Trial Run of the pet bottle label removal machine Video

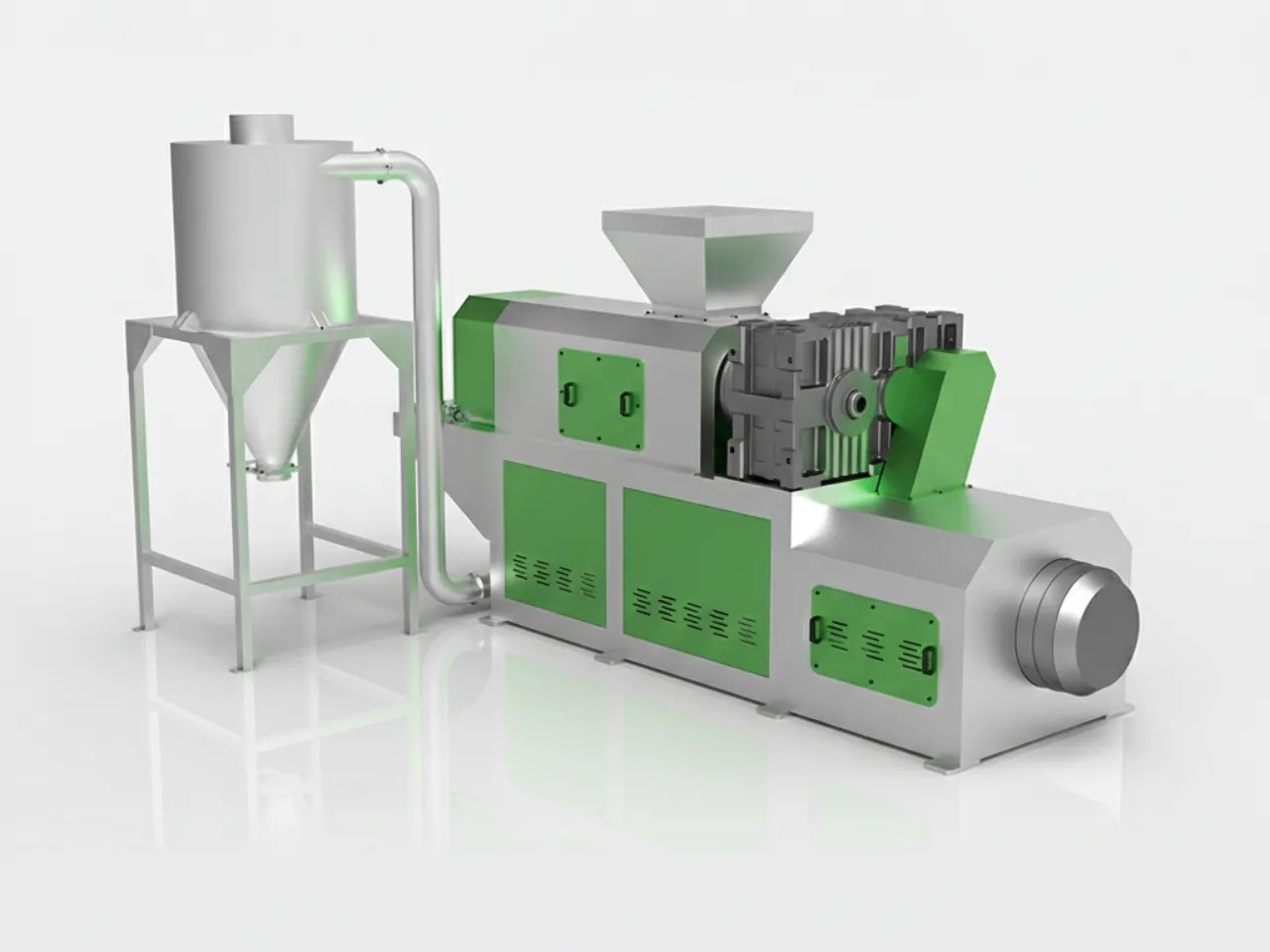

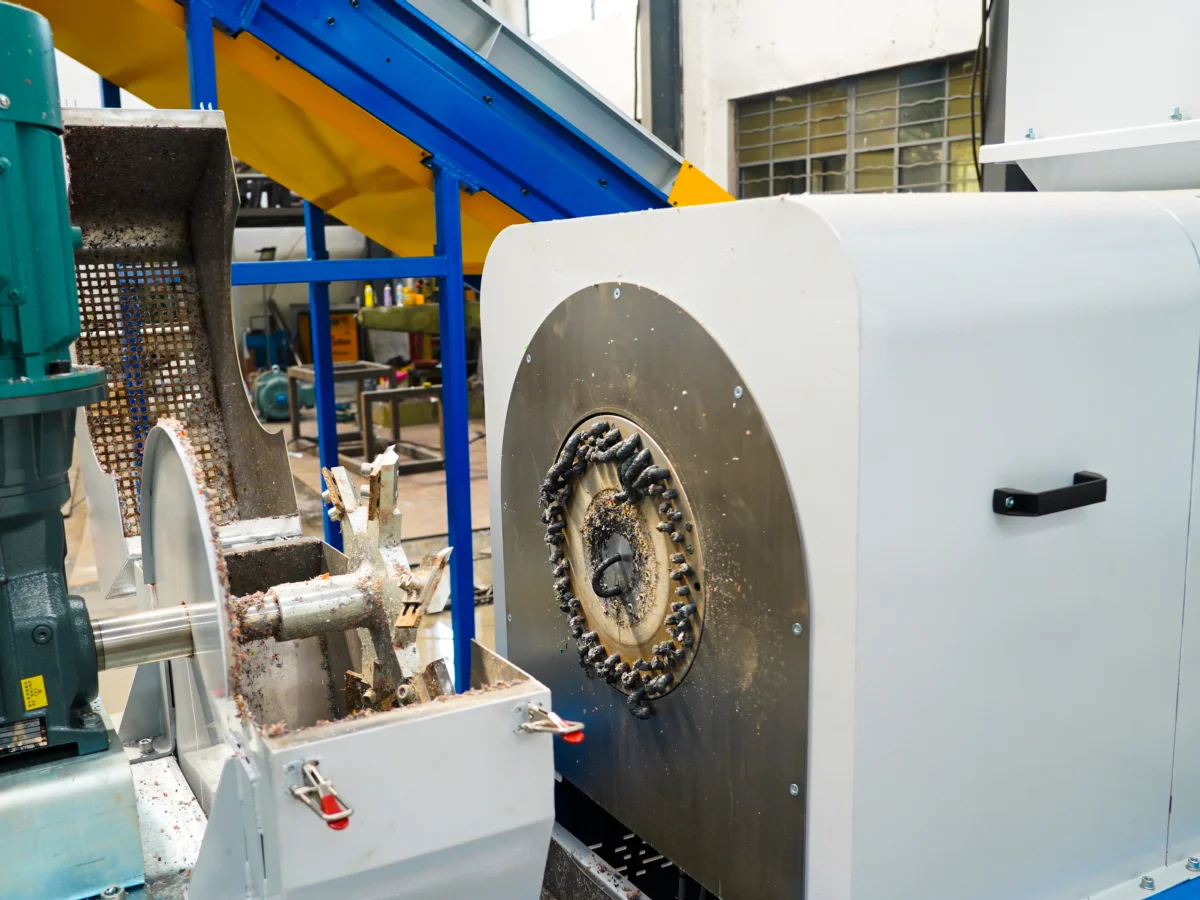

This type of machine is crucial in the recycling process, as it prepares PET bottles for further processing by stripping away labels, which are typically made from different materials and can contaminate the recycling stream. The...

_7.webp)