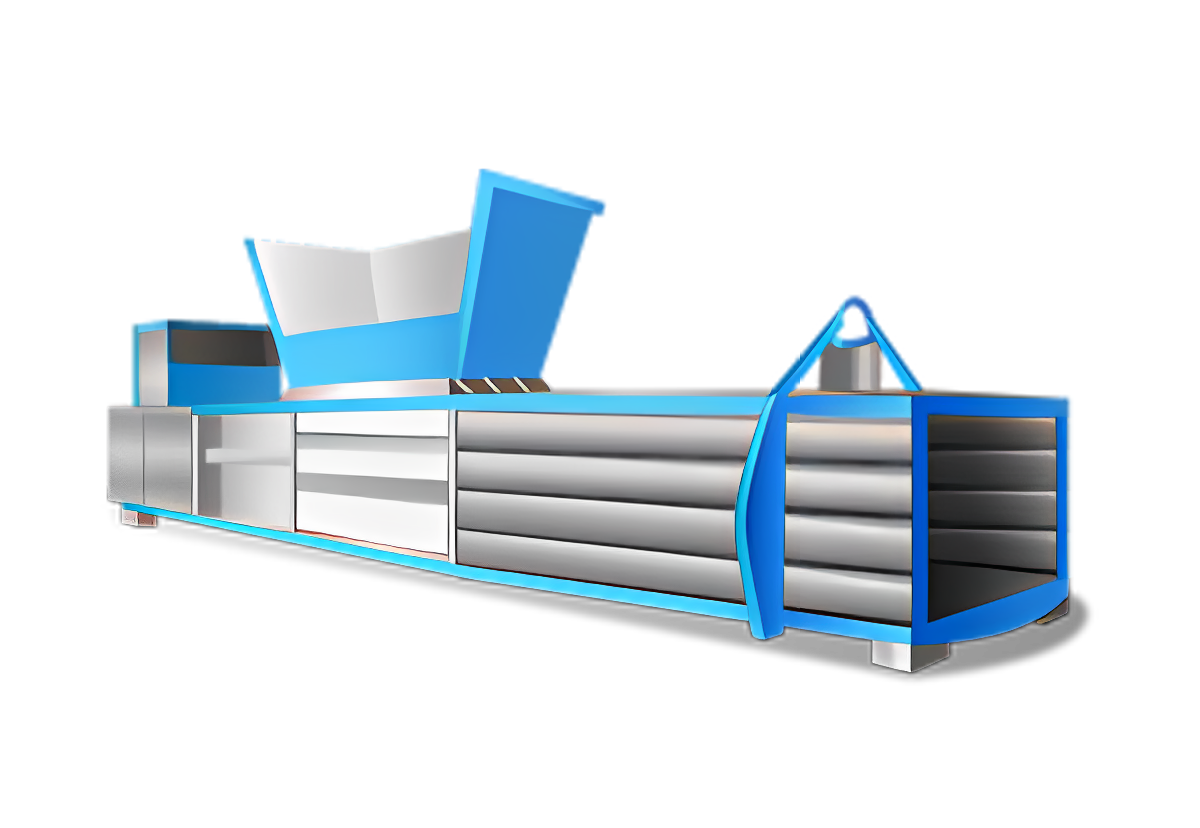

Mesin Baler Industri untuk Mengurangi Biaya Logistik

Kompres film plastik, botol PET, kardus, dan serat menjadi balok padat yang siap diangkut. Pilih konfigurasi vertikal, horizontal, semi-otomatis, atau otomatis sepenuhnya—disesuaikan dengan material dan kapasitas produksi Anda.

Dirancang untuk Pengemasan Bal yang Andal dan Berkepadatan Tinggi

-

Daya Pemadatan Tinggi, Hasil Stabil

Desain hidraulik yang dioptimalkan, struktur rangka yang kokoh, dan pemandu ram yang akurat untuk kepadatan bal yang konsisten—ideal untuk penyimpanan dan pengangkutan.

-

Dikonfigurasi sesuai dengan Material & Alur Kerja Anda

Pilih ukuran ruang, metode pengikatan, jenis pemberian pakan (manual, corong, konveyor), dan tingkat otomatisasi yang sesuai dengan lini produksi dan volume harian Anda.

