Mesin Penghancur Plastik Otomatis untuk Produksi Bubuk Halus

Disc-type grinding system for converting plastic granules into controlled powder for recycling and compounding. Typical product size range is 20 to 100 mesh, depending on disc configuration and operating gap. Recommended feed is clean granules, with a maximum size of 14 mm.

Dapatkan Keterangan Kustom

Feed and Discharge System

Metered infeed and stable discharge are primary drivers of output consistency. Typical layouts include vibratory dosing, guided chamber flow, and pneumatic transfer to separation and collection.

Mekanisme Pemberian Makanan yang Efisien

Material yang ditujukan untuk penghancuran dimasukkan dengan lancar ke dalam cakram penghancur yang berputar tetap dan berkecepatan tinggi melalui pengumpan bergetar yang dikontrol secara presisi, guna memastikan aliran material yang konsisten.

Gaya Sentrifugal Dinamis

Cakram bagian dalam yang terintegrasi memanfaatkan gaya sentrifugal untuk memandu material secara ahli melalui cakram penghancur, mendorongnya ke ruang eksternal untuk pembuangan yang efisien.

Pengangkutan Material Terpadu

Bahan yang dihaluskan selanjutnya dibantu oleh sistem pengangkutan hilir, yang menjamin operasi lancar dan mencegah penyumbatan.

Grinding Workflow

Process sequence from granule feed through disc milling to powder collection. Stable operating conditions are set by disc gap, disc tooth geometry, and temperature management.

Pemberian Bahan

Plastik granular (maks. 14 mm) dimasukkan ke dalam alat penghancur melalui pengumpan bergetar.

Penghancuran Kecepatan Tinggi

Cakram berputar berkecepatan tinggi menggiling bahan menjadi bubuk halus.

Pelepasan Sentrifugal

Gaya sentrifugal mendorong bubuk ke ruang eksternal untuk dikumpulkan.

Sistem Penyampaian

Sistem pengangkutan hilir mengangkut bubuk akhir, mencegah penyumbatan.

