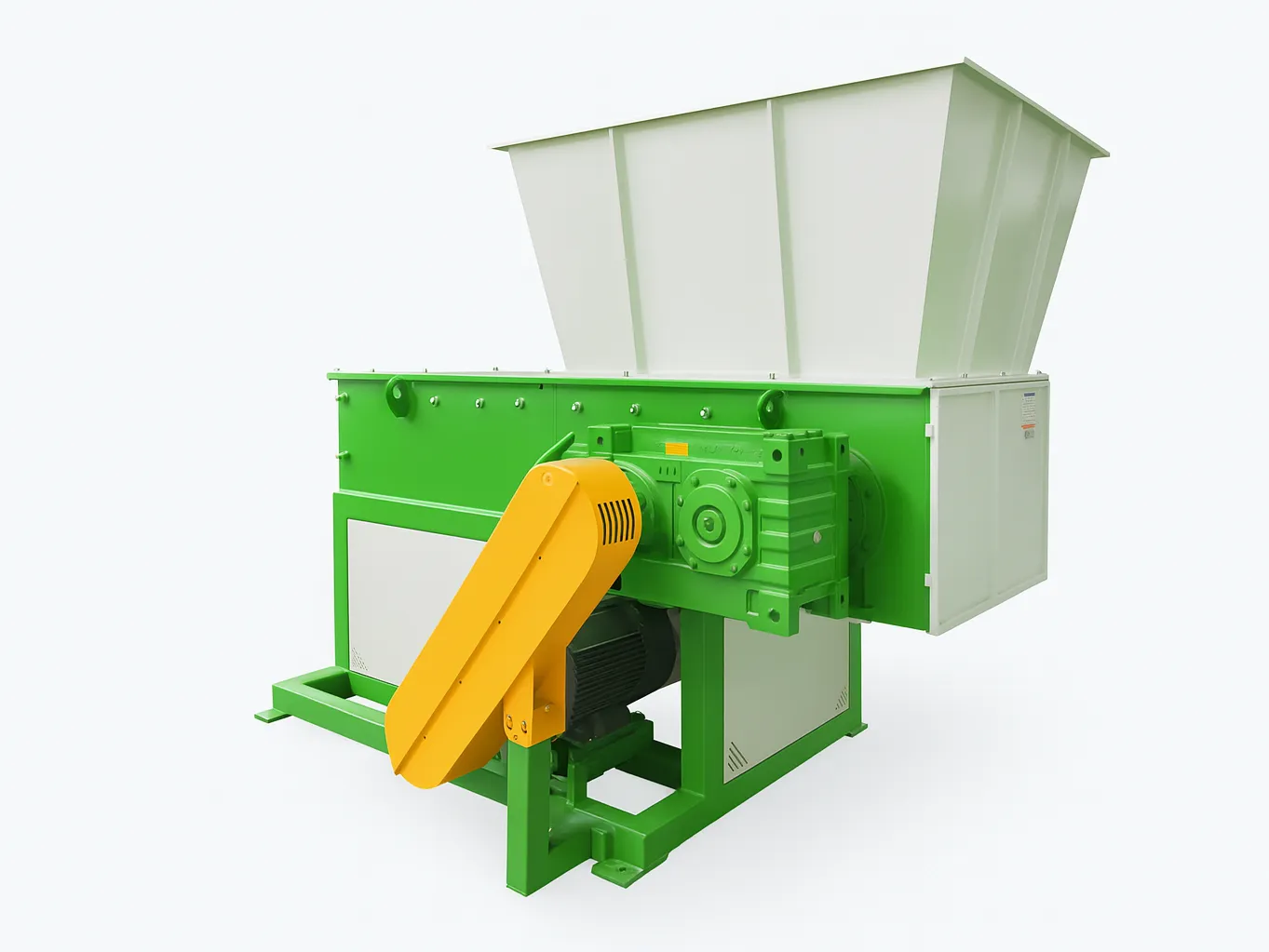

For businesses aiming to enhance their recycling operations, our state-of-the-art waste plastic film shredder is a game-changer. It’s expertly designed to meet the demands of modern, high-volume recycling facilities.

Typical Applications: PE/PP films, agricultural films, industrial packaging, woven bags, and other soft plastics.

Our shredders are equipped with advanced features to deliver superior performance, reliability, and safety.

High-Efficiency Shredding

An innovative material silo design enables a continuous feeding cycle, preventing material jams and ensuring maximum shredding efficiency and throughput.

Enhanced Productivity

The custom-made main shaft features a large rotation diameter, increasing the shredding contact surface for consistently high productivity.

Vibration Reduction

Couplings in the transmission parts reduce vibration, protecting the main shaft and reducer, extending component lifespan, and ensuring no loss of force.

Effective Material Cutting

Fixed knives at the top and bottom of the shaft prevent material entanglement, ensuring clean cuts and significantly reducing maintenance downtime.

PLC Automated Control

An advanced PLC control system automates start, stop, reverse, and overload protection, ensuring stable, safe operation while saving labor costs.

See how our film shredder efficiently processes large volumes of plastic waste without jamming.

| Model | Shaft Diameter (mm) | Moving Knife Qty. | Fixed Knife Qty. | Capacity (kg/h) | Motor (KW) | Feed Mouth (mm) | Weight (kg) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|---|

| RTM-L245 | 300 | 24 | 2 | 400 | 22 | 800 x 1300 | 3600 | 3250x1500x2350 |

| RTM-L306 | 300 | 30 | 2 | 550 | 30 | 900 x 1300 | 4000 | 3250x1750x2350 |

| RTM-L398 | 350 | 39 | 2 | 750 | 45 | 1100 x 1500 | 6000 | 4150x1900x2450 |

| RTM-L3610 | 400 | 36 | 2 | 1200 | 55 | 1300 x 1800 | 8000 | 4700x2550x2650 |

| RTM-L4212 | 400 | 42 | 2 | 1500 | 75 | 1500 x 1900 | 9500 | 5350x2850x2760 |

| RTM-L6416 | 500 | 64 | 4 | 5000 | 132 | 2200 x 2200 | 18000 | 5900x3050x2960 |

This shredder is specifically designed for soft plastics, including PE/PP films, agricultural films, industrial packaging, and woven bags. Its anti-entanglement design makes it ideal for these materials.

The machine features an innovative material silo and feeding system that allows for continuous, unrestricted feeding. Additionally, the PLC control system can automatically reverse the shaft if it detects an overload, clearing potential jams before they occur.

Safety is paramount. The shredder is equipped with a comprehensive PLC control system that includes automatic overload protection, emergency stop buttons, and a robust design that minimizes vibration to protect all components and ensure stable operation.

All our recycling machines include a one-year limited warranty.

Investing in this advanced shredder is a strategic decision for improving your recycling efficiency. To get current pricing and lead times, please submit your request below.