Eddy Current Magnetic Separator

Efficiently recover non-ferrous metals with advanced Eddy Current Separator. Our innovative eccentric pole system ensures maximum adjustability and recovery, making it ideal for various recycling operations.

View Specifications →

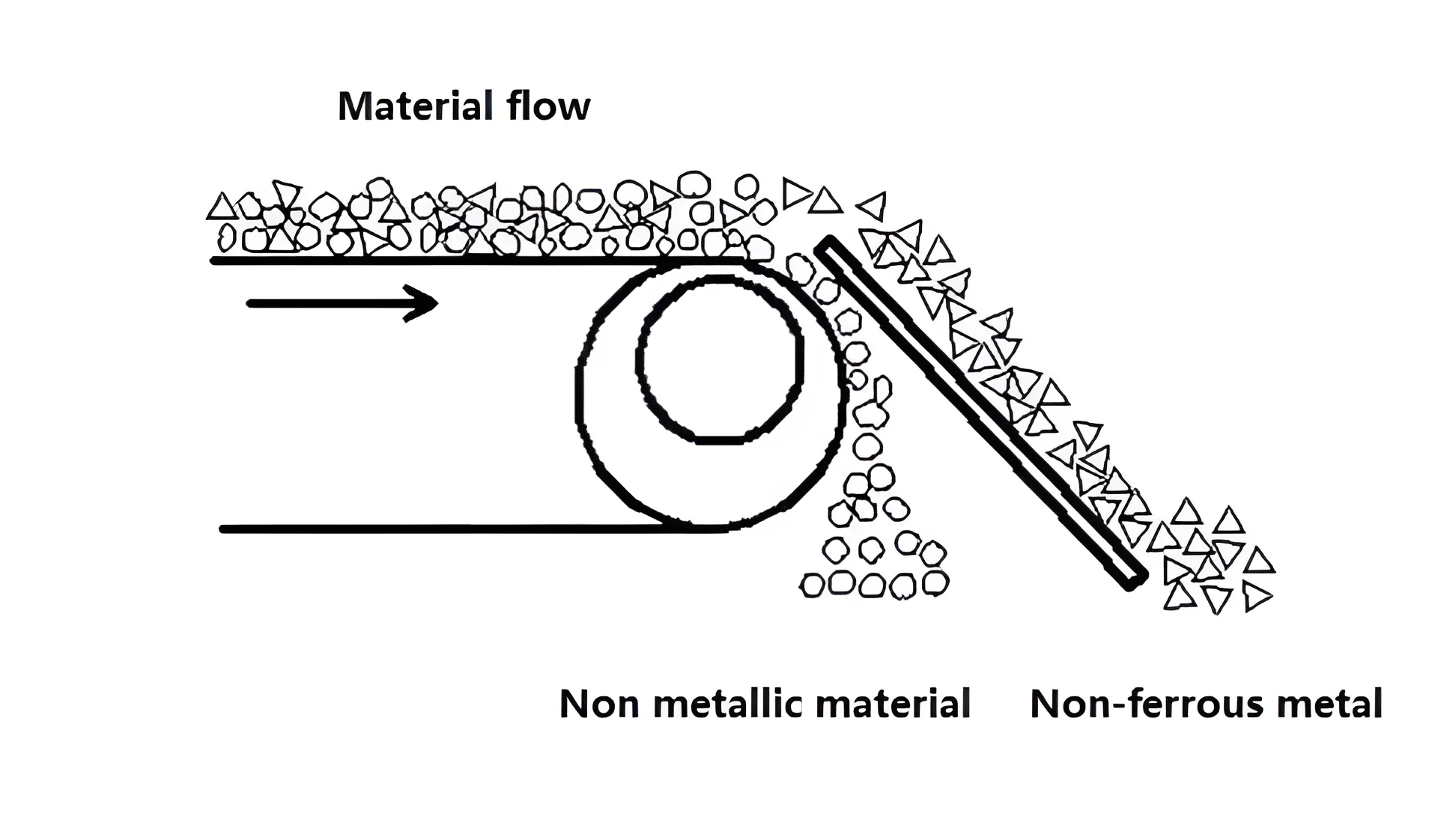

How Eddy Current Separation Works

The eddy current separation process uses electromagnetic induction to separate non-ferrous metals from waste materials through a precise 4-step process.

Material Feed

Mixed materials containing non-ferrous metals are fed onto the conveyor belt at a controlled rate, ensuring optimal separation conditions.

Magnetic Field Generation

High-frequency alternating magnetic fields are generated by the rotating magnetic drum, creating eddy currents in conductive materials.

Eddy Current Induction

Non-ferrous metals develop induced eddy currents, creating their own magnetic fields that oppose the drum's field, causing repulsion.

Material Separation

Repelled non-ferrous metals are ejected further from the drum, while non-conductive materials fall normally, achieving clean separation.

Technical Parameters

- Roller Diameter: 280mm

- Belt Width: 300mm

- Power Supply: 4.5 kW

- Magnetic Field Strength: Adjustable for high recovery rates

- High Separation Efficiency: Achieves up to 96% recovery of non-ferrous metals

- Machine Dimensions: Customizable for different facilities

Key Features

Eccentric and Concentric Pole Systems

Adaptable to different recycling needs, the eccentric pole system maximizes recovery, while the concentric pole system is ideal for fine fractions and materials with less magnetic dust.

High Separation Efficiency

Effectively separates non-ferrous metals with precision, ensuring maximum purity and output quality.

Two-Stage Separation

Optional two-stage separation process for optimized material recovery, particularly in demanding recycling environments.

Low Maintenance and Energy Efficient

The machine is designed for easy operation and minimal maintenance, with low energy consumption for long-term savings.

Equipment in Action

Specifications

| Model | Belt Width (mm) | Roller Diameter (mm) | Belt Speed (m/s) | Magnetic Roller Motor Power (kW) | Belt Motor Power (kW) | Weight (kg) | Length A (mm) | Width B (mm) | Height C (mm) |

|---|---|---|---|---|---|---|---|---|---|

| SES-300 | 300 | 280 | 0~2.5 | 2.2 | 0.75 | 760 | 1940 | 1472 | 1075 |

Applications

Aluminum Recycling

Efficient separation of aluminum from waste streams.

Shredder Material

Processes shredder material for effective metal recovery.

Electronic Scrap (WEEE)

Recovers valuable non-ferrous metals from electronic waste.

Glass and Plastics

Separation of non-ferrous metals in glass, plastic, and wood recycling applications.

Warranty & Installation

1-Year Limited Warranty

All our recycling machinery comes with a limited warranty, ensuring peace of mind with your purchase.

Expert Installation Support

We offer installation packages where our engineers can travel to your facility to guide you through the setup process. All our products can be customized to customer requirements.

Frequently Asked Questions

What materials can the Eddy Current Separator recover?

It recovers non-ferrous metals such as aluminum, copper, brass, and other conductive materials from mixed waste streams.

Is the magnetic pole system adjustable?

Yes. Our eccentric and concentric pole systems allow tuning for different material sizes and recovery targets.

Can the machine be customized to my facility?

Yes. Belt width, machine dimensions, and integration options are customizable to your process layout.

What maintenance is required?

Regular inspection of belts, bearings, and cleaning of the separation area maintains peak performance. Service schedules vary by usage.

Do you provide installation and training?

Yes. We offer installation packages and on-site guidance by experienced engineers to ensure proper setup and operation.