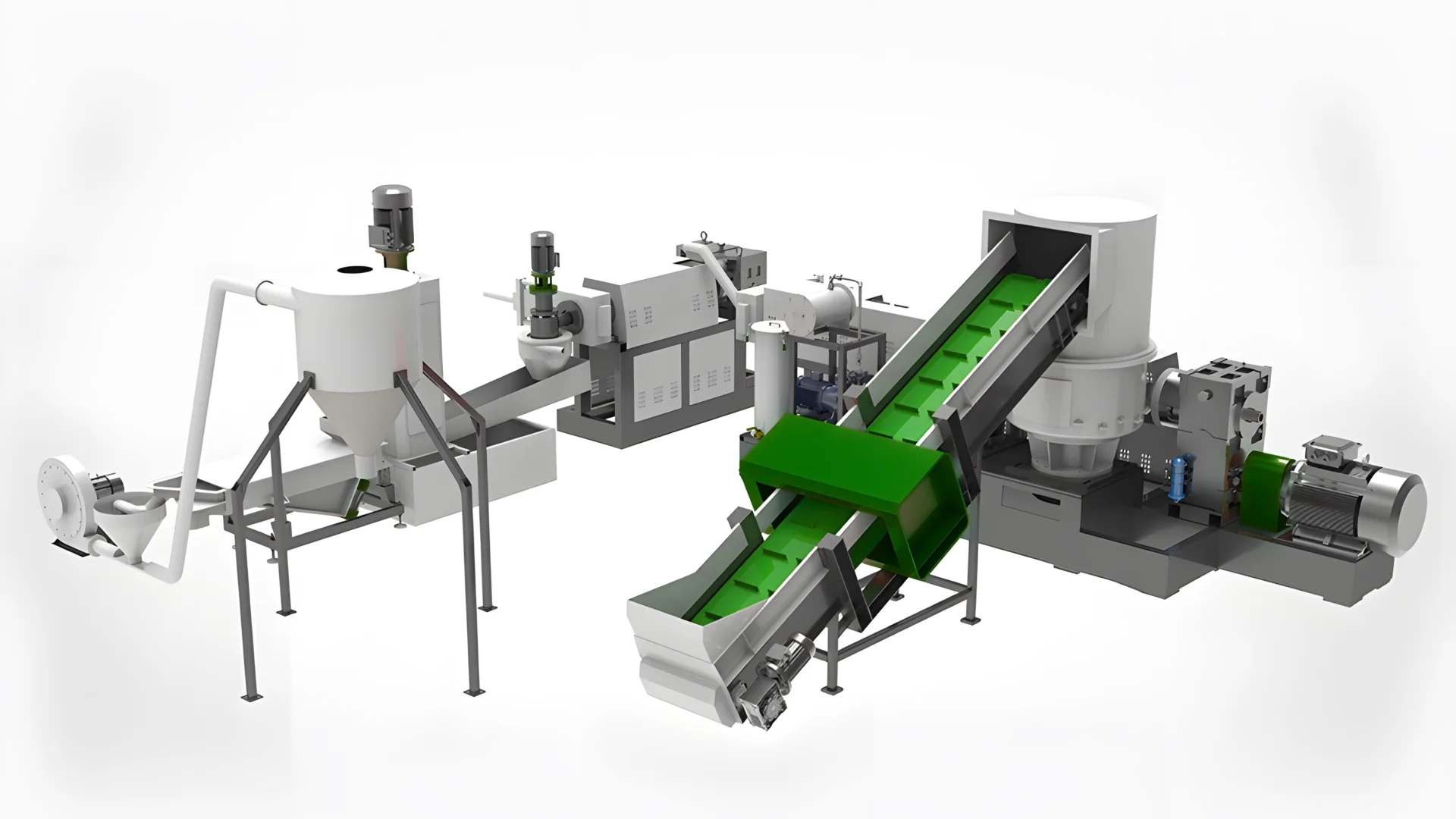

Compactador de cortador Recycling Pelletizing Line

Looking for a sustainable solution to manage your plastic waste? Rumtoo Machinery's Cutter Compactor line offers a highly efficient and cost-effective way to transform a wide range of plastic scraps into valuable pellets.

Processamento de Resíduos de Plástico com Versatilidade

This innovative system is designed to handle a diverse range of plastic materials, including:

- Filmes

PP, PE, HDPE, LDPE, LLDPE

- Embalagem

PA66, PC, PET, OPP, BOPET

- Fibras e Outros

ABS, Raffia, Seda, Fio, PE Espumado

Do Resíduo ao Grânulo: Um Processo Simplificado

- 1. Alimentação

A belt conveyor, with an optional metal detector, transports plastic scraps into the compactor.

- 2. Compactação

Rotating blades cut, compact, and soften the material using frictional heat, ensuring stable feeding into the extruder.

- 3. Extrusão

A single-screw extruder gently melts the material. A double-zone vacuum degassing system removes volatiles for high-quality output.

- 4. Pelotização

Water-ring die-face cutting technology precisely cuts the extruded material into uniform pellets.

- 5. Secagem

An advanced dewatering sieve and centrifugal system efficiently dry the pellets, minimizing energy consumption.

Principais benefícios

- Alta eficiência

Process a wide range of plastic materials with high output rates (180-1500 kg/h depending on the model).

- Custo-benefício

Reduza os custos de mão de obra e o consumo de energia através de processos automatizados e secagem eficiente.

- Sustentabilidade

Transformar resíduos plásticos em recursos valiosos, contribuindo para uma economia circular.

- Costumização

A Rumtoo oferece soluções customizadas para atender às suas necessidades e requisitos de materiais específicos.

Especificações técnicas

| Modelo | Produção (kg/h) |

|---|---|

| GL85 | 180-250 |

| GL100 | 300-400 |

| GL130 | 500-600 |

| GL160 | 700-800 |

| GL180 | 1000-1500 |

*Note: Output capacity may vary depending on material type and motor configuration. Please contact Rumtoo for a personalized quotation.

perguntas frequentes

The main advantage is its ability to handle lightweight, fluffy materials like films and fibers in a single, integrated step. The compactor pre-densifies and pre-heats the material, which allows for a very stable and efficient feeding process into the extruder, something that is difficult to achieve with a standard feeding hopper.

For most soft materials like films and light scraps, a separate shredder is not needed. The cutter compactor itself performs the initial size reduction and densification. However, for very large or thick materials, a pre-shredder might be recommended to optimize throughput.

This is a crucial feature for processing printed films or materials with some moisture. It effectively removes volatiles like ink gases and residual moisture from the molten plastic in the extruder. This results in higher-quality, bubble-free pellets without "pinholes."

Garantia & Instalação

- Garantia limitada de 1 ano

Todas as nossas sistemas de reciclagem incluem uma garantia limitada de um ano completa.

- Suporte Técnico e Personalização

We provide full customization, installation guidance, and after-sales support to ensure your line meets your exact needs.

Invista em um Futuro Sustentável

Contact Rumtoo Machinery today to learn more about how our Cutter Compactor Recycling Pelletizing Line can help you transform your plastic waste into valuable resources while contributing to a greener planet.