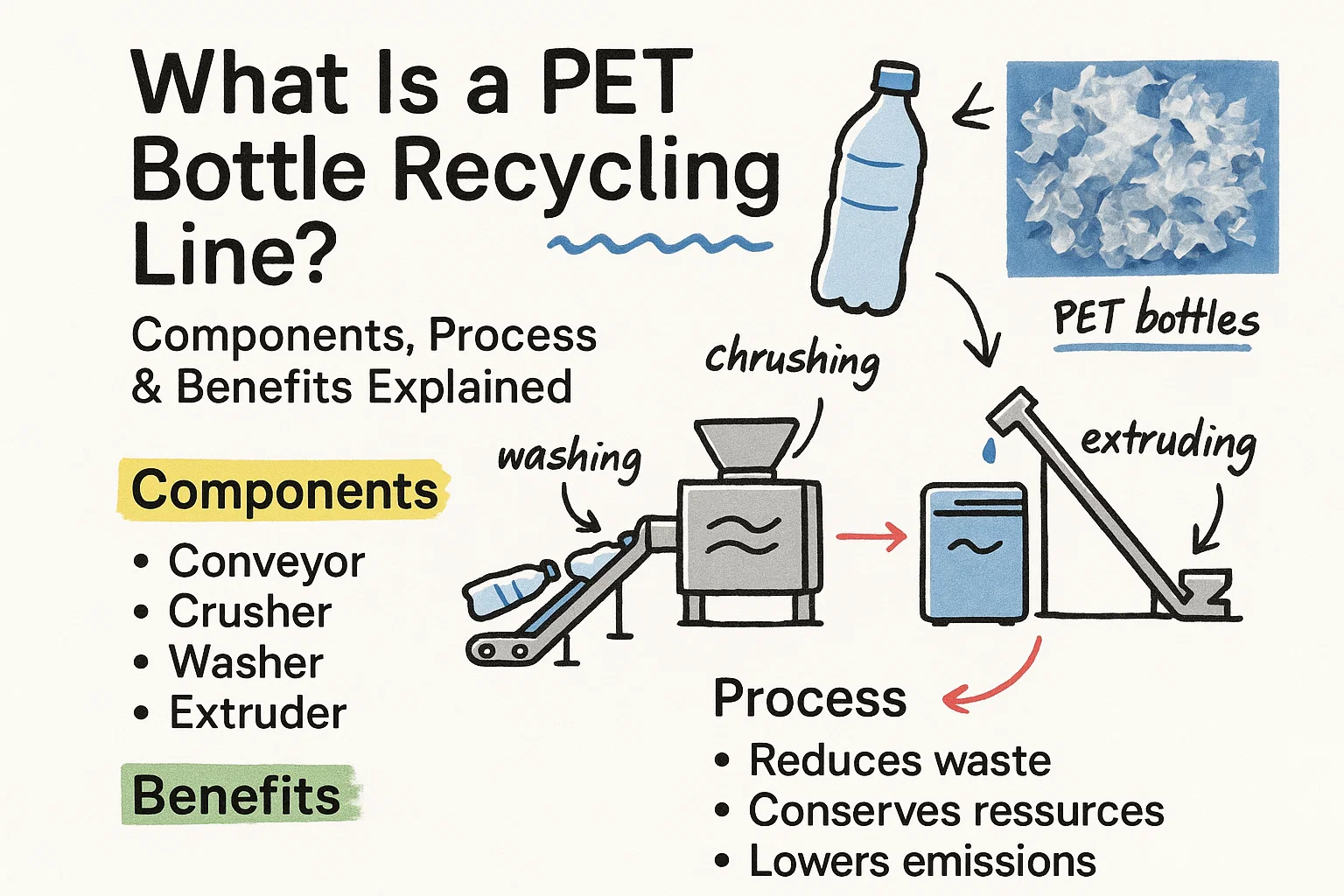

PET Bottle Recycling Line: Complete Guide

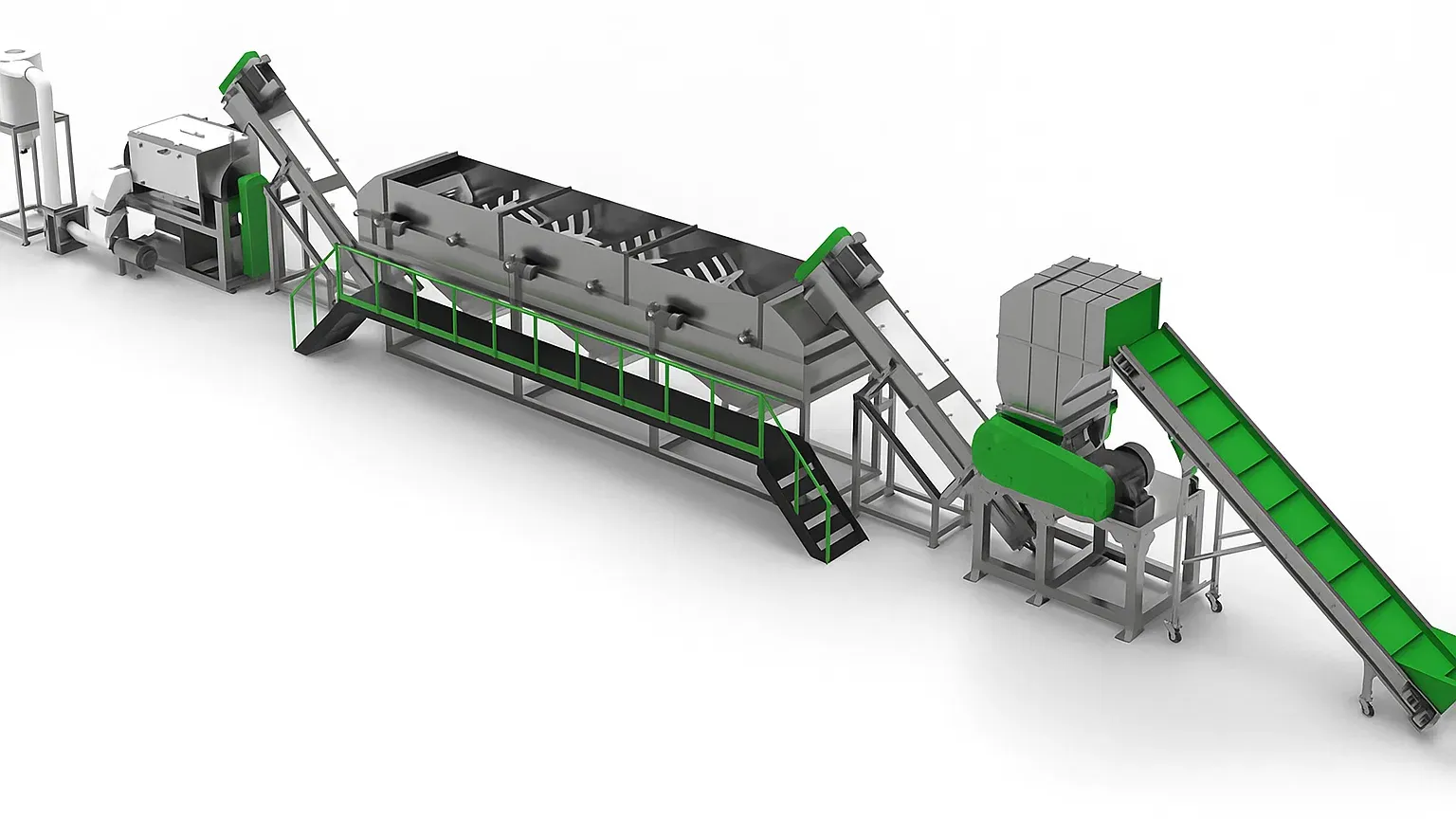

PET Bottle Recycling Lines transform post-consumer waste into valuable resources at an unprecedented scale. With billions of plastic bottles entering the waste stream annually, efficient recycling technology is key to reducing lan...