Industrial Single Shaft Shredder for Plastic, Wood & More

High versatility, high throughput, and consistent output size with low noise and dust.

New to shredding? Read our Guide to Plastic Shredder Machines for Recycling to compare configurations and applications.

Explore Our Plastic Shredders

Browse our full lineup of industrial shredders below — from compact units to heavy‑duty systems, including single/dual‑shaft and integrated shredder‑granulator solutions. High torque, low dust, consistent output. Tell us your material and capacity, and we’ll recommend the right model.

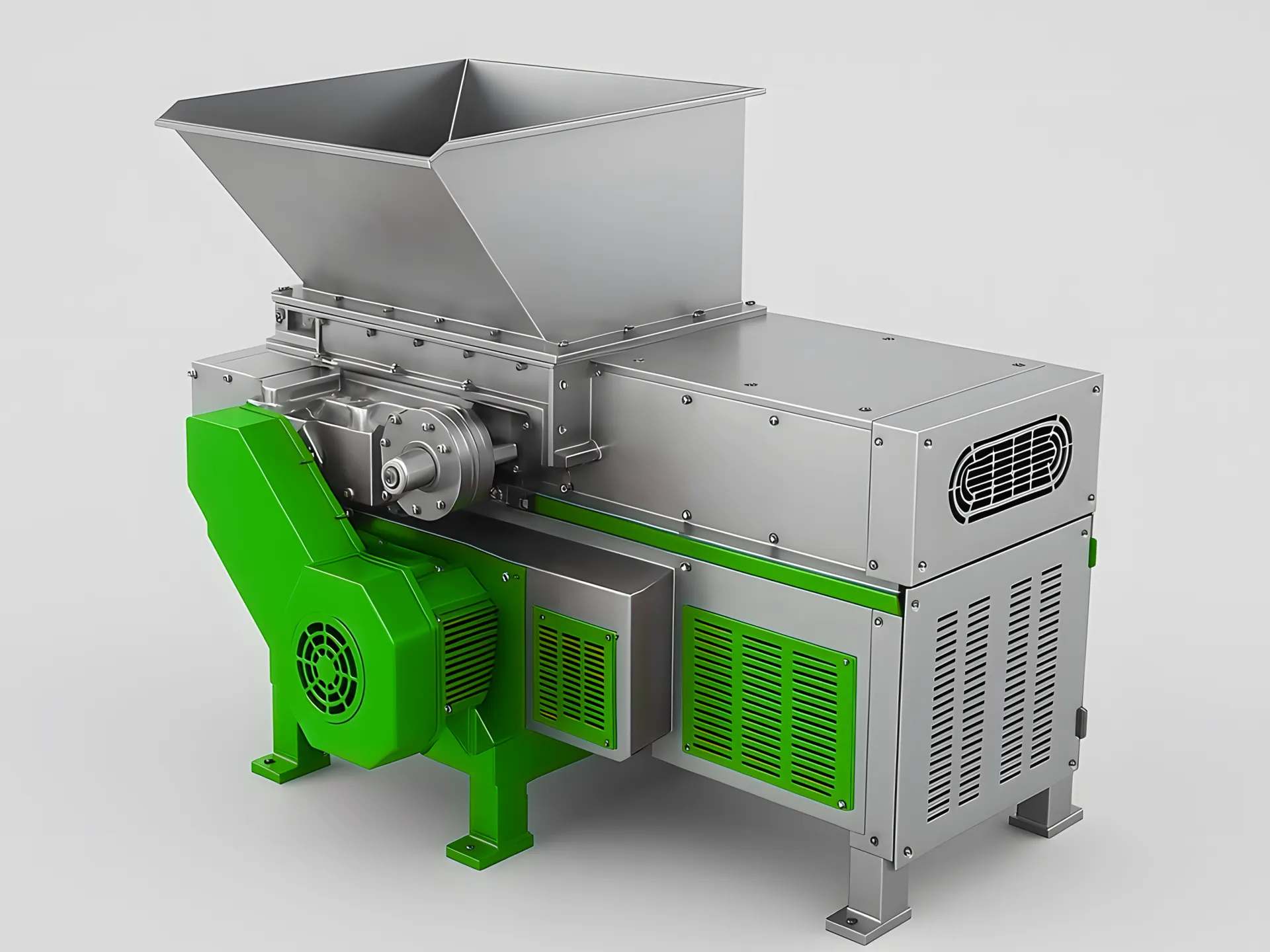

Standard Single-Shaft Shredder

Our flagship shredder: high torque, controllable output, and proven reliability across plastics from films to blocks.

