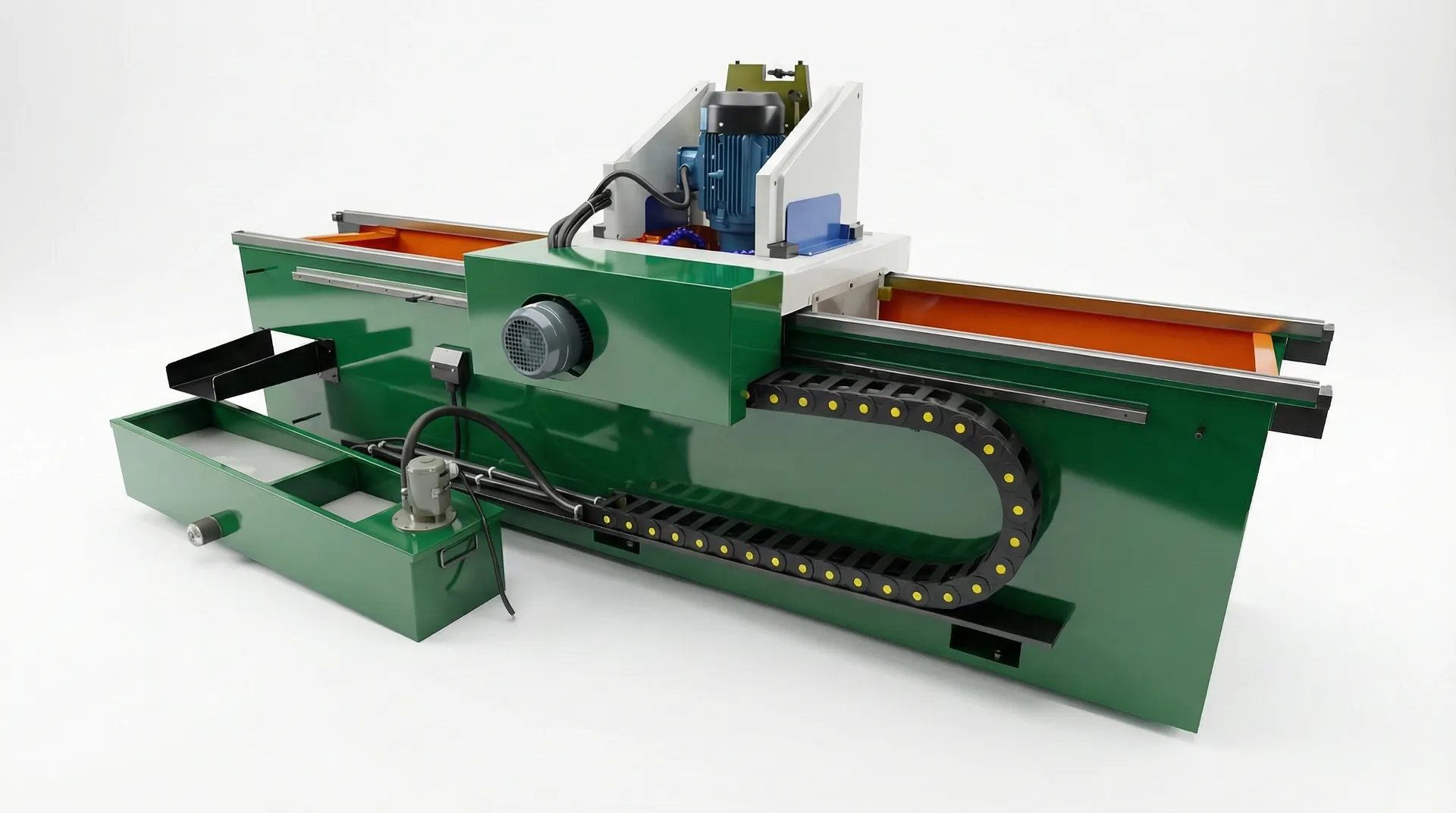

Automatic Knife Grinder

Precision, durability, and stable sharpening performance for shredder and granulator blades. Built for industrial workshops that require repeatable edge quality and reduced downtime.

- Max grinding size: 1600 x 180 mm

- 0 to 90 degree electromagnetic chuck

- Grinding precision up to 0.03 mm

Key Advantages of Our Industrial Knife Grinder

Electromagnetic Chuck

Powerful magnetic holding with 0 to 90 degree angle adjustment for different blade edge setups.

Intelligent Control

Frequency converter control ensures smooth head travel with adjustable speed range.

Precision Drive

Rack and gear transmission improves consistency compared with standard chain drive designs.

Low Noise Operation

Rigid structure absorbs vibration to maintain quieter running and long service life.

Dual Feed Modes

Automatic and manual feed options support depth adjustment from 0.002 to 0.2 mm.

Easy Maintenance

Quick wheel replacement and straightforward cleaning help reduce maintenance downtime.

Automatic Knife Sharpening Machine Specifications

| Parameter | Value |

|---|---|

| Model | RT-1600 |

| Max Grinding Length x Width | 1600 x 180 mm |

| Chuck Type | Electromagnetic |

| Grinding Angle Adjustment | 0 to 90 degree |

| Grinding Head Power | 6.5 kW |

| Grinding Precision | 0.03 mm or better |

| Grinding Wheel Size | 200 x 100 mm |

| Head Travel Speed | 0 to 20 m/min adjustable |

| Auto Feed Amount | 0.002 to 0.2 mm |

| Weight | Approx. 2800 kg |

Plastic Granulator Blade Grinder Customer Reviews

"This is by far the most reliable knife grinder we have used. Precision is outstanding and support is responsive."

Plant Manager, Greenleaf Recycling USA

"Installation was seamless and blade changeover is now faster than ever. Very stable machine behavior."

Operations Director, EcoBlade GmbH Germany

"Robust, quiet, and easy to operate. We sharpened hundreds of blades with consistent results."

Maintenance Supervisor, Plastics Solutions UK

FAQs About Automatic Knife Sharpening Machines

What is the maximum blade size the automatic knife grinder can sharpen?

The RT-1600 handles up to 1600 mm length and 180 mm width. Larger formats can be customized based on your facility's requirements.

Can the continuous sharpening machine grind different types of industrial blades?

Yes. The electromagnetic chuck is highly versatile, making the machine suitable for plastic granulator blades, wood chipper knives, shear blades, and guillotine knives.

Do you provide installation and training for the knife grinding machine?

Yes. We can provide on-site installation, startup support, and operator training. The machine's intuitive control panel ensures your operators can quickly master the grinding process.

What is the warranty period for your industrial knife grinders?

Our standard warranty covers 12 months, backed by long-term technical support and quick access to consumable spare parts like grinding wheels and precision racks.

Knife Grinder Warranty and Installation

1-Year Limited Warranty

All Rumtoo recycling systems include one-year limited warranty coverage for key machine components.

Expert Installation Support

We provide remote and on-site support for installation, commissioning, and operator training.

Get a Free Quote Today

Contact us for pricing, lead time, or customization details. Our engineering team will respond quickly.

Comments are closed.