-

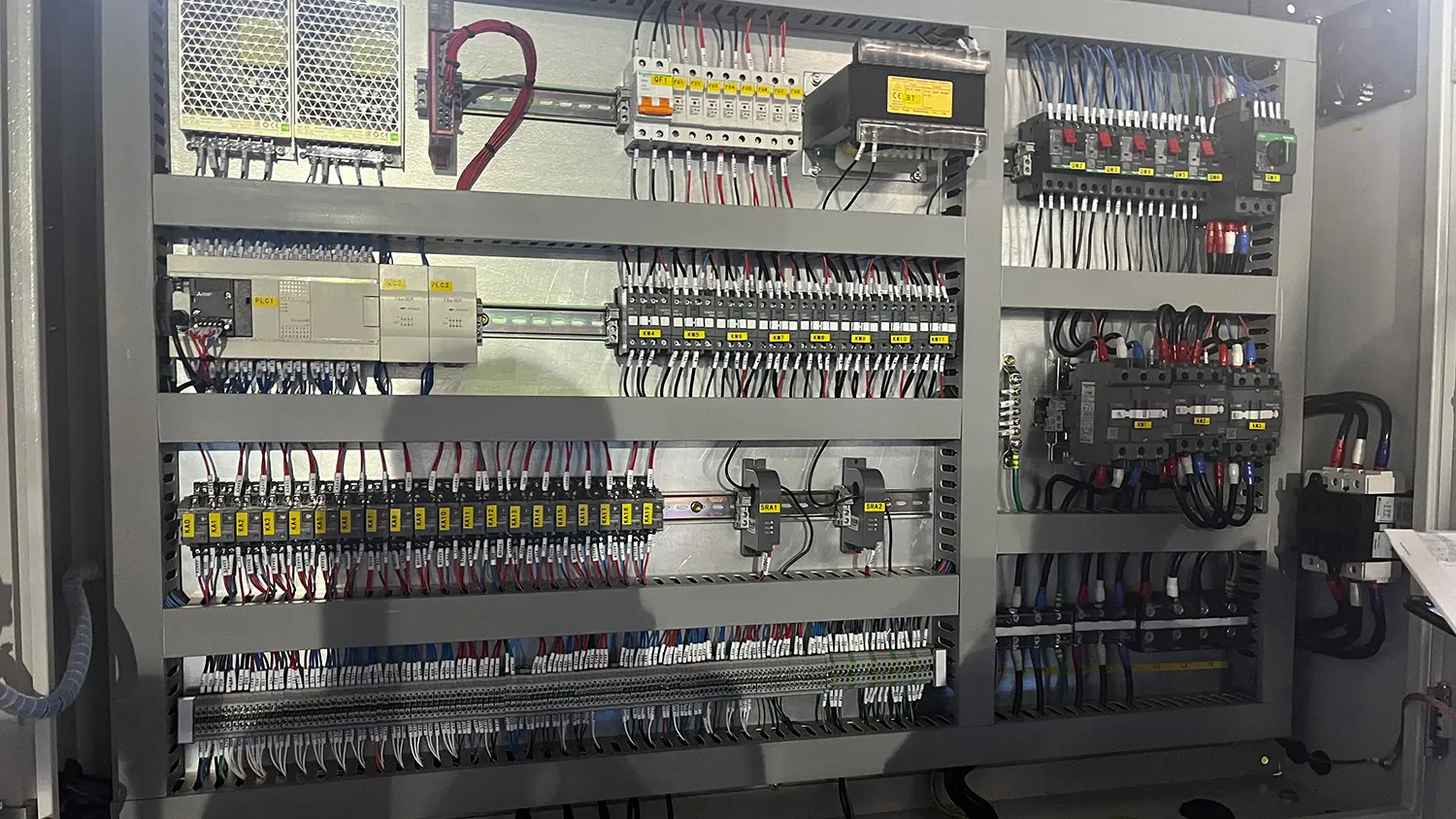

Dukungan Teknik dari Penawaran Harga hingga Pemasangan

Kami membantu Anda menentukan target pengemasan jerami, tata letak, utilitas, keselamatan, dan integrasi—serta dukungan jarak jauh dan di lokasi untuk kelancaran peningkatan produksi.