READ MORE →

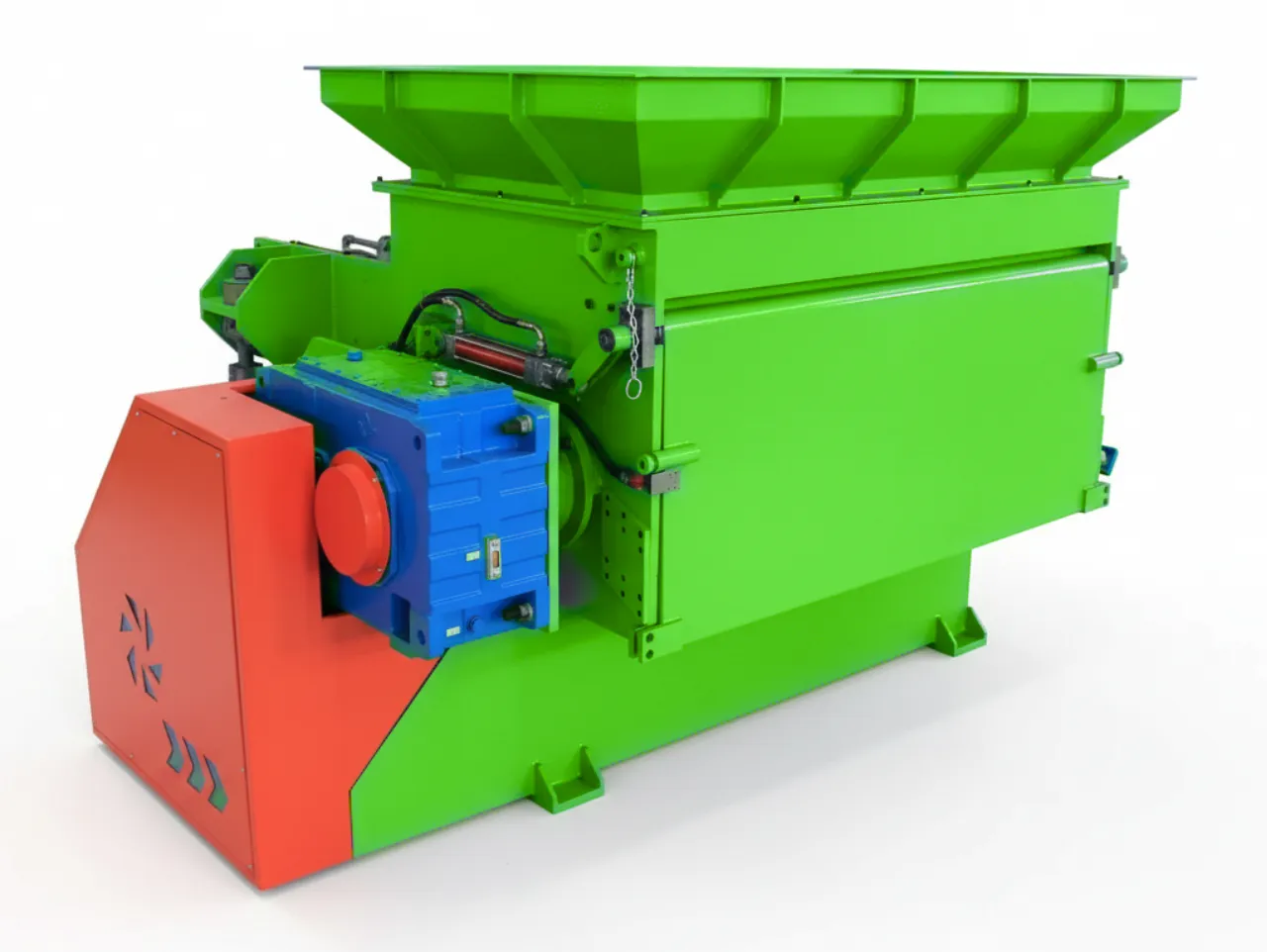

Double Shaft Shredder

Heavy-duty twin shafts eat bulky, tough waste with low speed, high torque, and minimal dust.

READ MORE →

Integrated Shredder & Granulator

One compact line handles both shredding and granulating—less footprint, fewer transfers, lower costs.

