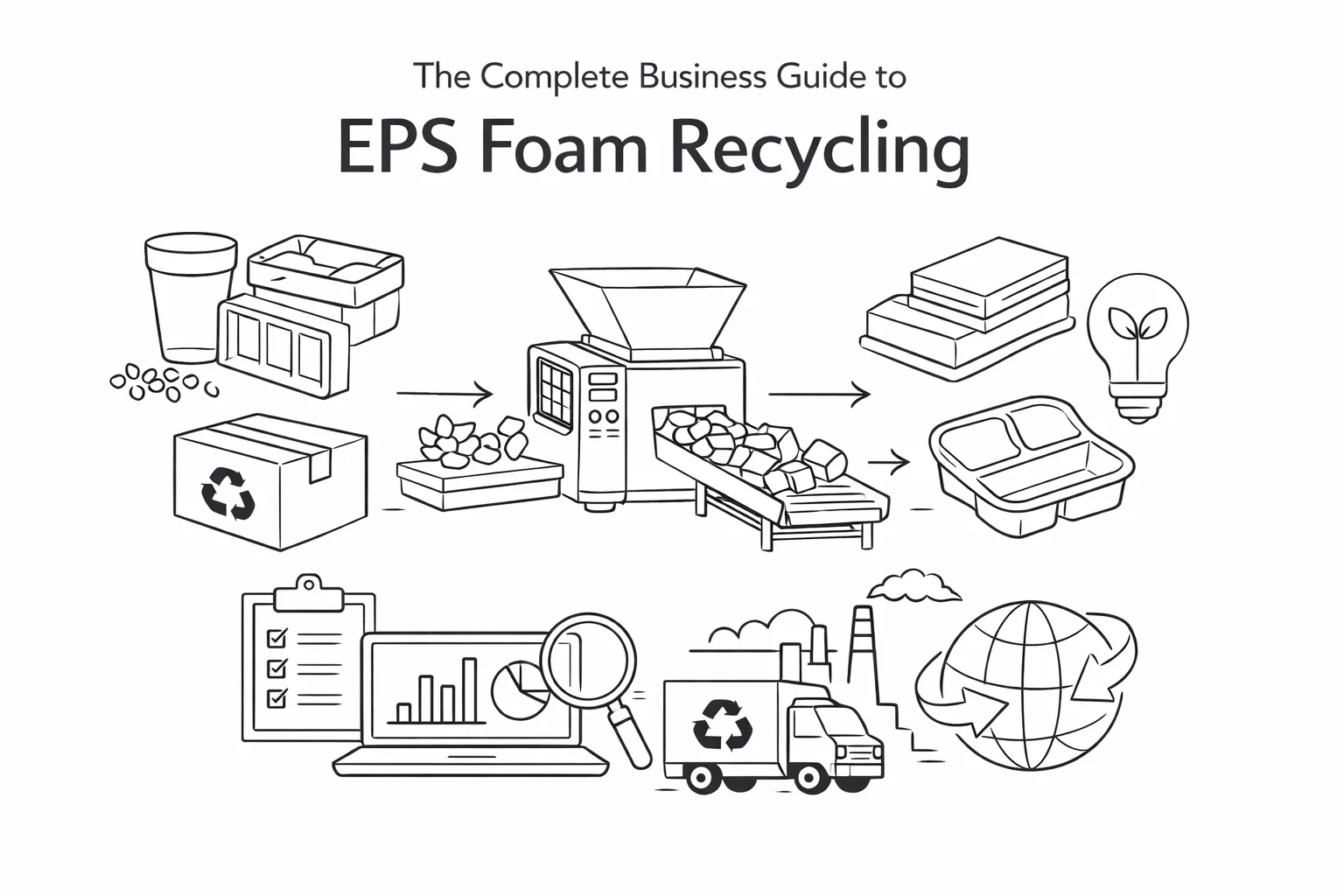

EPS foam recycling transforms bulky packaging waste into profitable recycled material. Businesses generating consistent foam waste can cut disposal costs by 60-80% while creating new revenue streams through densified blocks that sell for $0.10-0.30 per pound.[1]

The challenge is clear. EPS contains 98% air, making transportation expensive and storage impractical. A single truckload of loose foam compresses into just one pallet of blocks.[1] For manufacturers, distributors, and recyclers handling 500+ kg of foam monthly, this volume creates both a cost burden and an environmental liability.

Why EPS Recycling Makes Business Sense

Material costs drive the economics. Landfill tipping fees range from $80-120 per ton in most regions. A mid-size operation generating 500 kg daily of EPS scrap recovers equipment investment within 12-18 months through avoided disposal fees alone.[1]

Revenue adds to savings. Recycled EPS blocks command market prices between $0.10-0.30 per pound from reclaimers who pelletize material for picture frames, building products, and industrial packaging.[2] What was a disposal cost becomes an income source.

Regulatory pressure accelerates adoption. The global EPS recycling rate reached approximately 15% in 2022, according to the American Chemistry Council, with infrastructure expanding in regions with established waste management systems.[3] Companies face mounting requirements to demonstrate waste reduction and circular economy practices.

Core Recycling Technologies

Cold Compression

Mechanical compactors crush foam into dense blocks through hydraulic pressure, achieving 50:1 volume reduction ratios. This method requires no heat, produces no emissions, and works well for facilities with space constraints or outdoor operations.[1] EPS foam cold press machines integrate shredding and compression systems to process 80-150 kg/hour with minimal energy consumption.