Saksikan Mesin Pengepak Bal Beraksi

Saksikan demonstrasi pengemasan jerami horizontal—pemuatan, pemadatan, pengikatan, dan pengeluaran jerami dengan cepat.

Dirancang untuk Kelancaran Produksi, Keamanan, dan Biaya Operasional Rendah

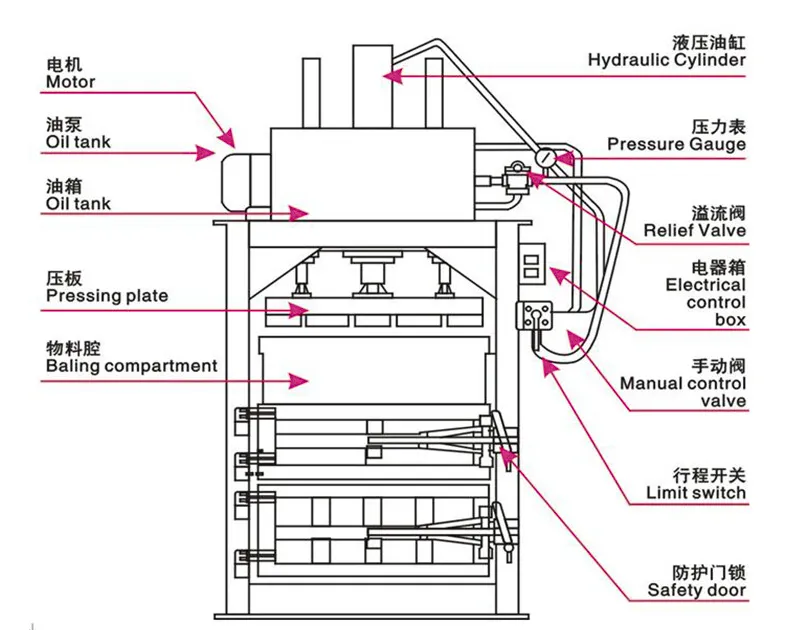

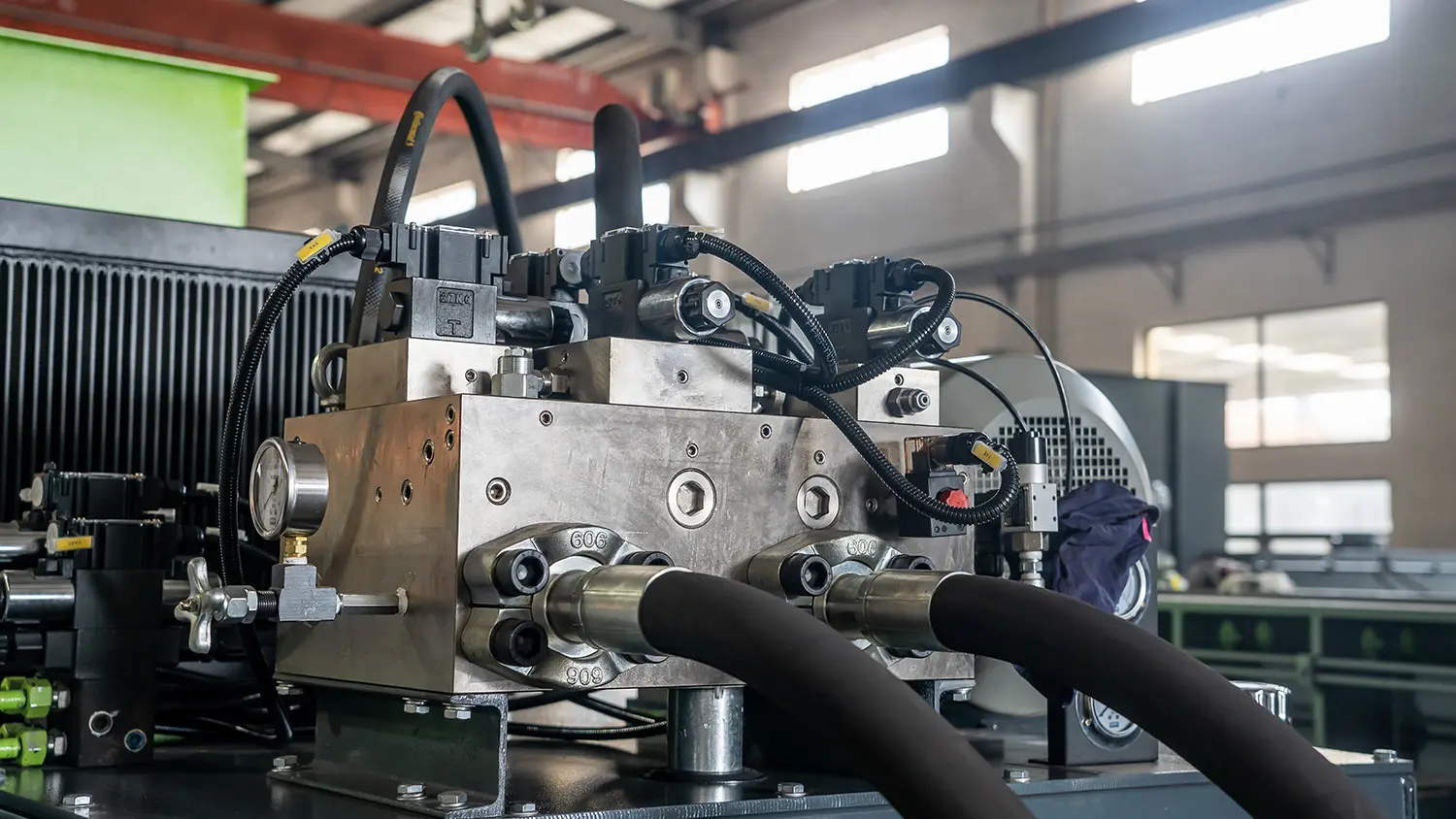

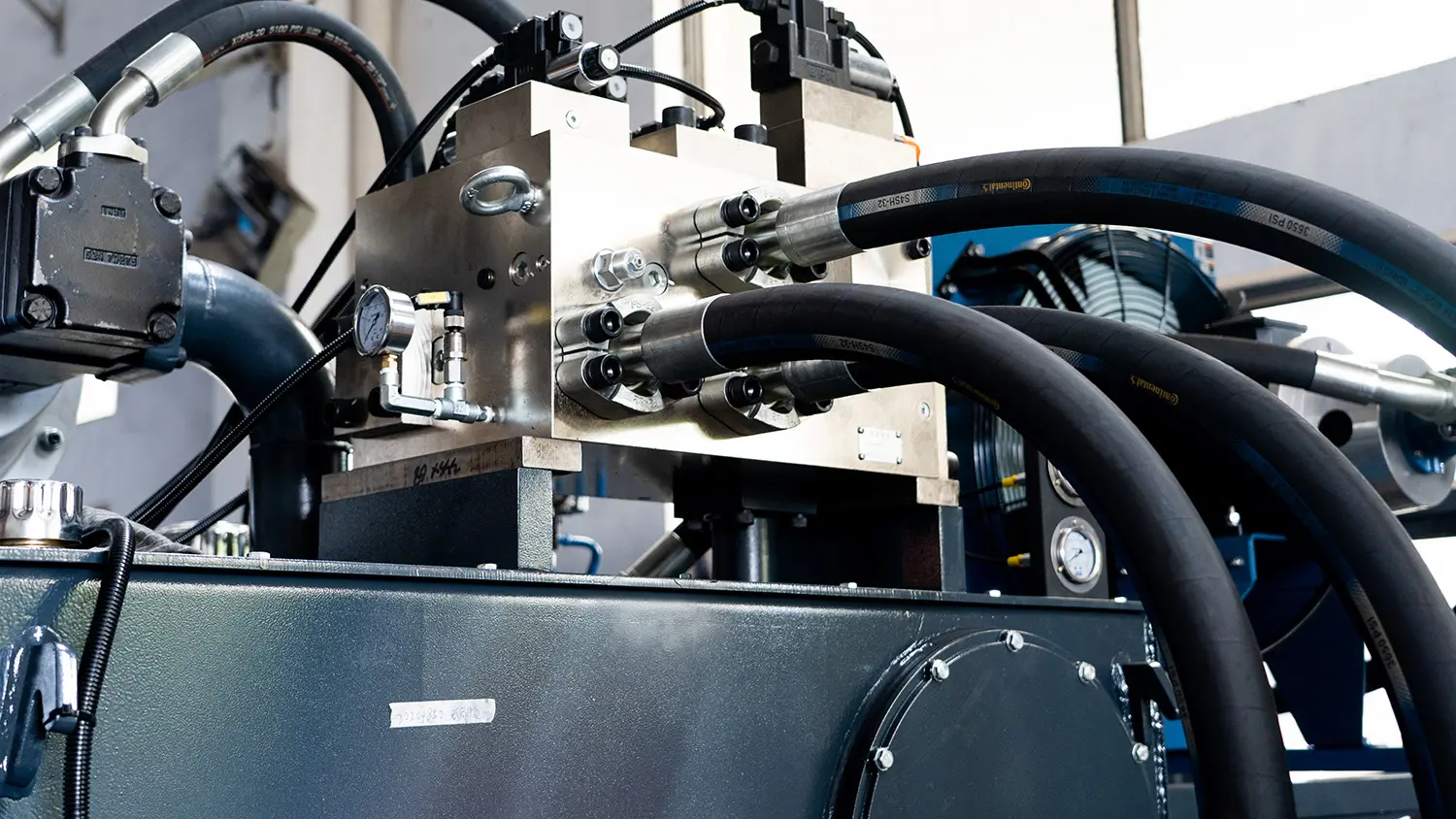

- Sistem Hidrolik Tugas Berat:

Katup berkualitas tinggi, kontrol tekanan yang stabil, dan silinder yang kokoh untuk pengoperasian terus menerus.

- Kunci Pengaman:

Pengunci pintu/gerbang, tombol berhenti darurat, dan bagian bergerak yang terlindungi membantu melindungi operator dan peralatan.

- Kemampuan Multi-Material:

Dari botol dan plastik kaku hingga film, OCC, dan serat tekstil—pilih ruang dan metode pengikatan yang tepat.

- Pengeluaran Bale Cepat:

Mekanisme pengeluaran material yang efisien mengurangi waktu siklus dan menjaga lini produksi tetap berjalan.

- Pengoperasian Hemat Energi:

Unit catu daya yang efisien dan siklus pemadatan yang dioptimalkan mengurangi konsumsi kWh per bal.

- Integrasi Saluran Mudah:

Bekerja dengan konveyor, mesin pelubang, mesin penghancur, dan sistem pemasukan jalur pencucian untuk daur ulang dari ujung ke ujung.

Mesin Pengepres Vertikal vs. Horizontal

Gunakan perbandingan singkat ini untuk memilih jenis mesin pengepak yang tepat sesuai dengan kebutuhan Anda, kapasitas produksi, dan otomatisasi.

Mesin Pengepak Vertikal

Desain ringkas dan hemat biaya untuk pengemasan bal dalam volume rendah hingga menengah di gudang, toko ritel, dan lokasi daur ulang yang lebih kecil.

- Terbaik untuk: ruang sempit, pemberian makan terputus-putus, pemuatan manual/bantuan.

- Bahan: Kardus/OCC, plastik lunak, kemasan ringan, tekstil/serat.

- Mengapa memilih: Pengoperasian sederhana, biaya modal lebih rendah, pemasangan mudah.

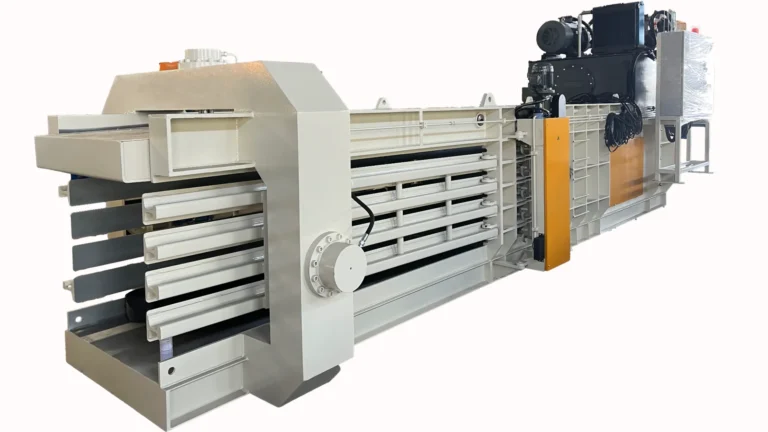

Mesin Pengepak Bal Horizontal

Dirancang untuk throughput yang lebih tinggi dan integrasi jalur kontinu—ideal untuk operasi pengumpanan konveyor dan kontrol kepadatan bal yang stabil.

