In the plastic recycling industry, Rigid PVC (Polyvinyl Chloride) is notorious. While it is a highly valuable material to recover—widely used in construction pipes, window profiles, and siding—it is also one of the most difficult to process safely.

Unlike softer plastics like PE or PP, rigid PVC is brittle. When crushed, it doesn’t just cut; it shatters. This characteristic creates two major operational hazards: excessive fine dust and extreme impact noise.

For plant managers and buyers, these aren’t just annoyances—they are liability issues involving OSHA compliance, worker safety, and material quality. This guide details professional strategies to control these hazards, focusing on modern equipment engineering.

1. The Dust Challenge: Why PVC Fines Are Dangerous

When rigid PVC pipes are granulated, they generate a significant amount of “fines” (micro-particles). Unlike general plastic dust, PVC dust poses specific risks:

- Health Hazards: According to industry safety studies, prolonged inhalation of PVC particulates can lead to chronic respiratory issues. Furthermore, additives often found in PVC formulations can be harmful if airborne controls are not in place.

- Equipment Damage: PVC dust is abrasive and static-prone. It infiltrates motor bearings and electrical panels, causing premature equipment failure.

- Explosion Risks: While less volatile than some organic dusts, high concentrations of suspended plastic dust can still pose a combustion risk in enclosed spaces.

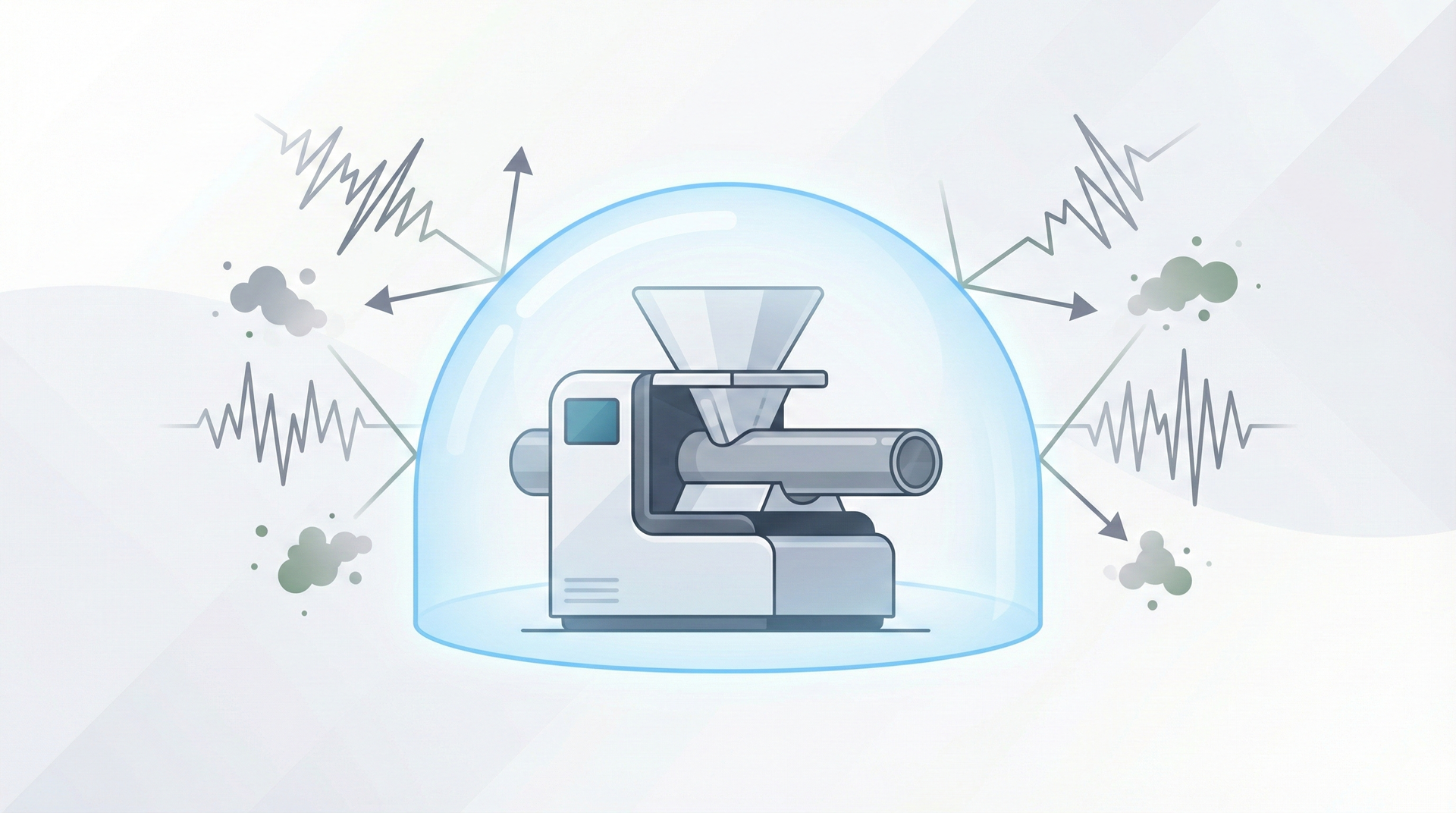

The Engineering Solution: Negative Pressure & Sealing

To mitigate these risks, rely on a multi-tiered defense system rather than simple ventilation.

