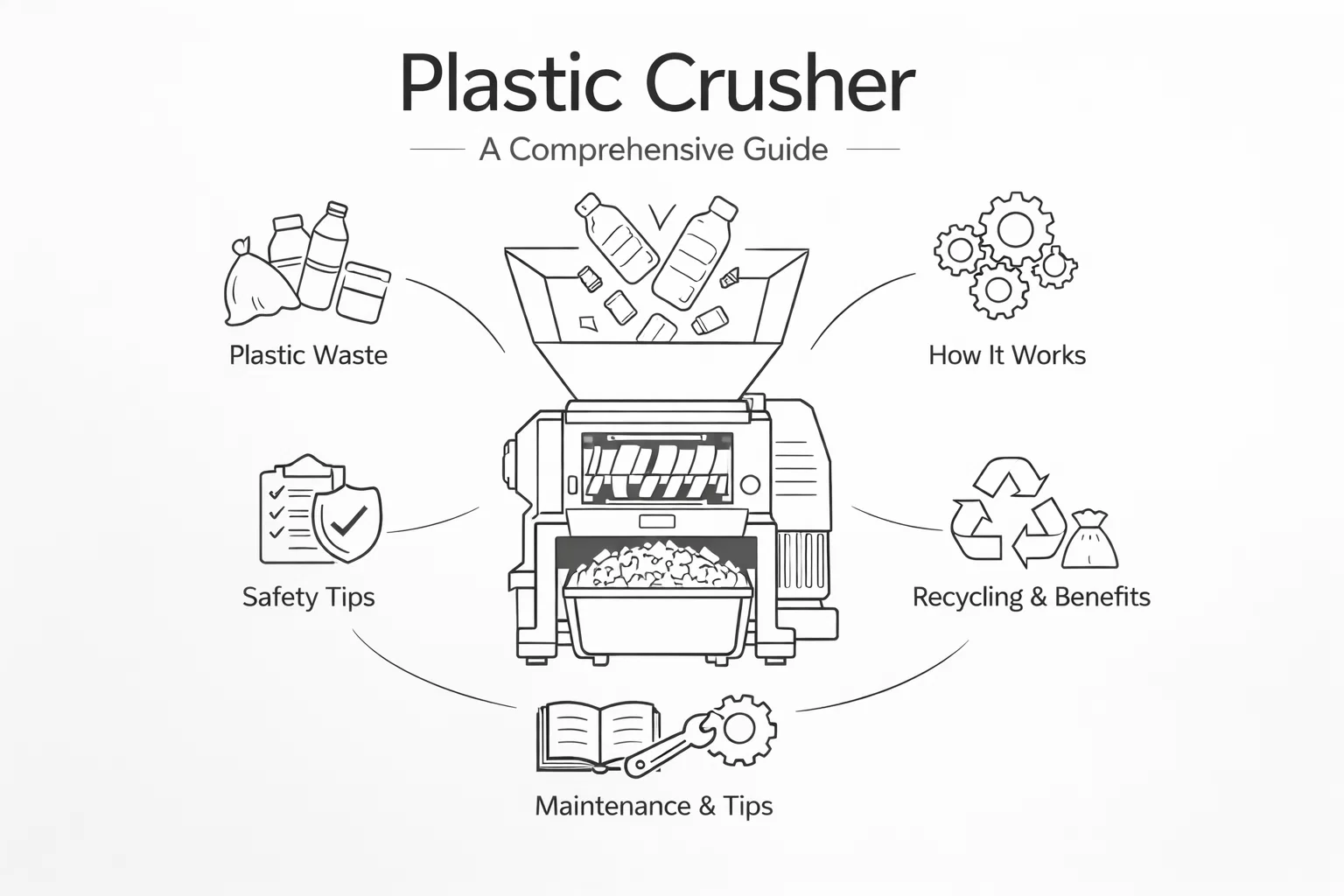

Plastic crushers—often called granulators in international markets—are essential machines in recycling operations, converting bulky plastic waste into uniform flakes ready for washing and peletleme.[1] For plant managers and procurement teams evaluating size-reduction equipment, understanding crusher mechanics, types, and maintenance requirements directly impacts throughput, material quality, and return on investment.

Operating Principles of Plastic Crushers

Plastic crushers use a straightforward but effective cutting mechanism. Hardened steel blades mounted on a high-speed rotor (typically 400-600 RPM) spin inside a cutting chamber lined with stationary knives.[2] As material enters the chamber, rotating blades shear it against fixed knives through precise cutting action. A perforated screen at the chamber bottom controls final particle size—only material small enough to pass through the screen openings (typically 10-100mm) exits the crusher.[3]

The dominant physical action is shearing when blades are sharp and clearances tight. Dull blades shift the process toward tearing and compression, reducing efficiency and increasing energy consumption.[4]

Crusher Types and Blade Configurations

Three primary blade arrangements address different material characteristics:

Double Scissor Cut (Parallel Blade): Rotor and stationary blades align at a slight angle, maintaining consistent cutting gaps. This configuration generates minimal heat, consumes less power, and produces clean cuts. Best suited for bottles, rigid containers, and general-purpose crushing.[5]