READ MORE →

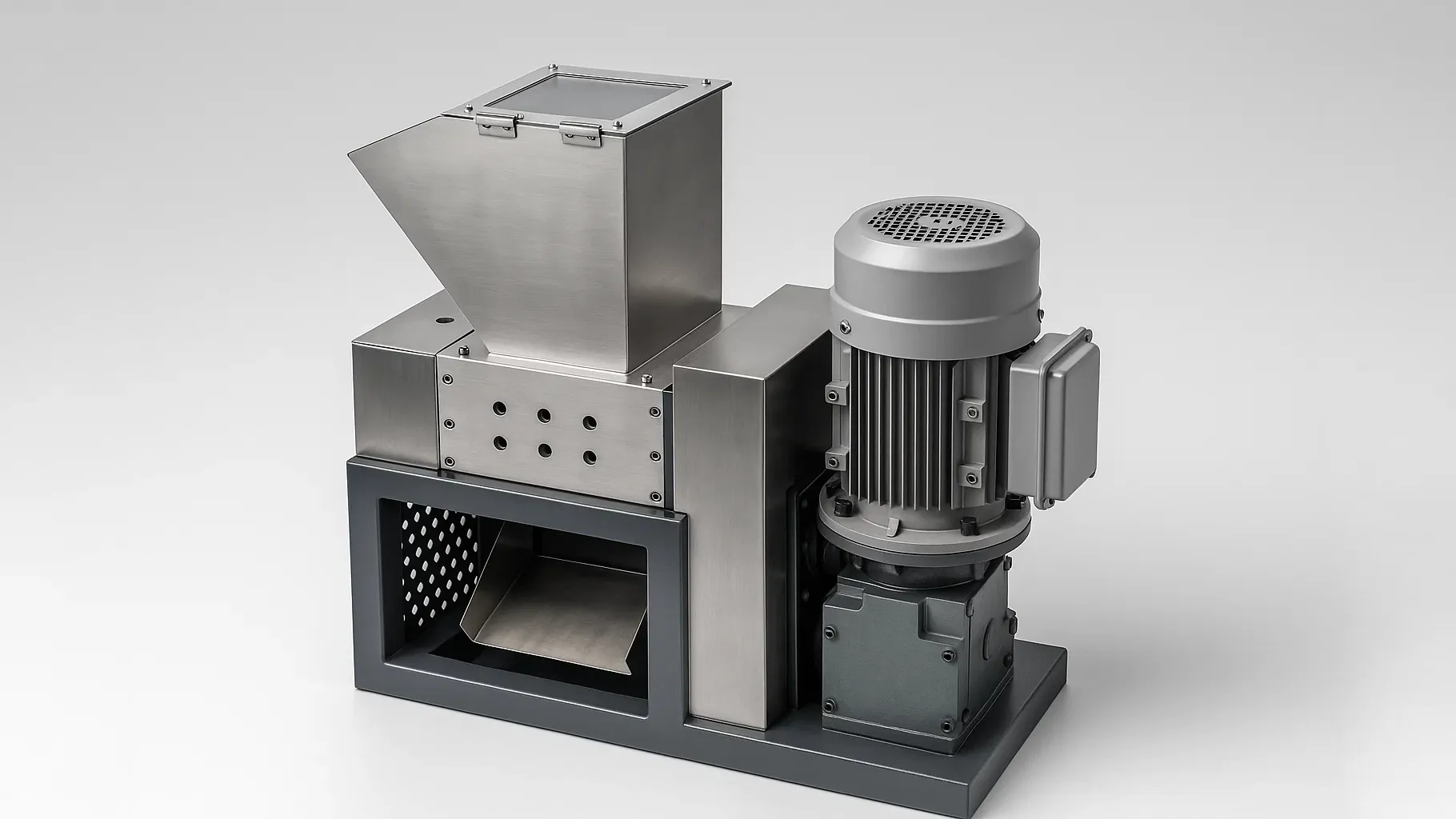

MINI COMPACT SHREDDER

Small footprint, plug-and-run performance—perfect for labs, startups, and on‑site trials.

READ MORE →

Industrial HDPE Pipe Shredder

Deep-V hopper and high torque for long, thick-walled pipes—no pre-cutting needed.

READ MORE →

Film & Woven Bag Shredder

Anti‑wrapping rotor and optimized knife spacing keep flexible materials flowing and output uniform.

READ MORE →

Rigid Plastic Shredder

Designed for thick, hard parts—stable throughput, clean cuts, and long knife life.

READ MORE →

Rubber Tire & Plastic Shredder

Built to tackle steel-belted tires and bulky plastics with auto‑reverse protection.

READ MORE →

Textile & Fibre Shredder

Anti‑wrap design maintains steady feed on fibrous, fluffy materials for consistent output.

READ MORE →

Waste Wood Shredder

Handles pallets and biomass with replaceable liners and options for dust control.

