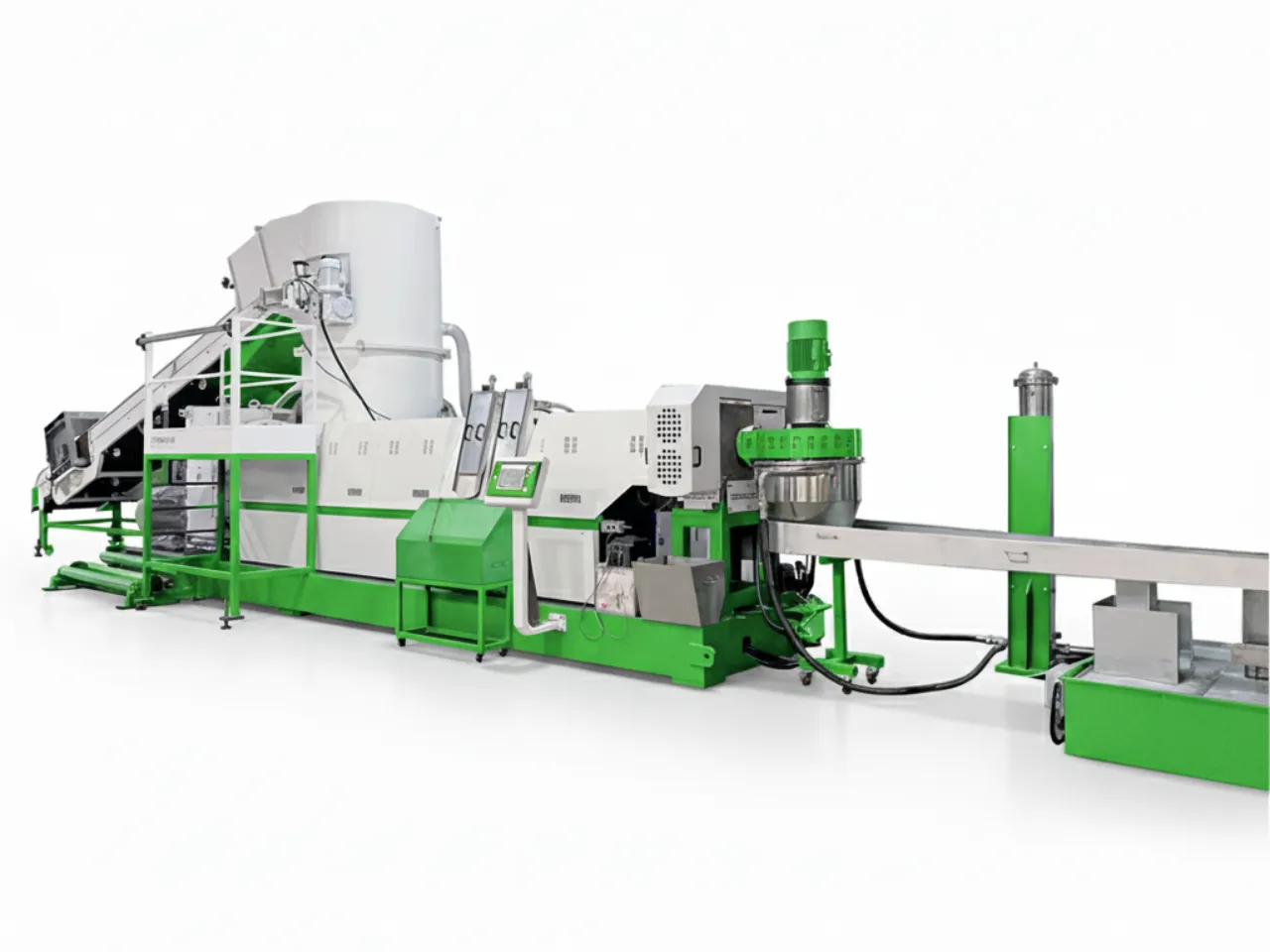

Revolutionizing Waste Management: MSW Sorting Line

Introduction In an era where environmental sustainability is paramount, managing Municipal Solid Waste (MSW) effectively has become a global priority. MSW sorting lines stand at the forefront of this environmental endeavor, transf...