Hot Melting

Thermal densifiers heat shredded foam to melting point, then extrude it into ingots. Volume reduction reaches 90:1, creating denser blocks that command higher prices. The process requires controlled heating chambers and adequate ventilation.[1]

Peletizare

Direct pelletizing converts loose foam into plastic pellets without pre-compression. This single-step process appeals to operations seeking simplified workflows, though equipment costs run higher than basic compactors.[2] EPS foam pelletizing machines use hot-melt extrusion technology to produce uniform pellets ready for remanufacturing into new products.

Industries With High ROI Potential

Furniture manufacturers and retailers handle protective foam for every shipped item. Electronics distributors unpack appliances from molded EPS daily. Food service operations manage insulated shipping containers. Construction sites generate cutoffs from insulation panels.[3]

Fish markets present a specific case. Sydney Fish Market in Australia installed industrial shredders with government subsidies to process insulation boxes, producing high-density blocks exported to Southeast Asia for plastic products.[5] Similar operations serve seafood distribution networks globally.

Getting Started: Equipment Selection

Throughput capacity determines appropriate equipment. Operations processing under 200 kg daily can start with compact units rated for 100-200 kg/hour. Facilities handling 500+ kg daily require industrial-grade systems with automatic feeding and continuous operation capability.

Material type matters. White EPS packaging differs from colored foam or extruded polystyrene (XPS). Contaminated material requires pre-sorting. Equipment designed for mixed streams costs more but handles varied inputs.[6]

Space and power constraints shape choices. Cold compression units need less power and can operate outdoors. Hot melting systems require dedicated indoor space with proper ventilation and three-phase electrical service.

Collection and Handling Best Practices

Source separation prevents contamination. White packaging foam should not mix with colored foam, food-contact material, or non-foam plastics. Tape, labels, and cardboard must be removed before processing.

Storage presents challenges due to volume. Designate a specific receiving area with weather protection. Loose foam attracts pests and creates fire hazards when accumulated in large quantities.

Processing schedules affect efficiency. Batch processing once or twice weekly suits operations with moderate volumes. High-volume facilities benefit from continuous processing with dedicated staff.

Market Outlets for Recycled Material

Direct buyers include foam product manufacturers who reuse material in non-food applications. Frame manufacturers incorporate recycled EPS into decorative molding. Construction product makers use it in concrete forms and insulation backing.[3]

Recycling brokers aggregate material from multiple sources, providing pickup services and guaranteed pricing. This option works best for facilities producing 2-5 tons monthly of consistent-quality blocks.

Regional collection networks operate in some areas. The Foam Recycling Coalition supports densifier grants in 31 US cities, providing access to 12.4 million people.[7] Participation in these programs can offset equipment costs and guarantee material outlets.

Financial Planning and Payback

A cold compression system processing 300 kg daily costs approximately $25,000-40,000. With tipping fees of $100/ton and material sales of $0.20/pound, payback typically occurs in 18-24 months.

Hot melting equipment requires $40,000-70,000 investment but produces denser blocks commanding premium pricing. Higher throughput operations achieve 12-18 month payback periods.

Operating costs include electricity (typically $0.50-1.50 per processing hour), maintenance (5-8% of equipment cost annually), and labor. Many facilities operate equipment with existing staff during normal work hours.

Common Implementation Mistakes

Undersized equipment creates bottlenecks. A system rated for 100 kg/hour cannot handle 500 kg daily production within a normal work shift when accounting for loading time and block changes.

Inadequate material preparation slows processing. Contaminated foam damages equipment and reduces block quality. Failed blocks cannot be sold, turning potential revenue into waste.

Lack of buyer agreements before equipment purchase leaves operators with compressed material but no outlet. Establish buyer relationships and pricing before investing in processing equipment.

Beneficii pentru mediu și sustenabilitate

EPS persists in the environment for 500+ years. Recycling keeps petroleum-based polymers out of landfills and waterways where they fragment into microplastics.[1] Material recycling reduces demand for virgin polystyrene production.

Carbon footprint reduction comes from avoided transportation. Densification cuts shipping volumes by 90-95%, reducing fuel consumption and emissions from waste hauling.

Closed-loop systems provide the highest environmental value. Manufacturers who reclaim production scrap and return it to their own process achieve near-zero waste while cutting raw material costs by 5-15%.[1]

Next Steps for Your Operation

Audit current foam waste generation over 30 days. Track volumes, types, and contamination levels. This data determines appropriate equipment capacity and helps calculate ROI.

Research local buyers and recycling networks. Contact frame manufacturers, construction product makers, and recycling brokers within 200 miles. Verify pricing and volume requirements.

Evaluate equipment options from established manufacturers. Review cold press compactors for mechanical compression or pelletizing systems for direct-to-pellet processing. Request throughput guarantees, block density specifications, and warranty terms. Compare operating costs including power consumption and maintenance requirements.

Consider starting with equipment grants or shared-use programs if available in your region. The Foam Recycling Coalition and state environmental programs offer funding that can offset 25-50% of equipment costs.[7]

For businesses committed to waste reduction and operational efficiency, EPS recycling offers clear economic and environmental returns. The technology is proven, markets exist for recycled material, and payback periods typically fall within standard capital equipment timelines. Visit Rumtoo to explore processing equipment options suited to your operation.