- Terbaik untuk: Lokasi dengan volume menengah hingga tinggi, pemberian pakan berkelanjutan, otomatisasi.

- Bahan: Botol PET, film, kertas/karton, bahan daur ulang campuran.

- Mengapa memilih: Hasil produksi lebih tinggi, ukuran bal yang konsisten, integrasi hulu yang lebih mudah.

Aplikasi Umum

Pilih jenis dan konfigurasi mesin pengepak berdasarkan kepadatan curah, kadar air, tingkat kontaminasi, dan berat bal yang dibutuhkan.

- Botol PET & Kantong Serpihan

Kompres botol dan kemasan ringan menjadi balok-balok seragam untuk transportasi yang ekonomis.

- Film & Tenun PP/PE

Tangani film tebal dan rafia dengan struktur anti-pantulan dan pilihan pengikatan yang stabil.

- Limbah OCC & Kertas

Menghasilkan bal yang rapi, mudah ditumpuk, dan memenuhi persyaratan pabrik pengolahan selanjutnya.

- Tekstil & Serat

Mesin pengepres vertikal memadatkan serat, kain non-anyaman, dan sisa potongan untuk penyimpanan dan pengiriman.

Model Baler

Telusuri berdasarkan tingkat otomatisasi dan material target. Setiap model dapat dikonfigurasi untuk ukuran ruang, metode pengikatan, dan jenis pemasukan.

Mesin Pengepak Bal Horizontal Semi-Otomatis Premium

Dirancang untuk menghasilkan bal yang konsisten dan pengoperasian yang mudah—ideal untuk film, botol, OCC, dan kemasan campuran pada kapasitas produksi menengah.

Baca Lebih Banyak →

Mesin Pengepres Otomatis Sepenuhnya 100 Ton

Pengepresan otomatis berdaya tinggi untuk material yang sulit dan target kepadatan yang lebih tinggi—dirancang untuk integrasi lini produksi berkelanjutan.

Baca Lebih Banyak →

Mesin Pengepres Kertas dan Plastik Bekas Otomatis

Mesin pengepres otomatis serbaguna untuk aliran campuran—desain ruang seimbang untuk kertas, karton, dan plastik dengan pengikatan yang stabil.

Baca Lebih Banyak →

Mesin Baler Botol PET

Dioptimalkan untuk material ringan dan elastis—menghasilkan bal PET yang rapi dan siap diangkut dengan siklus kompresi yang andal.

Baca Lebih Banyak →

Mesin Baling Kertas Limbah

Dirancang untuk limbah OCC dan kertas dengan penataan bal yang kuat—ideal untuk pabrik, MRF, dan operasi daur ulang kertas.

Baca Lebih Banyak →

Mesin Baling Manual

Pengepakan sederhana dan hemat biaya untuk lokasi kecil—paling cocok untuk kemasan kertas dan plastik dengan volume rendah hingga sedang.

Baca Lebih Banyak →

Baler Hidraulik Sepenuhnya Otomatis Horisontal

Pengemasan bal kontinu dengan throughput tinggi dan sistem hidrolik yang andal—ideal untuk jalur konveyor dan kontrol kepadatan bal yang konsisten.

Baca Lebih Banyak →

Mesin Pengepres Daur Ulang Kertas & Karton

Dirancang khusus untuk aliran karton dan kertas—pembentukan dan pengikatan bal yang stabil untuk kebutuhan daur ulang kertas selanjutnya.

Baca Lebih Banyak →

Mesin Pengepres Botol & Kaleng PET

Dirancang untuk daur ulang wadah minuman—mampu menangani botol dan kaleng dengan pemadatan yang konsisten untuk menghasilkan balok padat yang dapat ditumpuk.