V-Type Rotor: Blades mount in a V-pattern, concentrating material toward the chamber center even as cutting edges wear. The V-shape prevents material from escaping to the sides and maintains cutting efficiency longer. Recommended for thick-walled parts and harder engineering plastics.[5]

Helical Rotor: Blades arrange in a spiral pattern within an enclosed rotor body. This heavy-duty design handles thick cross-sections, pipes, and profiles that would jam other configurations. For processing long plastic pipes and profiles, specialized horizontal crushers offer superior performance.[5]

Blade material significantly affects performance and operating costs. Premium D2/SKD11 tool steel provides the hardness and wear resistance required for consistent cutting over extended production runs.[1]

Factors Determining Throughput

Crusher capacity depends on multiple interrelated variables:

Material properties present the primary constraint. Soft polymers like PE and PP cut faster than tough engineering resins such as ABS, nylon, and polycarbonate. Post-consumer material with dirt and labels processes more slowly than clean production scrap.[5]

Cutting chamber dimensions and blade width directly control how much material the crusher can accept per cycle. A 1000mm-wide cutting chamber processes significantly more volume than a 600mm unit.[1]

Motor gücü determines rotor speed under load. Undersized motors bog down when fed aggressively, reducing throughput. Heavy-duty crushers specify 55-110kW motors to maintain speed through tough materials.[1]

Screen aperture size creates the most direct trade-off: smaller holes produce finer output but require longer residence time in the cutting chamber. An 8mm screen delivers granules suitable for injection molding regrind; a 95mm screen produces flakes for washing lines.[6]

Wet Granulation Technology

Wet crushers inject water into the cutting chamber during operation, delivering three performance advantages for film and bottle recycling:[5]

Partial washing begins immediately, flushing away loose dirt and reducing contamination load on downstream washing equipment.

Lubrication and cooling between blade surfaces reduces friction, controlling temperature rise that would otherwise soften thermoplastics and accelerate blade wear.

Extended blade life results from reduced cutting temperatures and better chip evacuation. Facilities running wet crushers report 40-60% longer intervals between blade sharpening.[1]

Wet crushers integrate into çamaşır ipleri for PET bottles, HDPE containers, and agricultural film where moisture is already present and water treatment systems handle the discharge. For dedicated wet crushing applications, consider a ıslak plastik kırıcı designed specifically for this purpose.[7]

Operational Guidelines for Maximum Efficiency

Follow these practices to prevent jams, reduce wear, and maintain consistent output:[5]

- Never start with material in the cutting chamber—trapped material can jam the rotor or overload the motor during startup

- Feed material continuously at a steady rate; batch feeding causes motor surges and uneven cutting

- Keep metal, stones, and oversized lumps out of the feed stream using pre-screening or metal detection

- Empty collection bins before they fill—backed-up material can force its way into bearings and motors

- Run the crusher before feeding and continue running after feeding stops to clear the chamber completely

- Stop the blower only after stopping the crusher to prevent material backup in discharge piping

Preventive Maintenance Requirements

Crusher reliability depends on disciplined maintenance schedules:[8]

Blade management represents the single most critical maintenance task. Sharp blades cut cleanly, producing uniform flakes with minimal fines and dust. Dull blades tear material, creating ragged edges, increasing power consumption, and generating heat. Establish a blade rotation schedule based on tonnage processed—typically every 40-80 operating hours depending on material abrasiveness. Keep spare blade sets on hand to minimize changeover time.[9]

Screen inspection should occur at each shift change. Clogged screens restrict material flow, causing buildup in the cutting chamber that leads to overheating and melted plastic. Brush screens clean with wire brushes between blade changes. Rotate screens 180° periodically to distribute wear evenly across the perforation pattern.[5]

Bearing and motor lubrication follows manufacturer-specified intervals. Check gearbox oil levels weekly and change oil annually or per hour-meter schedule. Motor bearings typically require regreasing every 2000-3000 hours.[10]

Foreign object removal protects against catastrophic damage. Even small metal pieces can chip carbide blade edges or crack the rotor. A damaged rotor requires costly repairs and extended downtime.[5]

Plant managers report that proactive maintenance reduces unplanned downtime by 70-80% compared to run-to-failure approaches.[11]

Selecting the Right Crusher

Material type, feed size, required output particle size, and desired throughput determine appropriate crusher specifications. Small crushers with 22-30kW motors handle 200-300 kg/hr for beside-the-press regrind recovery. Heavy-duty units with 90-110kW motors process 900-1200 kg/hr of rigid containers or thick-walled parts.[1]

For facilities processing mixed materials, specify blade holders that allow quick changeover between flat, V-type, and claw blade configurations without replacing the entire rotor.[12]

Wet crusher capability adds 15-25% to equipment cost but delivers immediate ROI in washing line applications through reduced blade wear and improved flake cleanliness.

For detailed specifications and to explore our complete range of plastic crusher models, visit our plastic crusher product page.