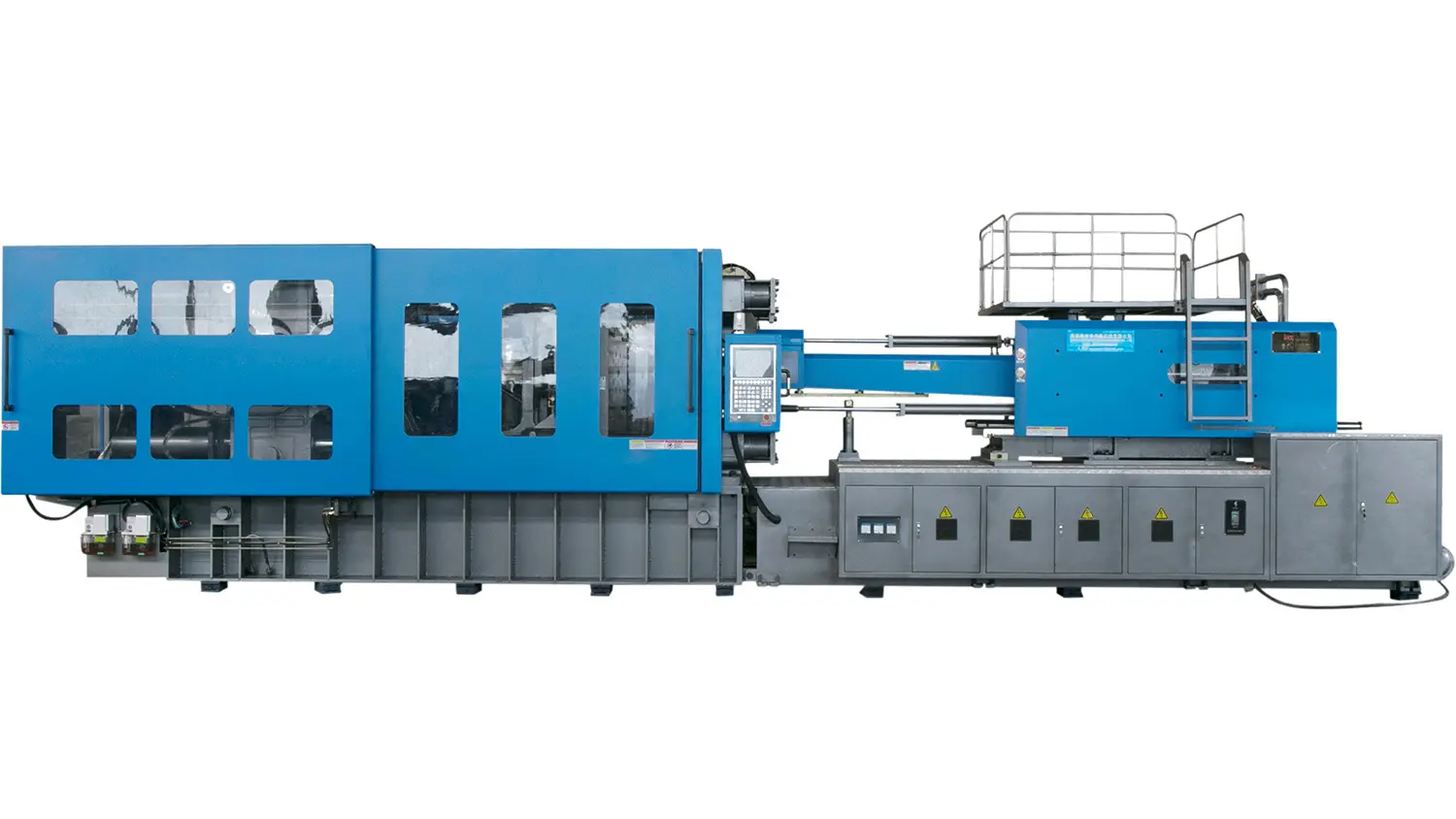

Injection moulding machine adopting europe technology, hydraulic unit adopts proportional pressure and flow control, the pressure and the speed can be adjusted, stable movement curve and gentle shock, the computer is imported from Industry family. The LCD displaying screen with high clarity has Chinese, English, Spanish, Russian, Turkish languages to use. Close-loop PID temperature control with the advantage of high precision. The operating table of the injection moulding machine have two safety, one is machine safety, another is electrical safety, that ensures the operators’ safety.

Remarks

- Injection Molding machine. Produce all kinds of small plastic products, like bottle caps, medical examination containers and almost all the plastic things, we just need to change the mould on the suitable machine.

- Auto loader, used to feed raw material to hopper.

- Dryer with hopper, used to dry wet raw material. It can be installed in injection molding machine directly as a hopper.

- Chiller, used to finalize the device products fully cooling, make products to obtain the final shape and size.

- Crusher, used to crush the waste material for recycle and re-use.

- Mixer, used for color mixing.

- Cooling tower, used to cool the machine by cooling the circulating water to keep it working properly.

Feature

- A new 5-point toggle device offers a stable movement curve and gentle shock.

- High-quality mould platen provides sufficient intensity to prevent deformation under high-pressure clamping.

- Hard chrome-plated tie bars, made of superior alloy, offer high tensile strength and excellent wear and corrosion resistance.

- The moving platen features a wear-resistant guide.

- Clamping stroke is controlled by a transducer.

- Speed and pressure for clamping and opening are managed through multi-step control.

- The ejection device includes dwell, single, multiple, vibration functions.

- Differential high-speed clamping is available.

- Low-pressure mould protection function is included.

- Hydraulic mould height adjustment driven by gear allows both rough and fine operation.

- Safety interlock system combines mechanical and electrical elements for dual security.

- An automatic centralized lubrication system comes with a far pressure detector for convenience

To get the latest prices and lead times, send us a message using the form below.