Baca Lebih Banyak →Contoh Spesifikasi Teknis

Berikut adalah beberapa contoh yang dapat dipilih. Kami dapat menyesuaikan tekanan, ukuran ruang, metode pengikatan, dan otomatisasi.

| Model | RTM300WB7070 | RTM400WB7280 | RTM400WS7280 | RTM1000WS110125 |

|---|---|---|---|---|

| Kekuatan Pers | 30 ton | 40 ton | 40 ton | 100 ton |

| Motor Utama | 11 kW | 11 kW | 11 kW | 55kW |

| Mengikat Kawat | 3 baris | 4 baris | 4 baris | 5 baris |

| Bukaan Masukan (P × L) | 700 × 690 mm | 1000 × 700 mm | 1000 × 690 mm | 2080 × 1076 mm |

| Ukuran Bal (P × L × T) | 900 × 700 × 700 mm | 1000 × 720 × 800 mm | Panjang × 720 × 800 mm | Panjang × 1100 × 1250 mm |

| Kepadatan Bale (OCC) | 400–500 kg/m³ | 400–500 kg/m³ | 350–450 kg/m³ | 400–500 kg/m³ |

| Hasil produksi | 0,5–1 t/jam | 0,5–1 t/jam | 0,5–1 t/jam | 5–8 t/jam |

| Berat Mesin | 4 ton | 4 ton | 5 ton | 16,5 ton |

Garansi & Instalasi

Kami mendukung proyek Anda bahkan setelah pengiriman—memastikan pengoperasian yang aman, kualitas bal yang stabil, dan waktu operasional yang dapat diprediksi.

-

Garansi Suku Cadang 12 Bulan

Semua komponen dilindungi dari cacat material dan pengerjaan dalam penggunaan normal.

-

Pengoperasian dan Pelatihan

Dukungan di lokasi atau jarak jauh untuk instalasi, uji coba, pemeriksaan keselamatan, dan pelatihan operator.

-

Dukungan Teknis Seumur Hidup

Layanan diagnostik dan dukungan suku cadang untuk menjaga agar mesin pengepak jerami Anda tetap beroperasi secara efisien dalam jangka panjang.

Pertanyaan yang Sering Diajukan

Mesin pengepres vertikal ideal untuk area yang lebih kecil dan volume produksi rendah hingga menengah. Mesin pengepres horizontal paling cocok untuk kapasitas produksi yang lebih tinggi, jalur produksi yang menggunakan konveyor, dan hasil pengepresan yang konsisten dengan penanganan manual yang lebih sedikit.

Bahan-bahan umum meliputi botol PET, film PP/PE, tas anyaman, OCC/karton, kertas, serat tekstil, dan kemasan ringan campuran—tergantung pada ukuran ruang dan metode pemberian makan.

Kami mulai dari persyaratan pembeli hilir dan logistik Anda (pemuatan kontainer, batasan forklift). Kemudian kami mencocokkan gaya tekan, dimensi ruang, dan garis pengikat untuk mencapai kepadatan yang stabil.

Ya. Kami dapat mendesain konveyor pemasukan, corong, perforator, dan interlock listrik sehingga mesin pengepres bekerja dengan lancar bersama jalur daur ulang Anda yang sudah ada.

Jenis material dan densitas curah, kadar air, gaya tekan, ukuran ruang, dan pengaturan siklus. Kami menyesuaikan parameter hidrolik dan kontrol untuk menstabilkan densitas dan mengurangi efek pegas balik.

Waktu tunggu bervariasi tergantung konfigurasi dan volume pesanan. Model standar biasanya membutuhkan waktu 4–6 minggu; penambahan komponen dan otomatisasi khusus dapat menambah waktu. Hubungi kami untuk jadwal yang tepat.

Siap untuk menstandarkan bal jerami Anda dan memangkas biaya transportasi?

Kirimkan jenis material Anda, kapasitas produksi per jam, dan ukuran bal yang ditargetkan—teknisi kami akan merekomendasikan konfigurasi mesin pengepak bal terbaik.

Dapatkan Penawaran Anda