Our specialized extruded plastic granulator machines are engineered for granulating long pieces of rigid plastics for recycling such as pipes, sheets, boards, and other extruded profiles. It’s an optimal solution for crushing PP-R, PE, and PVC pipes that are challenging to insert into most plastic granulators.

Not looking to granulate long, extruded plastics? Check out our standard plastic granulator machines for granulating plastic bottles, plastic films, and other rigid plastics.

Working Principle

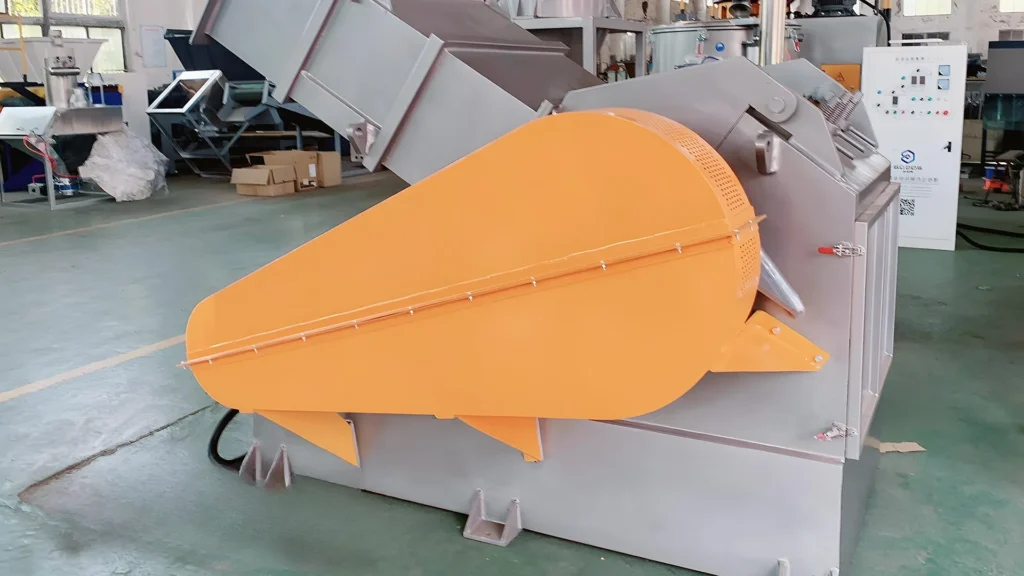

This unusual shaped plastic granulator machine has an extended inlet set at a comfortable angle for operators to conveniently and safely insert long pieces of plastic for granulating. Its sturdy, stepped clamping blade design inside the cutting chamber allows this granulator to break and cut hard plastic material with high durability.

At the core of our extended plastic granulators is an open rotor attached with exceptionally sturdy 9CrSi blades in a stepped array for maximum shearing strength and crushing efficiency. As the rotor spins between 480 to 650 rpm (depending on model), the rotor blades come in contact with stationary blades inside the cutting chamber resulting in the extruded plastic being continuously granulated until it is small enough to pass through a screen filter.

The removable filter screen has many holes between 8-10 mm at the bottom of the granulator. The filter is designed to be easily disassembled and assembled for easy cleaning. Once the plastic is small enough, it will fall through this screen filter and be extracted to the next recycling machine using a powerful blower motor.

Additional Images

Inquirie Now

Warranty

All recycling machines come with a 1-year limited warranty.

To get the latest prices and lead times, send us a message using the form below.