Garis Pemulihan Botol PET Mengubah sampah konsumen setelah penggunaan menjadi sumber daya berharga dalam skala yang belum pernah terjadi sebelumnya. Dengan miliar-miliar botol plastik yang memasuki aliran sampah setiap tahun, teknologi pemrosesan pemulihan yang efisien adalah kunci untuk mengurangi sampah yang dihancurkan, mempertahankan sumber daya, dan membatasi polusi plastik. Garis pemrosesan botol PET yang dirancang dengan benar dapat memproses botol yang digunakan, termasuk kancing dan label, menjadi kotoran yang bersih, dapat digunakan kembali, dengan kepurnaan yang luar biasa, kelembaban yang minim, dan kualitas yang uniform untuk aplikasi berharga tinggi seperti produksi botol baru, serupa tekstil, dan bahan kemasan.

Apakah Anda manajer tempat pemrosesan pemulihan, koordinator keberlanjutan, atau pelopor yang mengeksplorasi usaha-usaha ramah lingkungan, memahami bagaimana garis pemrosesan botol PET beroperasi memungkinkan pengambilan keputusan yang informasi. Panduan ini menguraikan proses kerja, menyorot komponen penting, mengelilingi kapasitas output, dan menyorot manfaat nyata. Mari kita jelajahi bagaimana teknologi ini mengubah sampah menjadi nilai.

