ターンキーソリューション 完璧なプラスチックフレーク

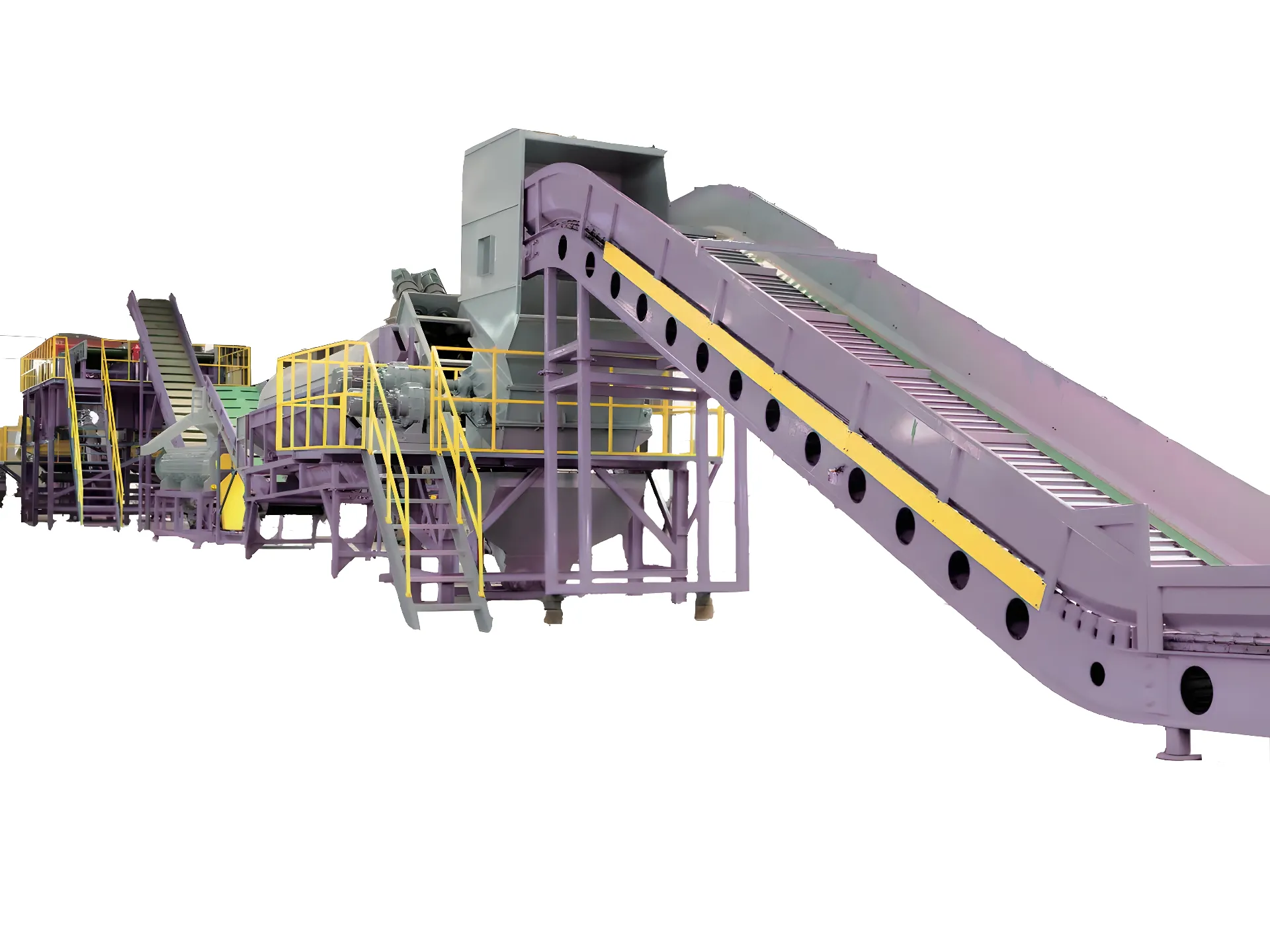

当社は、汚染された使用済みまたは産業廃棄物を、収益性の高い再利用が可能な高純度で高価値のリサイクルフレークに変換する、完全なカスタムメイドのプラスチック洗浄ラインを設計、構築します。

