhesive buildup; regular blade sharpening extends life by 50% |

| %% | Identifies and diverts metallic impurities post-shredding | Calibrate for bottle cap fragments; integrates with auto-eject systems |

| Granülatör/Parçalayıcı | Shreds bottles into flakes with built-in pre-rinse | Choose rotor styles based on bottle thickness; hardened steel offers durability |

| Yüksek Hızlı Sürtünme Yıkayıcı | Scrubs flakes via mechanical agitation and water jets | Adjust speeds for flake size; reduce energy by recycling wash water |

| Intensive Cleaning (Friction and Hot Washing) | Deep-cleans with alkaline solutions at 80-90°C to break down oils and glue | pH monitoring prevents over-alkalinity, ensuring flake neutrality |

| Santrifüj Kurutucu | Removes excess water through high-speed spinning | Variable-frequency drives optimize energy use by up to 15% |

| Termal Kurutucu | Final moisture reduction to below 0.5% for storage stability | Temperature controls prevent flake degradation while ensuring thorough drying |

These elements, often customizable, ensure your line achieves IV (Intrinsic Viscosity) values above 0.75, which is crucial for premium rPET (recycled PET) grades. Wondering “What equipment is needed for PET recycling?” This lineup covers everything from entry-level to industrial-scale operations.

Decontamination and Detection

No two recycling operations are identical, which is why : Inline metal detectors and optical sorters scan for ferrous/non-ferrous metals or color anomalies, ejecting rejects with precision. This safeguards flake integrity for sensitive end-uses. offer versatile capacities to match your volume requirements. Typical outputs include:

- 500-600 kg/h: Perfect for startups or pilot projects testing small-scale recycling concepts

- %%: Suited for mid-sized facilities handling regional collections

- : Bölgesel toplanımları işleyen orta ölçekli tesisler için uygundur.: Balances efficiency for growing urban recyclers

- 1,000-1,500 kg/h: High-demand setups for commercial processors

- %%: Enterprise-level for large-volume operators

- : Ticari işleyiciler için yüksek talepli kurulumlar.: Industrial systems processing municipal waste streams

Factors like feedstock quality, energy supply, and automation level influence these rates. For instance, upgrading to variable-frequency drives can boost efficiency by 15%. Long-tail queries such as “What is the capacity of a PET washing line for 1000 kg per hour?” or “Scalable PET recycling solutions for businesses” point to the need for modular designs that expand today and scale tomorrow.

: Büyük hacim işleyiciler için kurumsal seviyede.

Bir yatırıma yatırım yapmak %% goes beyond machinery. It fosters a greener tomorrow while driving bottom-line growth. Facilities using these systems report 30-50% higher flake recovery rates, faster payback periods (often under 2 years), and compliance with standards like FDA or EFSA for food-contact materials. In a market projected to hit $15 billion by 2030, early adopters gain a competitive edge.

Understanding the full scope of PET bottle recycling processes helps you make informed equipment decisions. From initial sorting to final flake production, each stage contributes to overall system efficiency and output quality.

Curious about specifics like PET recycling machine costs or maintenance tips for washing lines? Our experts provide guidance on:

- Custom capacity planning for your facility

- Energy-efficient upgrades to reduce operating costs

- Güçlendirme takvimleri, en yüksek çalışma süresi için

- %%

Gıda sınıfı parçacık üretimi için kalite kontrol protokolleri PET Şişe Geri Dönüşüm Sistemi %% Rumtoo Makinesi, Recycling operasyonunuzu dönüştürmeye hazır mısınız? En son teknoloji ürünü çözümlerimizi keşfedin.