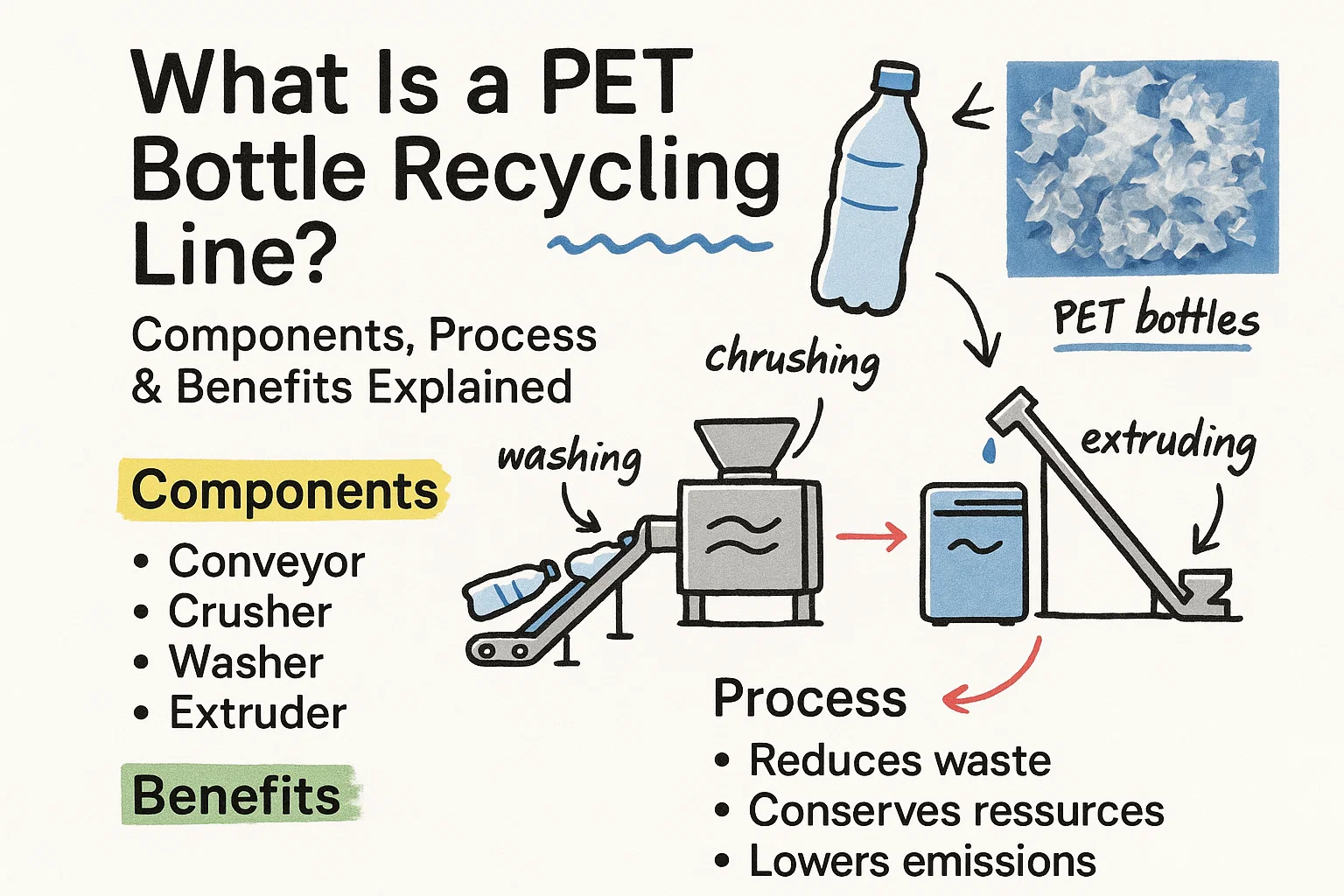

Apa itu garis pemrosesan botol PET dan mengapa hal itu penting?

A Jalur Daur Ulang Botol PET Merupakan sistem pemrosesan yang terpadu dirancang untuk menangani volume tinggi botol PET yang digunakan dari berbagai sumber seperti pengumpulan rumah tangga, tempat penerimaan komersial, atau aliran sampah pemerintah kota. Tidak seperti pengaturan pemilihan dasar, garis ini menangani seluruh siklus hidup botol, dari pemecahan awal hingga produksi kotoran akhir, memastikan pemulihan material maksimal.

Mengapa memperolehnya? Selain memenuhi regulasi lingkungan, garis pemrosesan botol PET yang dirancang dengan baik memberikan nilai penjualan yang nyata:

- Pemulihan Sumber Daya: Memulihkan hingga 95% material PET, mengurangi kebutuhan plastik mentah asli

- Penghematan Biaya: Menurunkan biaya operasional melalui efisiensi otomatis dan pemakaian energi yang rendah

- Keunggulan Pemarketing: Menghasilkan kotoran kelas makanan yang meminta harga tinggi di ekonomi lingkungan

- Dampak lingkungan: Memotong emisi CO2 hingga 70% dibandingkan dengan produksi PET mentah, mendukung tujuannya keberlanjutan global

Pertanyaan yang umum seperti “Bagaimana jalur pemrosesan botol PET dapat meningkatkan keberlanjutan?” atau “Apa keuntungan dari investasi peralatan pemrosesan PET?” mengarahkan operator untuk mengevaluasi sistem ini. Jawabannya terletak dalam proses pemrosesan yang disesuaikan, pengurangan kontaminasi, dan pengembangan output yang menjadikan pemrosesan kembali menjadi layak dan berprofitabilitas.

Minat dalam solusi pemrosesan botol plastik? Selanjutkan membaca untuk melihat bagaimana teknologi ini sesuai dengan operasimu.

Bagaimana Jalur Pemrosesan Botol PET Bekerja? Analisis Langkah demi Langkah

A Jalur Daur Ulang Botol PET beroperasi sebagai sistem yang koordinir yang menghubungkan tahapan yang berurutan untuk mempertahankan dan mempersiapkan PET untuk penggunaan kembali. Dari pemecahan bale botol sampai pengeringan serupa, setiap tahapan membangun di atas tahapan sebelumnya untuk efisiensi end-to-end. Berikut adalah alur yang logis:

1. Pemecahan dan Pemilihan Awal

Bale yang disampingkan datang dan dimasukkan ke mesin pemecahan yang dengan lembut melepaskan botol untuk mencegah kerusakan. Pemilihan awal menghilangkan kontaminan bukan PET seperti kaca atau kertas, mempersiapkan dasar yang bersih untuk pemrosesan.

2. Pemulihan

Botol memasuki unit pemulihan tempat air panas tekanan tinggi menghujani kotoran lepas, residu, dan debu awal. Tahap ini sering menggunakan lingkaran air terkait untuk mencegah gangguan di arah bawah dan meningkatkan kebersihan keseluruhan sambil mengurangi pemakaian air.