- Closed-Loop Cyclone Separation: Never rely on a simple gravity discharge into a bin. Use a cyclone separator with a rotary valve. This uses centrifugal force to separate the regrind from the air, allowing the heavy plastic to fall while air is drawn up.

- Pulse-Jet Dust Collectors: For the remaining airborne fines, a bag filtration system with pulse-jet cleaning is essential. This actively filters the air exhaust, capturing particles as small as 1–5 microns.

- External Bearing Design: When selecting a crusher, look for externally mounted bearings. By isolating the bearings from the cutting chamber, you prevent dust from entering the grease and seizing the rotor—a standard feature on high-end units like the Rumtoo Horizontal Crusher.

2. The Noise Challenge: Managing Decibels (dB)

Crushing hollow, rigid PVC pipes is arguably the loudest process in a recycling plant. A standard vertical hopper granulator can easily exceed 105–110 dB(A).

OSHA Regulations (29 CFR 1910.95) stipulate that exposure to noise levels of 90 dB is limited to 8 hours, while 105 dB is permissible for only 1 hour. Exceeding these limits without protection requires a Hearing Conservation Program and can lead to hefty fines.

Strategies for Noise Reduction

- V-Cut Rotor Geometry: Avoid flat blades. A “V” or “Chevron” rotor design creates a scissor-like cut (shear) rather than a high-impact chop. This requires less energy and significantly reduces noise generation at the source.

- Soundproof Enclosures: High-quality crushers feature a double-walled hopper filled with sound-dampening foam. This typically reduces noise pollution by 10–15 dB.

- Vibration Isolation: Ensure the machine sits on heavy-duty shock absorbers to prevent structural vibration from turning your facility’s concrete floor into a giant speaker.

3. The “Horizontal” Advantage: A Game Changer for PVC Pipes

The most effective way to control dust and noise isn’t just about adding filters or foam—it’s about changing how you feed the material. This is where Horizontal Crushers outperform traditional vertical granulators.

The Problem with Vertical Feeding

In a standard vertical granulator, you must cut long pipes into short sections to fit them in the hopper.

- Noise: The pieces bounce violently against the rotor and chamber walls (“fly-back”), creating a deafening racket.

- Dust: The bouncing action pulverizes the plastic before it is cut, creating excess fines.

- Safety: The open hopper can allow material to fly back out toward the operator.

The Rumtoo Horizontal Solution

Machines like the Rumtoo Horizontal Crusher for PVC Pipe and Profiles solve these problems via geometry:

- No Pre-Cutting Required: You can feed whole 3-meter or 6-meter pipes directly into the horizontal trough. This eliminates the labor and noise of pre-cutting with saws.

- Controlled Feeding: The horizontal trough aligns the pipe perfectly with the rotor. The pipe does not bounce; it is drawn in smoothly. This stability drastically reduces impact noise.

- Dust Containment: Because the hopper is a long, enclosed horizontal chute, fly-back is virtually eliminated. Dust is generated only at the cutting face, where the extraction system can immediately capture it.

4. Operational Best Practices for Buyers

If you are upgrading your PVC recycling line, use this checklist to ensure you are buying a system that handles dust and noise professionally:

- Check the Rotor Speed: For rigid PVC, lower RPM with higher torque is preferred. It generates less dust (“fines”) and noise than high-speed granulation.

- Blade Maintenance is Key: Dull blades shatter PVC rather than cutting it. This shattering creates dust. Ensure your machine has easy access for blade changes to encourage regular maintenance.

- Ask for Decibel Ratings: Reputable manufacturers should provide dB ratings for their machines under load.

- Prioritize Integration: Ensure your crusher can integrate seamlessly with an air-conveying system to move material to the next stage (silo or extruder) without manual handling, keeping the dust contained.

Conclusion

Controlling dust and noise in rigid PVC recycling is not just about compliance; it is about efficiency. A cleaner plant protects your workers, reduces machine downtime, and produces higher-quality regrind.

For facilities processing long pipes and profiles, the Horizontal Crusher is the superior technological choice. It attacks the problem at the source—eliminating the bounce, the pre-cutting, and the exposure risks associated with vertical hoppers.

Ready to upgrade your facility’s safety and efficiency?

Explore the specifications of our Horizontal Crusher for PVC Pipe and Profiles and see how Rumtoo engineering can transform your recycling line.