Soft Plastic Recycling Lines: Sustainable LDPE/PP Film Solutions

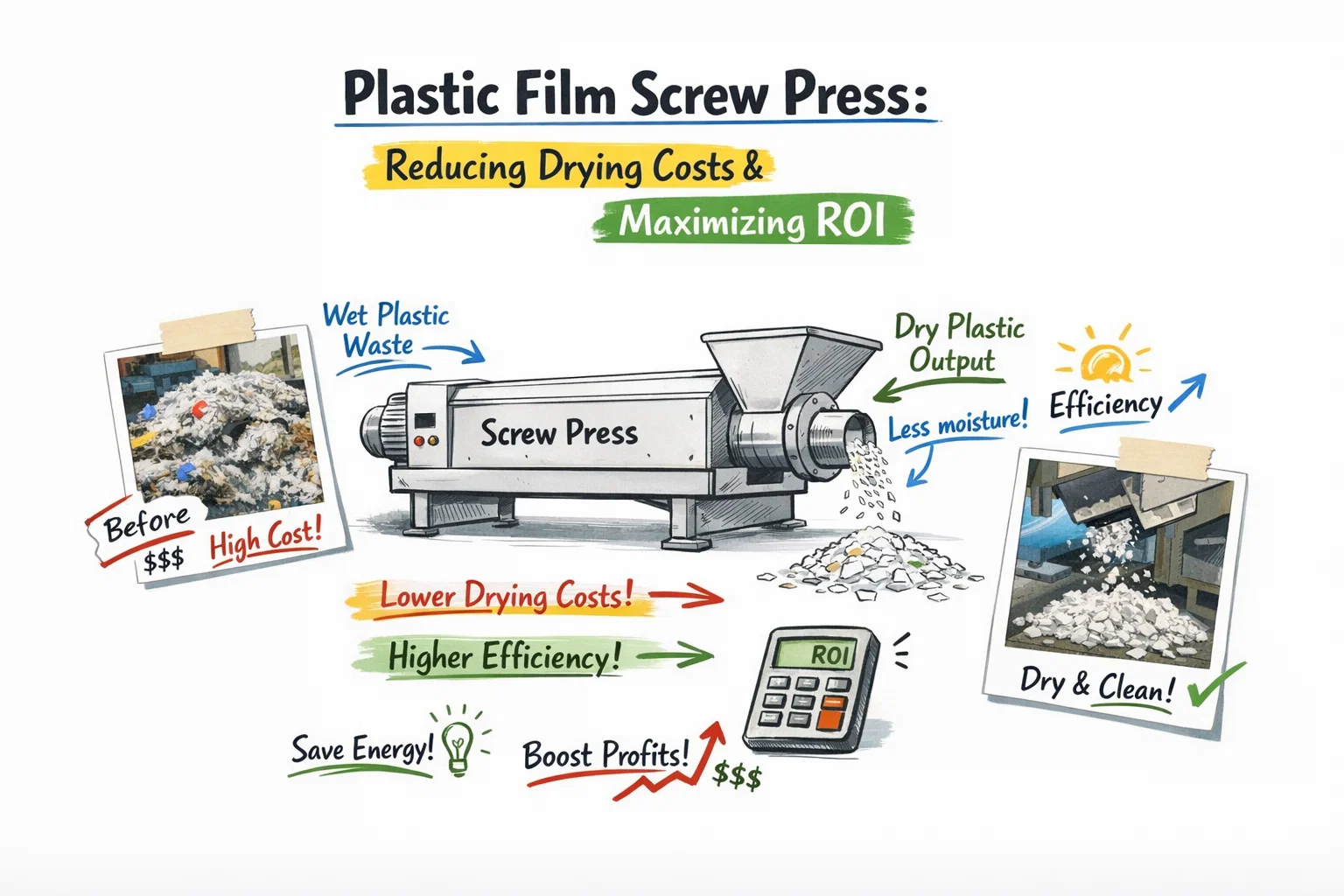

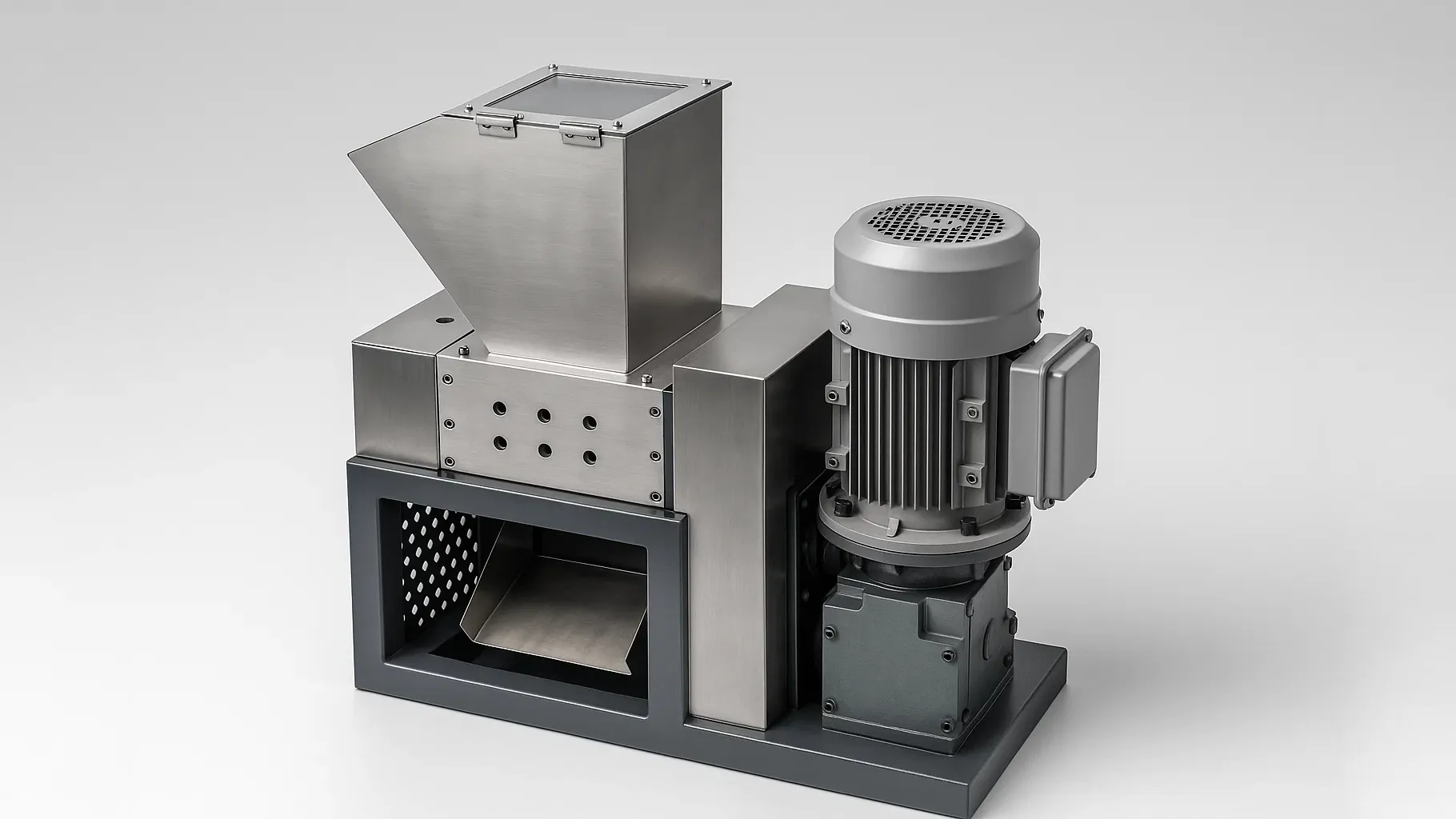

You want to recycle LDPE and PP films profitably. A full recycling line lets you take dirty plastic film waste, clean it thoroughly, and turn it into pellets that packaging plants and manufacturers pay good money for. At Rumtoo, w...