3. Pemisahan Label dan Cap

Masing-masing mesin pemutihan label khusus menggunakan jet udara, uap, atau pemutihan mekanik untuk melepaskan adhesif dan label PVC. Cap (biasanya polipropilen) dipisahkan melalui tangki pengapung berdasarkan kepadatan, memungkinkan pemisahan material penuh untuk tingkat kebersihan yang tinggi.

4. Pengurangan Ukuran Melalui Granulasi

Botol-botol utuh bertemu dengan granulator atau pemotong berat untuk memotongnya menjadi serupa jerami sambil memasukkan pemutihan awal. Ini mengurangi volume hingga 80%, membuat pemutihan berikutnya lebih cepat dan efektif.

5. Pembersihan Intensif dengan Geras dan Pembersih Panas

Jerami berputar melalui pemutih geras tinggi kecepatan, tempat putar dan sprays mencuci kotoran keras, minyak, dan glue. Selanjutnya adalah tangki pembersih panas yang diinfuskan dengan soda klorida (natrium hidroksida) dan uap. Kombinasi ini menghilangkan lebih dari 99% kotoran, termasuk protein dan hidrokarbon.

6. Pembersihan dan Deteksi

Detektor metal inline dan pemisah optik memantau logam ferum dan logam non-ferum atau gangguan warna, mengejek sampah dengan presisi. Ini mempertahankan integritas jerami untuk penggunaan akhir yang sensitif.

7. Pengurangan Keringat, Granulasi Kedua, dan Menyaring

Keringat ekstrim diusir melalui pengering sentrifugal, diikuti dengan granulasi kedua untuk konsistensi ukuran. Akhirnya, pengeringan termal mengurangi kelembaban di bawah 0.5%, memberikan jerami kering, siap diwahyung untuk ekstrusi atau dijual.

Pencarian yang berhubungan seperti “langkah-langkah dalam proses pemrosesan botol PET” atau “bagaimana menghilangkan label dari botol PET dengan efisien” menunjukkan kesadaran tentang mekanisme ini. Dengan menanggapinya langsung, fasilitas dapat memecahkan masalah yang umum seperti kualitas piringan yang tidak konsisten atau pemakaian air yang tinggi.

Komponen Utama: Bahan Dasar untuk jalur Pemrosesan Botol PET Anda

Setiap Jalur Daur Ulang Botol PET beroperasi dengan komponen modul yang dirancang untuk keandalan dan skala peningkatan. Daftar ini menyediakan wawasan praktis untuk membantu Anda mengevaluasi pengaturan, termasuk penilaian energi, kebutuhan pemeliharaan, dan mudahnya integrasi:

| Komponen | Fungsi | Tip untuk Penggunaan Optimal |

|---|---|---|

| Mesin Pemecah Bal | Membuka dan menyiapkan bal botol tanpa merusak | Dipasangkan dengan jalur pengangkut untuk aliran yang lancar; efisien menghadapi bal berat 1-5 ton |

| Mesin Pemulihkan Sebelum Pemilihan | Pembersihan panas awal untuk menyebutkan kontaminasi permukaan | Menggunakan deterjen ramah lingkungan untuk mengurangi biaya kimia dengan 20% |

| Mesin Penghapus Label | Menghilangkan atau mencairkan label dengan uap atau penggosokan | Pantau pertumbuhan adhesif; pemugaran ganda piring penggosok memperpanjang umur hingga 50% |

| Detektor Logam | Mengidentifikasi dan mengalirkan keberatan logam setelah penggilingan | Kalibrasi untuk puing kapsul botol; terintegrasi dengan sistem lepas otomatis |

| Granulator/Penghancur | Menggiling botol menjadi serupa daun dengan pembersihan awal internal | Pilih gaya rotor berdasarkan tebal botol; baja yang dikekerasan menawarkan kekuatan |

| Mesin Cuci Gesekan Berkecepatan Tinggi | Membersihkan serupa daun melalui gerakan mekanik dan jet air | Atur kecepatan untuk ukuran serupa; berkurangkan energi dengan pemulihan air cuci |

| Tangki Cuci Panas/Filter Uap | Pembersih dengan solusi alkalis di suhu 80-90°C untuk menghancurkan minyak dan lepas | Pemantauan pH mencegah kelembaban terlalu tinggi, memastikan keutralitas serupa |

| Pengering Sentrifugal | Menghilangkan air ekstraberga melalui putar tinggi | Distribusi frekuensi variabel mengoptimalisir penggunaan energi hingga 15% |

| Pengering Termal | Pengurangan kelembaban akhir di bawah 0.5% untuk stabilitas penyimpanan | Kontrol suhu mencegah kerusakan serupa sementara memastikan penambahan kering yang mendalam |