READ MORE →

Hydraulic Drawer Shredder

Quick‑access hydraulic screen drawer slashes downtime for cleaning and maintenance.

READ MORE →

Single-Shaft Shredder with Swing Arm

Oscillating swing arm applies even pressure on light or hollow parts for smooth feeding and steady throughput.

READ MORE →Solutions by Material

Click a material to explore the recommended equipment and configuration.

For Plastic Film & Woven Bags

Anti-wrapping- Soft and elastic, easy to wrap around the rotor.

- Low throughput with conventional shredders.

- V-profile rotor with film-specific knife spacing.

- Anti-wrapping knife seats and guide ribs.

- Optional nip-roll or conveyor feeding.

For Plastic Pipes & Profiles

Deep V Hopper- Bulky, thick-walled, hard to feed.

- Extra-deep V hopper for long parts.

- Heavy-duty hydraulic pusher.

- Reinforced rotor and bearings.

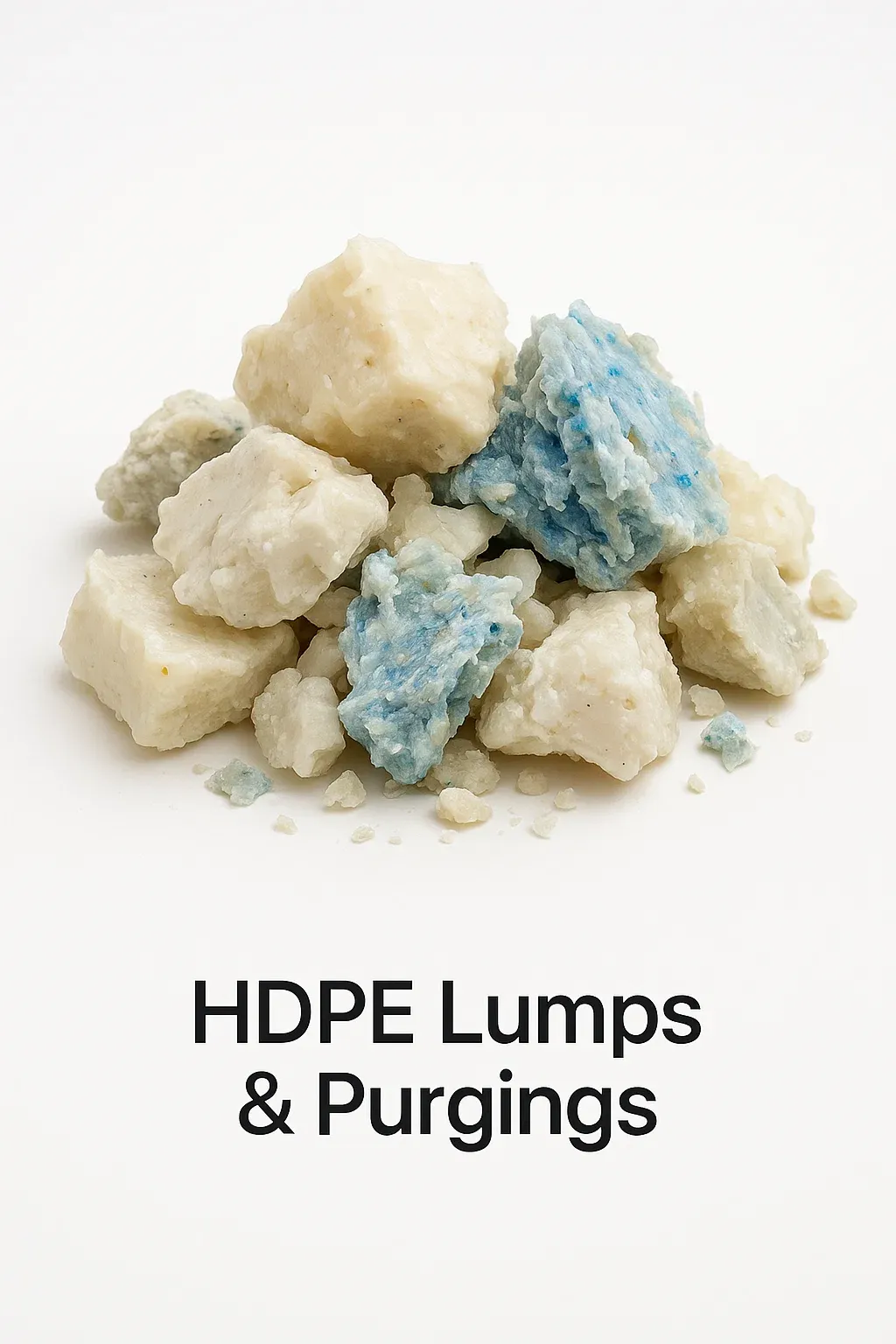

For HDPE Lumps & Purgings

High Torque- Very hard and heavy; high shock load.