カスタム提案を入手する

高品質リサイクルのパートナー

当社は単に機械を販売するだけではなく、お客様の特定のニーズと長期的な成功のために設計された包括的で信頼性の高いソリューションを提供します。

完全カスタムソリューション

すべてのラインは、入力材料、容量要件、純度目標に合わせて設計されており、最適なパフォーマンスと効率を保証します。

比類のない出力純度

当社の多段階の洗浄、すすぎ、分離プロセスにより、最も頑固な汚染物質も除去され、市場投入可能なフレークが提供されます。

エンドツーエンドのサポート

当社のチームは、初期設計と設置からトレーニングやアフターサービスまで、プロジェクトのライフサイクル全体にわたって専門的なサポートを提供します。

当社のシステムの動作をご覧ください

当社の先進的な PET ボトル洗浄ラインの完全なウォークスルーをご覧ください。原材料からきれいな完成したフレークまでのプロセスが紹介されています。

実績のある4段階洗浄プロセス

各段階は調和して機能するように細心の注意を払って設計されており、材料を段階的に洗浄および精製して、優れた最終製品を生み出します。

サイズダウンと予洗い

梱包された材料やばら積みの材料は、細断または粒状に加工されます。この初期段階では、ばら積みの汚れや細かい粒子を取り除くための乾式前洗浄が行われることがよくあります。

徹底的な洗浄と分離

フレークは高速摩擦洗浄され、浮遊シンクタンクを通過して密度によってプラスチックを分離します (例: PET と PP/PE キャップ)。

温水/冷水すすぎ

オプションの高温洗浄を含む複数のすすぎ段階により、残留接着剤、油、化学汚染物質が除去され、最高の純度が実現します。

乾燥と微粒子除去

遠心脱水機と熱乾燥機により、水分を1%以下にまで低減します。ジグザグ分級機により、残留する埃やラベルを除去します。

標準的なシステム仕様

幅広い標準容量をご用意しており、すべてのシステムは完全にカスタマイズ可能です。以下はPETボトル洗浄ラインの例です。

| パラメータ | 500 kg/hライン | 1000 kg/hライン | 2000 kg/hライン |

|---|---|---|---|

| 適用可能な材料 | PETボトル、HDPE/PPボトル、硬質プラスチック | ||

| 最終製品の水分 | < 1% | ||

| 最終不純物含有量 | 100ppm未満 | ||

| 総設置電力 | 約150kW | 約280kW | 約450kW |

| 水の使用量 | 約5トン/時 | 約8トン/時 | 約12トン/時 |

よくある質問

はい、もちろんです。農業用フィルムや使用済みLDPEフィルムなどの軟質プラスチック向けに、専用の洗浄ラインを設計しています。これらのシステムでは、柔軟な素材向けに最適化された特殊な摩擦洗浄機と脱水プレスを使用しています。

当社のラインは水効率を重視して設計されており、通常、プラスチック1トンあたり1~2トンの淡水を使用します。また、最大80%の処理水をリサイクルできる統合型水処理・循環システムも提供しており、運用コストと環境負荷を大幅に削減します。

設置面積は処理能力と構成部品によって異なります。標準的な1000kg/hのPETボトル洗浄ラインでは、通常約500~600平方メートル(例:長さ60m×幅10m)の面積が必要です。ご提案段階で詳細なレイアウト図をご提供いたします。

高品質のリサイクルプラスチックを生産する準備はできていますか?

今すぐ当社のエンジニアリング チームにご連絡いただければ、無料のコンサルティングと、お客様の正確な仕様に合わせた洗濯物干しラインの詳細な提案をさせていただきます。

無料見積もりをリクエスト