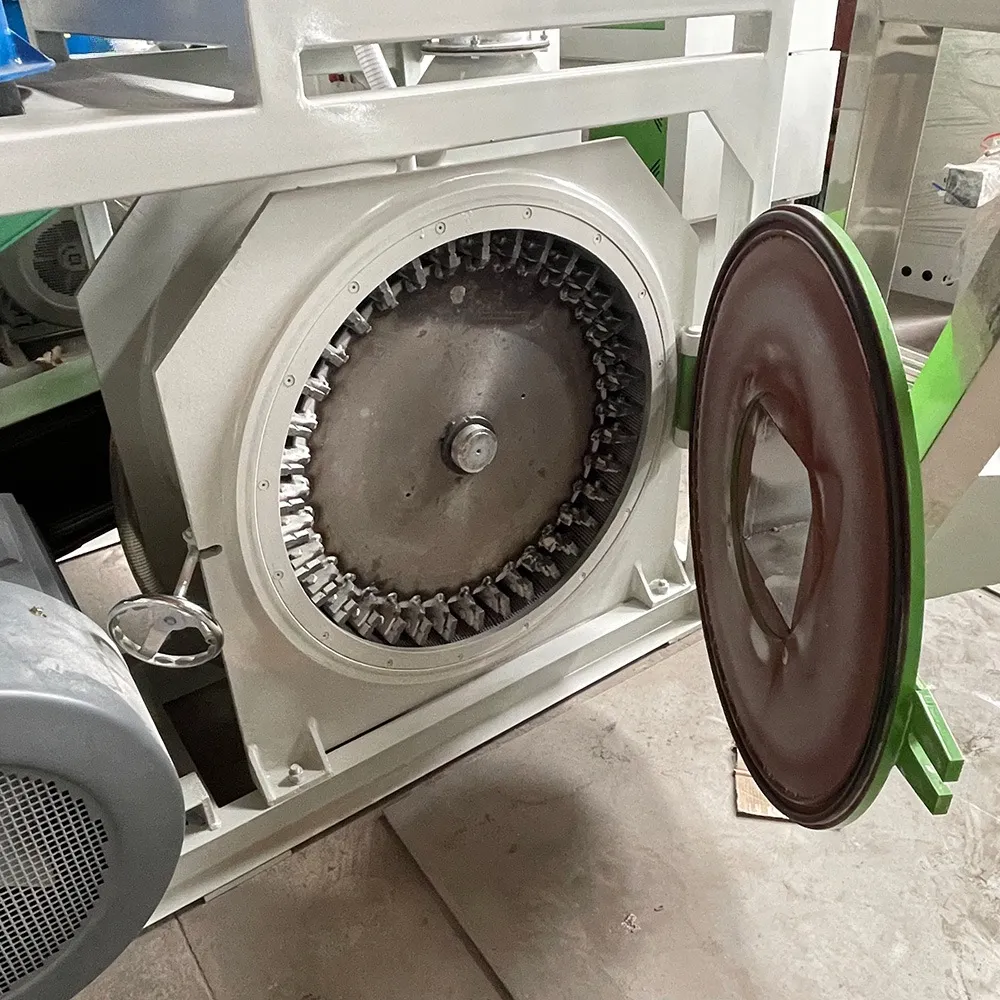

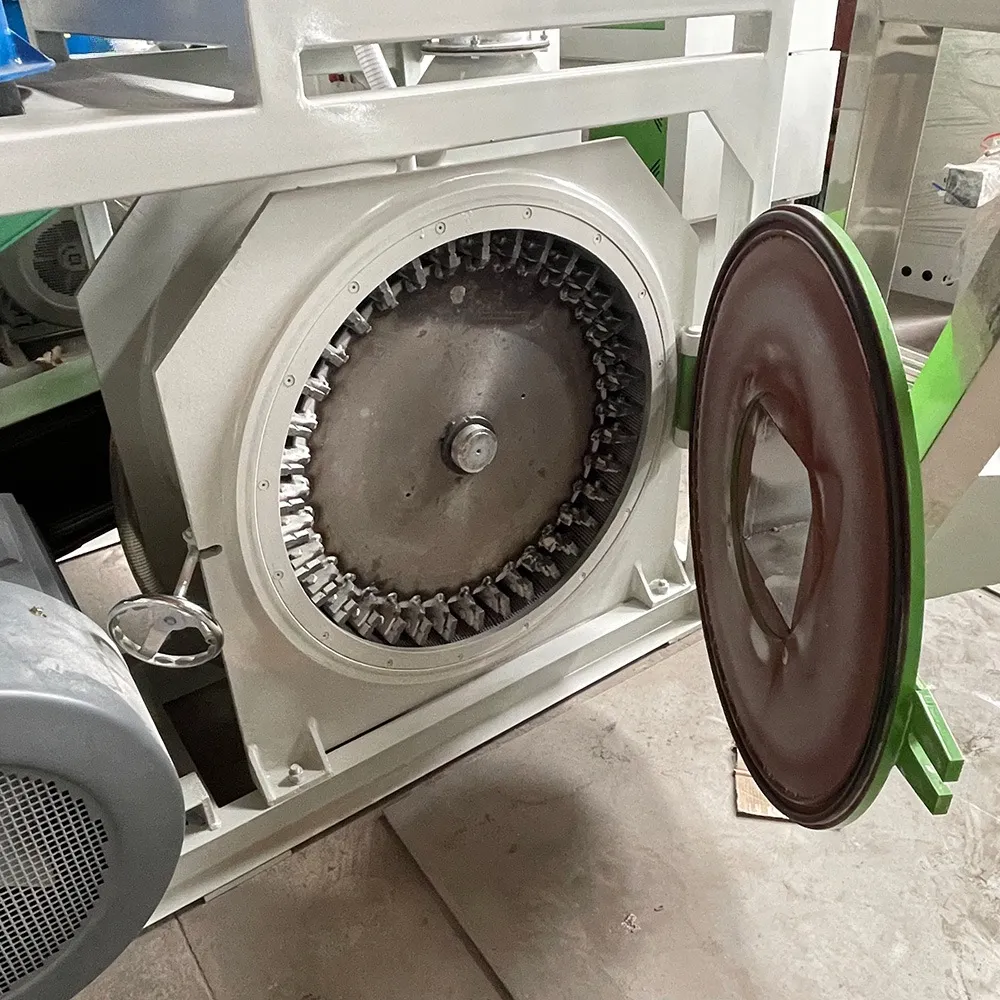

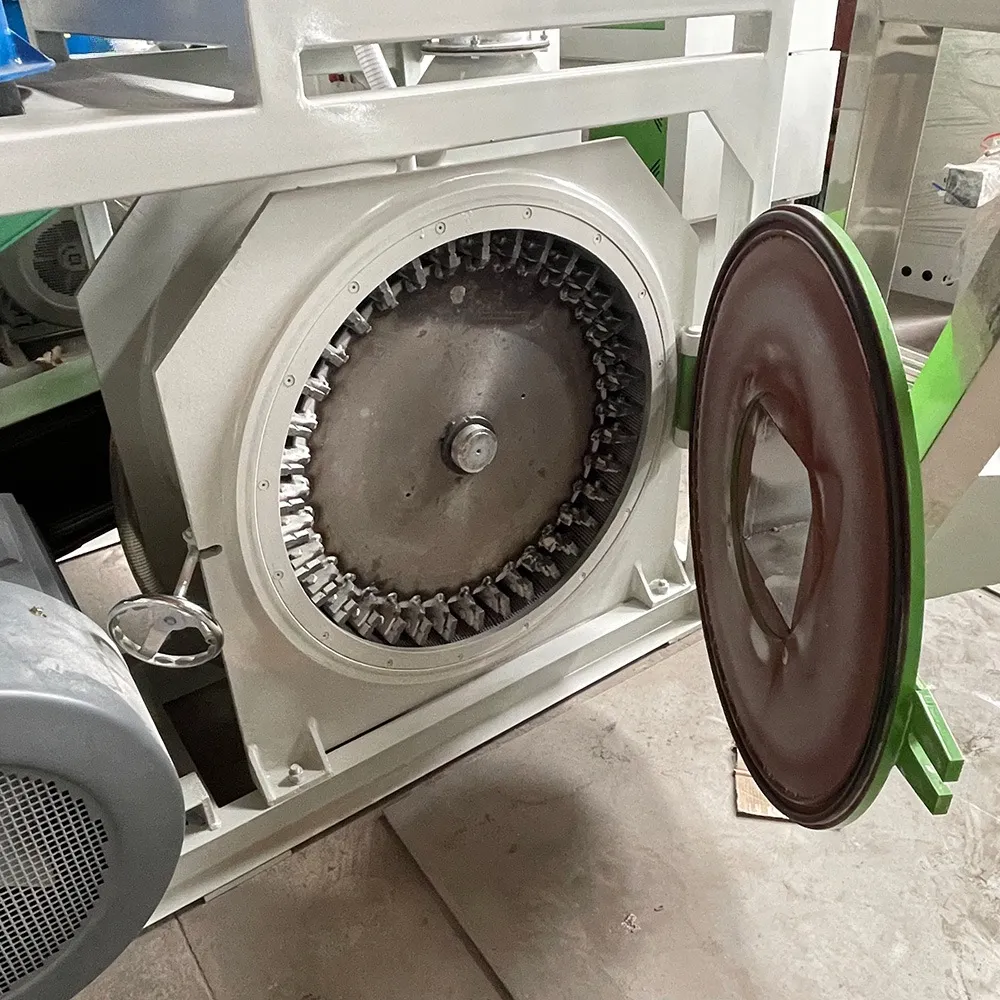

Equipment Photos

Reference images for layout planning, access clearances, and component identification.

Spesifikasi Model

Compare model sizing, installed motor power, and rated capacity ranges for preliminary selection.

| Model | Daya (Pengumpan Getar) | Diameter Putar (Motor Utama) | Kekuatan Kipas | Jumlah Bilah | Diameter Layar Getaran | Kapasitas Produksi (kg/jam) | Berat Peralatan (KG) |

|---|---|---|---|---|---|---|---|

| TM-500 | 2,2 kW | 500 mm2 | 4KW | 12+24 | 800mm | 150-200 | 1500 |

| TM-600 | 4KW | 600mm | 5,5 KW | 13+26 | 1000mm | 200-450 | 2000 |

| TM-800 | 4KW | 800mm | 11KW | 15+32 | 1200mm | 500-800 | 2800 |

System Configuration

A fine grinding installation is typically delivered as a system. Define upstream feed preparation, separation and collection, and optional size classification to match your target mesh and throughput.

| Module | Fungsi | When Needed | Notes / Interfaces |

|---|---|---|---|

| Granule dosing (vibratory feeder) | Stable mass flow into the mill | Recommended for consistent output | Match feed rate to disc loading and target mesh |

| Metal separation (magnet) | Protects discs and chamber | Recommended when feed contamination risk exists | Install before dosing for best protection |

| Air conveying line | Powder transport and heat removal | Typical for powder transfer to separation | Airflow is tied to fan power and duct routing |

| Cyclone dust separator | Primary powder separation | Available for dust removal and product collection | Typically paired with final filtration for fines capture |

| Dust collector (bag filter) | Final fines capture | Typically required for clean discharge | Confirm site dust handling and disposal method |

| Water cooling (optional) | Removes process heat from the grinding zone | When heat-sensitive resins or fine mesh targets increase temperature | Confirm water supply or closed-loop cooling, and connection requirements on quotation |

| Screening / classification (optional) | Narrower size distribution | When tight oversize control is required | Can be paired with return loop for oversize recycle |

| Oversize return loop (optional) | Reprocesses oversize fraction | When classification is installed | Improves yield at tighter mesh targets |

| Sound enclosure (optional) | Noise reduction | When installed near operators | Confirm access panels for maintenance |

Throughput Performance

Throughput depends on model size, disc configuration, target mesh, and polymer behavior under shear. Use the specification table for shortlisting, then confirm capacity against your resin, feed temperature, and required powder fineness.

Efisiensi Output Tinggi

Continuous-duty design supports steady production when feed rate, disc gap, and airflow are matched.

