High-Performance Rigid Plastic Shredder: Turn Scrap into Revenue

Engineered for recycling facilities and plastics manufacturers, our shredders effortlessly process tough scrap like ABS, PVC pipes, PC lumps, and purgings, transforming it into valuable, reusable material.

Get a Custom QuoteHow It Works

Achieve efficient shredding in three simple steps.

Step 1: Smart Feeding

Load rigid plastics into the large hopper. The hydraulic ram automatically pushes material toward the rotor for consistent, hands-free processing.

Step 2: Powerful Shredding

The high-torque, low-speed rotor uses powerful shear force to cut through material. It automatically reverses to prevent jams, ensuring continuous operation.

Step 3: Consistent Output

Shredded material passes through an interchangeable screen, producing uniform particles ready for granulation or other downstream processes.

Key Benefits

More than just a machine, it's a partner in boosting your productivity and profit.

High Throughput

An optimized rotor design and powerful drive system maintain stable, high-output performance, even when processing bulky, tough materials.

Built to Last

Features heat-treated, high-strength alloy steel blades for superior wear resistance. The heavy-duty frame ensures long-term reliability in demanding environments.

Intelligent Anti-Jam System

The PLC control system monitors motor load and automatically reverses the rotor to clear potential jams, ensuring continuous, uninterrupted operation.

Turning Challenges into Opportunities

See how our solution solves common industry pain points.

The Problems

- Bulky items and purgings require manual pre-cutting, slowing production.

- Frequent jams and downtime interrupt workflow and reduce efficiency.

- Rapid blade wear leads to frequent replacements and high maintenance costs.

- High levels of dust and noise create a hazardous work environment.

Our Solution

- A wide-mouth hopper and hydraulic ram handle large parts automatically.

- Smart PLC control with auto-reverse function prevents jams for maximum uptime.

- Durable, imported alloy blades extend service life by 2-3x, reducing costs.

- A fully enclosed design minimizes noise and dust, improving workplace safety.

See It In Action

Watch our shredder tackle tough materials with ease.

What Our Clients Say

Hear from clients who have already benefited from our technology.

"This shredder is a game-changer for our ABS purgings! What used to take two workers half a day is now done in under an hour. The output is consistent, which has significantly improved our downstream granulation process."

"We compared several suppliers and chose them for their robust build quality. The machine has been running for nearly two years with almost no issues besides routine blade maintenance. Their after-sales support is also very responsive."

"The safety features and level of automation are impressive. The PLC system makes operation simple and safe. We no longer worry about the risks to our staff when handling large, heavy plastics."

Wide Range of Applications

One machine, versatile enough for numerous rigid plastic recycling scenarios.

Technical Specifications

Find the model that best fits your operational needs.

| Model | Rotor Diameter (mm) | Rotor Knives (pcs) | Stator Knives (pcs) | Max. Capacity (kg/h) | Main Motor Power (kW) | Dimensions (L×W×H, mm) |

|---|---|---|---|---|---|---|

| RTM-2455 | 275 | 24 | 1 | ~400 | 22 | 3250×1500×2350 |

| RTM-3063 | 275 | 30 | 1 | ~500 | 30 | 3250×1750×2350 |

| RTM-3980 | 275 | 39 | 1 | ~700 | 37 | 4150×1900×2450 |

| RTM-48100 | 315 | 48 | 1 | ~900 | 45 | 4700×2550×2650 |

| RTM-57120 | 315 | 57 | 1 | ~1200 | 55 | 5350×2850×2760 |

| RTM-75160 | 350 | 75 | 2 | ~1300 | 75 | 5900×3050×2960 |

Why We're Different

A side-by-side comparison to show why our shredder is the superior choice.

| Feature | Traditional Methods (e.g., Granulators) | Our Rigid Plastic Shredder |

|---|---|---|

| Handling Bulk Material | Poor (Requires pre-cutting, prone to jamming) | Excellent (Hydraulic ram, direct processing) |

| Automation Level | Low (Relies on manual operation) | High (PLC control with auto anti-jam) |

| Operational Stability | Fair (Frequent downtime) | Excellent (Continuous, stable operation) |

| Blade Lifespan | Short (Standard steel, wears quickly) | Long (Imported alloy, 2-3x longer life) |

| Safety | High Risk (More manual intervention) | Very Safe (Enclosed design, smart protection) |

Frequently Asked Questions

Your common questions, answered.

What specific types of rigid plastics can this shredder handle?