Elemen-elemen ini, sering kali dapat disesuaikan, memastikan jalur Anda mencapai nilai IV (Viskositas Intrinsik) di atas 0.75, yang penting bagi kelas rPET (PET reciklan) kelas premium. Tertanyakan “Peralatan yang dibutuhkan untuk reciklan PET?” Rangkaian ini mencakup segala tingkatan operasi, dari tingkat awal hingga skala industri.

Kapasitas dan Skalabilitas: Menyesuaikan Output Menurut kebutuhan Anda

Tidak ada operasi pemrosesan sampah yang sama, sehingga kami menawarkan kapasitas yang beragam untuk memenuhi kebutuhan volume anda. Hasil tipikal termasuk: Garis Pemulihan Botol PET : Sesuai untuk pemula atau proyek pilot yang menguji konsep pemrosesan skala kecil

- 500-600 kg/h: Cocok untuk fasilitas menengah yang mengelola pengumpulan regional

- 800-1,000 kg/h: Suited for mid-sized facilities handling regional collections

- 1,000-1,500 kg/h: Menyediakan keseimbangan efisiensi bagi pabrik pengelola sampah kota yang tumbuh

- 1,500-2,000 kg/h: Konfigurasi tinggi permintaan untuk pemroses komersial

- 2,000-2,500 kg/h: Level bisnis untuk operator beroperasi berjumlah besar

- 2,500-3,000 kg/h: Sistem industri yang mengolah aliran sampah kota

Faktor seperti kualitas bahan makan, pasokan energi, dan tingkat otomatisasi mempengaruhi laju ini. Misalnya, pengembangan ke sistem gerak berfrekuensi variabel dapat meningkatkan efisiensi sebesar 15%. Pencarian panjang seperti “Kapasitas jalur pemutih PET untuk 1000 kg per jam” atau “Solusi pengelolaan PET yang dapat diukur untuk bisnis” menunjukkan kebutuhan untuk desain modul yang dapat tumbuh hari ini dan skala besok.

: Memilih jalur pemrosesan botol PET? Manfaat yang nyata dan langkah berikutnya

Berinvestasi di Jalur Daur Ulang Botol PET melampaui peralatan. Ini mempromosikan hari esok yang lebih hijau sambil mempertahankan pertumbuhan keuangan dasar. Fasilitas yang menggunakan sistem ini melaporkan laju pemulihan kotoran yang tinggi 30-50%, masa pengembalian modal yang cepat (sering kali kurang dari 2 tahun), dan komplian dengan standar seperti FDA atau EFSA untuk material berhubungan dengan makanan. Dalam pasar yang diperkirakan mencapai $15 miliar pada 2030, para pengguna awal mendapatkan keunggulan kompetitif.

Memahami seluruh skop proses pengelolaan botol PET membantu Anda membuat keputusan peralatan yang informasi. Dari pengurutan awal hingga produksi kotoran akhir, setiap tahap kontribusi bagi efisiensi sistem keseluruhan dan kualitas output.

Tertarik tentang hal-hal spesifik seperti biaya mesin pengelolaan PET atau tips pemeliharaan untuk jalur pemutih? Para ahli kami menyediakan referensi tentang:

- Perencanaan kapasitas khusus untuk fasilitas Anda

- Peningkatan efisiensi energi untuk mengurangi biaya operasional

- Jadwal pemeliharaan untuk memaksimalkan waktu beroperasi

- Protokol kontrol kualitas untuk produksi kotoran kelas makanan

Siap merubah operasi pengelolaan sampah Anda? Telusuri teknologi terkini kami Sistem Daur Ulang Botol PET dan lihatnya dalam aksi. Di Mesin Rumtoo, kami bekerja sama dengan operator yang berpikir maju seperti Anda untuk mengubah sampah PET menjadi kesuksesan berkelanjutan. Hubungi kami sekarang untuk mendiskusikan solusi khusus, menjadwalkan demo, atau aransemen kunjungan tempat. Bersama-sama, kita membangun masa depan yang berkelanjutan.