- Thick rotor, wear-resistant knives.

- High-torque gearbox.

- Auto-reverse and overload protection.

For Wood Pallets & Biomass

Optional Dust Control- Nails and contaminants; dust and chips.

- Wear liners, replaceable screens.

- Magnetic separation and dust extraction.

For Tires

Wire & Steel Handling- Steel wire and tough rubber increase wear.

- Bulky shapes require aggressive infeed control.

- High‑torque drive with overload protection.

- Wear liners and hardened knife materials.

- Optional wire separation downstream.

For Textile & Carpet

Anti‑Wrap Feeding- Fibrous materials tend to wrap and bridge.

- Light, fluffy feed reduces throughput.

- V‑rotor with anti‑wrap knife seats.

- Nip‑roll or conveyor assisted feeding.

- Optional dust control for cleaner operation.

Watch It Shred

Short demo across films, pipes, and lumps.

How It Works

From feed to uniform output in three simple steps.

Feeding

Load long, bulky, or flexible materials via deep‑V hopper, conveyor, or hydraulic pusher. Safety interlocks and guided infeed keep operation smooth and secure.

Shredding

High‑torque rotor shears against fixed knives to cut efficiently with low dust. PLC logic monitors current and triggers auto‑reverse to clear jams and protect the drivetrain.

Discharge & Size Control

Material passes through a replaceable screen for precise, uniform size. Air conveying or a discharge conveyor transfers chips to the next step with minimal handling.

Key Features & Options

Siemens Motor

High-efficiency motors for reliable power delivery.

PLC & Auto-Reverse

Overload protection and automation.

Alloy Steel Knives

Rotatable edges for long service life.

Replaceable Screens

20–100mm screen sizes for precise control.

Dust Control

Optional extraction for clean operation.

Feeding Systems

Conveyors, nip-rolls, or loaders.

Models & Specifications

| Spec | Unit | RTM-600-SH | RTM-800-SH | RTM-1000-SH | RTM-1200-SH |

|---|---|---|---|---|---|

| Outer size | mm | 2150×1420×1800 | 3050×1620×2150 | 3350×1950×2800 | 3350×1950×2800 |

| Inlet size | mm | 915×600 | 1350×800 | 1450×1000 | 1450×1200 |

| Rotation diameter | mm | 300 | 355 | 355/400 | 415 |

| Rotation speed | rpm | 72 | 72 | 72 | 72 |

| Screen aperture | mm | 40–60 | 40–80 | 40–100 | 40–100 |

| Moving blade qty | pcs | 30 | 44 | 56 | 68 |

| Fixed blade qty | pcs | 4 | 4 | 4 | 4 |

| Motor power | kW | 22/30 | 37/45 | 55/75 | 75/90 |

| Hydraulic station | kW | 2.2 | 3 | 4 | 5.5 |

| Push range | mm | 600 | 800 | 1000 | 1200 |

| Capacity | kg/h | ≤600 | ≤800 | ≤1000 | ≤1500 |

| Weight | kg | 2300 | 3800 | 4900 | 6500 |

Why Choose Us

Proven in the Field

Installed base across plastics, wood, and recycling plants.

Engineering Support

Material testing, line design, commissioning, and training.

Quality Assurance

Heavy-duty build, branded electrics, and strict QC.

Frequently Asked Questions

Yes. The PLC monitors current and triggers auto-reverse to clear jams, protecting knives and the gearbox.

Depends on material. Hardened alloy knives are rotatable (up to four edges) to extend life; regrinding service is available.

Tell us your material, max piece size, desired output size, and capacity (kg/h). We will size the rotor, motor, and screen to match.

Warranty & Installation

We back every machine with strong coverage and hands‑on deployment to keep your line running smoothly from day one.

Comprehensive Warranty

12‑month full parts warranty. Components are guaranteed against defects under normal use and service.

On‑Site Installation

Certified engineers handle installation, commissioning, and operator training for a fast, safe start‑up.

Lifetime Technical Support

Remote diagnostics, quick troubleshooting, and genuine spare parts to minimize downtime over the long term.

Get Your Quote Today

Share your material and capacity — we’ll recommend the right model and options.

Or email us: [email protected] | Contact Rumtoo directly