Material-Dependent Capacity

Hardness, brittleness, and impact behavior affect disc loading and the achievable kg/h at a given mesh.

Mesh Target Tradeoff

Finer powder targets generally reduce throughput and increase heat generation. Define acceptable size distribution before final sizing.

Thermal Management

Disc milling generates heat that can affect resin properties and powder flowability. Temperature control and internal cooling help stabilize the grinding zone and reduce thermal spikes during continuous operation.

Kontrol Suhu Otomatis

Stabilizes the grinding zone temperature to support repeatable operation across different resin batches.

Optional Water Cooling

Water cooling can be configured to remove process heat, reduce melt risk, and maintain stable powder discharge.

Process Stability

Stable temperature supports consistent gap setting behavior and helps reduce variability in size distribution.

Maintenance and Wear Parts

Uptime is driven by disc wear, access for adjustment, and cleaning time between resin changes. Evaluate wear-part intervals and service procedure against abrasiveness, contamination risk, and shift schedule.

Disc Wear Life

Disc design targets long service intervals to reduce resharpening frequency and planned downtime.

Adjustment and Replacement

Disc gap adjustment and disc replacement are designed to be performed quickly to restore output consistency.

Cleaning Access

Access design affects changeover time when switching polymers, colors, or additive packages.

Operating Cost Drivers

Cost per kilogram is driven by energy input, wear parts, and operator time. Confirm utilities, consumables, and maintenance intervals during quotation to estimate unit economics for your mesh target.

Energy per Kilogram

kWh/kg varies with resin type, fineness target, and airflow settings. Finer mesh targets typically increase energy input.

Wear Parts

Disc service interval and resharpening/replacement plan are primary consumable drivers for long-run operations.

Labor and Changeover

Feeding, monitoring, and cleaning time affect labor cost. Faster access can reduce changeover losses between runs.

System Comparison

Side-by-side view of output consistency, maintenance burden, and control approach for equipment evaluation.

| Fitur | Conventional Systems | Temperature-Controlled Disc Mill |

|---|---|---|

| Kualitas Keluaran | Tidak konsisten, berdebu tinggi | Serbuk halus dan seragam |

| Biaya Operasional | Tinggi (energi, suku cadang, tenaga kerja) | Rendah (hemat energi, tahan lama) |

| Pemeliharaan | Sering, kompleks | Akses minimal dan mudah |

| Kontrol | Manual, tidak tepat | Kontrol suhu otomatis |

Polymer Compatibility

Input resin brittleness, hardness, and impact behavior affect achievable mesh and stable disc loading. Confirm resin type and feed condition before final model selection.

Suitable Resin Types

Medium-hard, brittle, or high-impact resins including PE, PVC, and PC granules.

Feed Form and Size

Granular feed is recommended. Maximum feed size is 14 mm for stable metering and disc loading.

Particle Size Control

Final size distribution is determined by disc tooth geometry, operating gap, and material response to shear. Define target mesh and allowable oversize when specifying the system.

Typical Size Range

20 to 100 mesh, depending on disc configuration and operating settings.

Optional Screening

Screening can be integrated when tighter control of oversize or a narrower cut is required.

Warranty and Service Terms

Warranty scope, exclusions, and service response are defined in the quotation and sales contract. Align coverage expectations with operating hours and maintenance plan.

Standard Warranty

Standard warranty term is 12 months.

Technical Support

Lifetime technical support is offered. On-site support and extended coverage depend on the selected service package.

Installation and Utilities

Define site utilities and layout constraints early to avoid capacity losses from poor duct routing, insufficient cooling, or restricted service access. Final requirements are confirmed on quotation.

| Requirement | What to Provide | Mengapa Itu Penting | Practical Notes |

|---|---|---|---|

| Electrical power | Stable supply for mill, feeder, and fan motors | Sets achievable airflow and throughput stability | Confirm voltage/frequency and total installed power from selected model |

| Water cooling (optional) | Water supply or closed-loop cooling circuit | Controls process heat and supports stable powder production | Confirm connection size, flow, and temperature limits during sizing |

| Ducting and dust handling | Routing for conveying air, separation, and collection | Affects pressure loss, separation efficiency, and housekeeping | Minimize sharp bends and long runs to reduce pressure drop |

| Floor space and access | Service clearance around the mill and collection | Determines maintenance time and safe handling of wear parts | Plan access for disc adjustment, cleaning, and filter maintenance |

| Feed preparation | Clean, consistent granules within size limits | Reduces wear and improves powder consistency | Consider screening and metal separation upstream when needed |

Quote Request

Share resin type, target mesh, required capacity, and available utilities to confirm configuration and quotation.

Kami menghormati privasi Anda. Informasi Anda hanya akan digunakan untuk mendiskusikan proyek Anda.