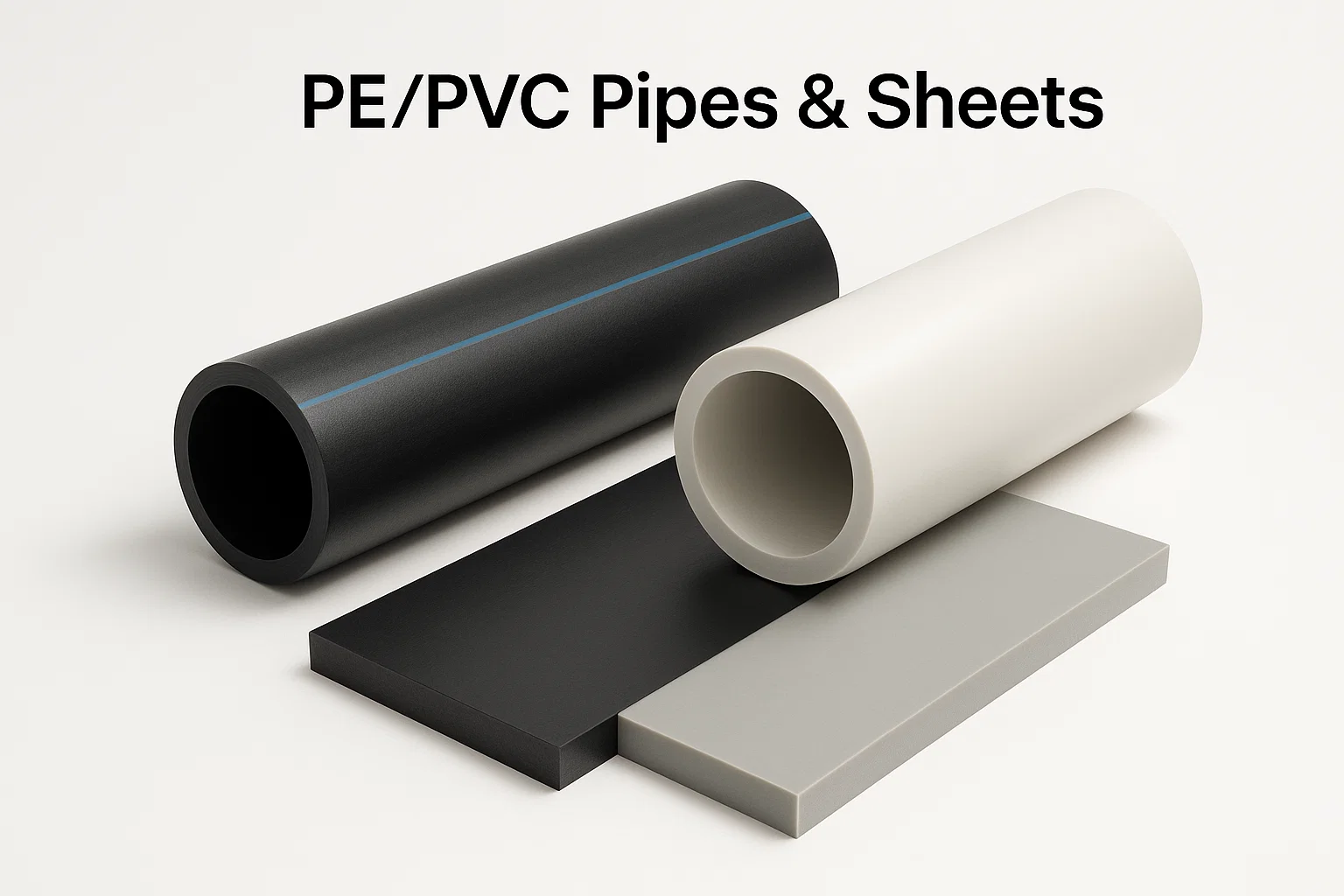

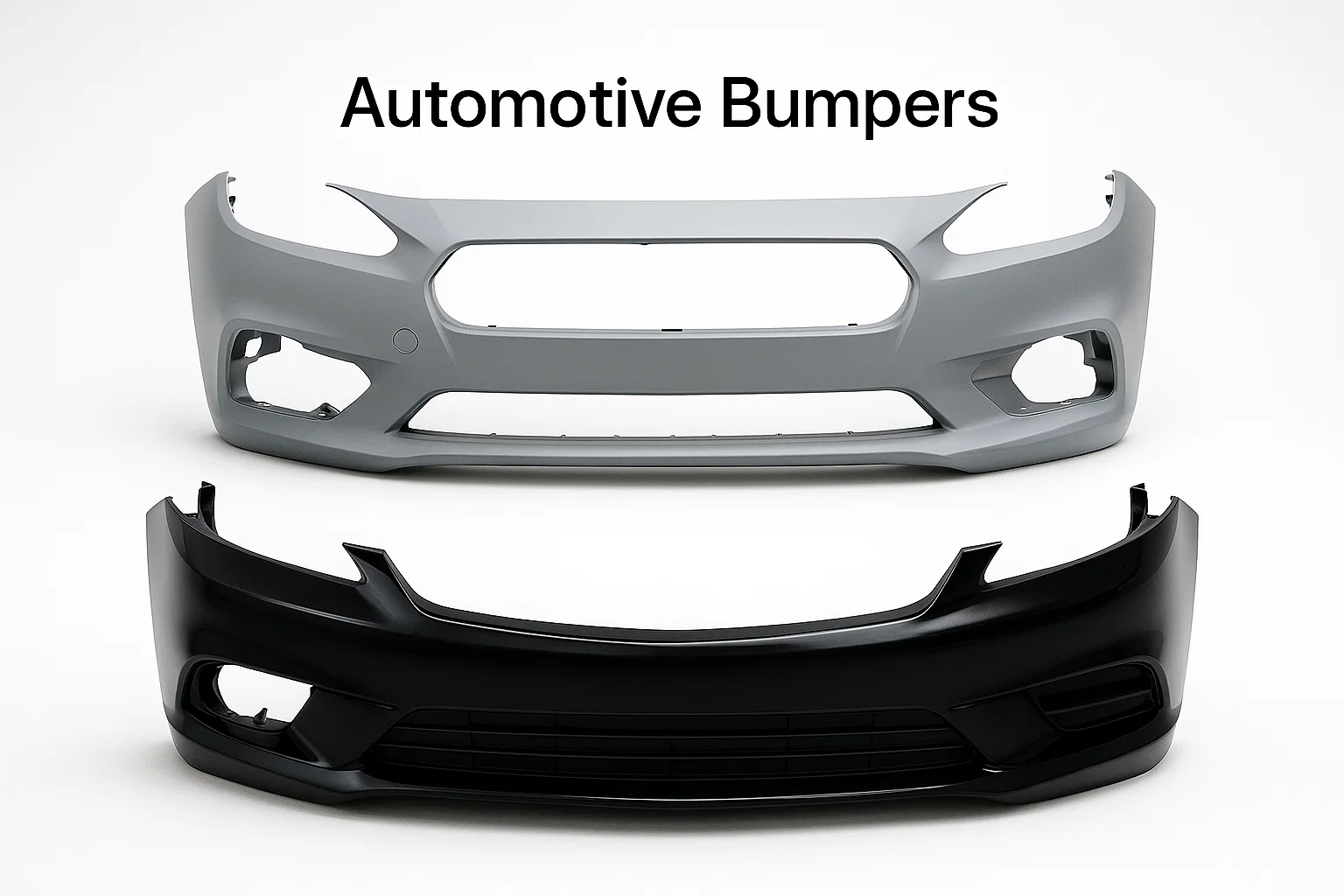

It can process nearly all common rigid plastics, including but not limited to: PVC pipes/sheets, ABS appliance housings, PC sheets, HDPE drums, plastic pallets, automotive bumpers, and various extruder purgings (lumps).

How do I choose the right screen size for my material?

The screen size determines the final particle size. For high-quality granulation, you might choose a smaller hole size (e.g., ø25mm). To maximize throughput, a larger size (e.g., ø50mm) would be better. Our engineers will help you select the optimal screen for your specific application.

Do you provide installation and training?

Yes, we offer comprehensive turnkey services. This includes equipment delivery, on-site installation and commissioning, and professional training for your operators to ensure they can operate and maintain the machine safely and efficiently.

What routine maintenance is required?

Routine tasks include checking blade wear, tensioning belts (if applicable), lubricating bearings, and inspecting the hydraulic system and safety interlocks. We provide a maintenance checklist and recommended intervals with the machine.

What power supply and footprint does it need?

Standard configurations use 380–415V, 50/60Hz, 3‑phase power. Exact footprint depends on the model and optional conveyor/silo, but typical space is 4–6 meters in line length. We can share a layout drawing for your site.

Can you test my material before purchase?

Yes. Send us a small batch (or visit our facility) and we’ll run a trial to validate throughput, particle size, and power consumption, then share a video and test report.

Warranty & Installation

Peace of mind and expert support to get you running fast.

1-Year Limited Warranty

Each of our recycling machines includes a comprehensive one-year limited warranty, giving you peace of mind with your investment.

Expert Installation Support

We provide professional installation services. Our experienced engineers can visit your site to assist with the complete setup and commissioning process.

Ready to Boost Your Recycling Efficiency?

Contact us today. Our technical experts will provide a free material assessment, equipment recommendation, and a detailed quote within 24 hours.