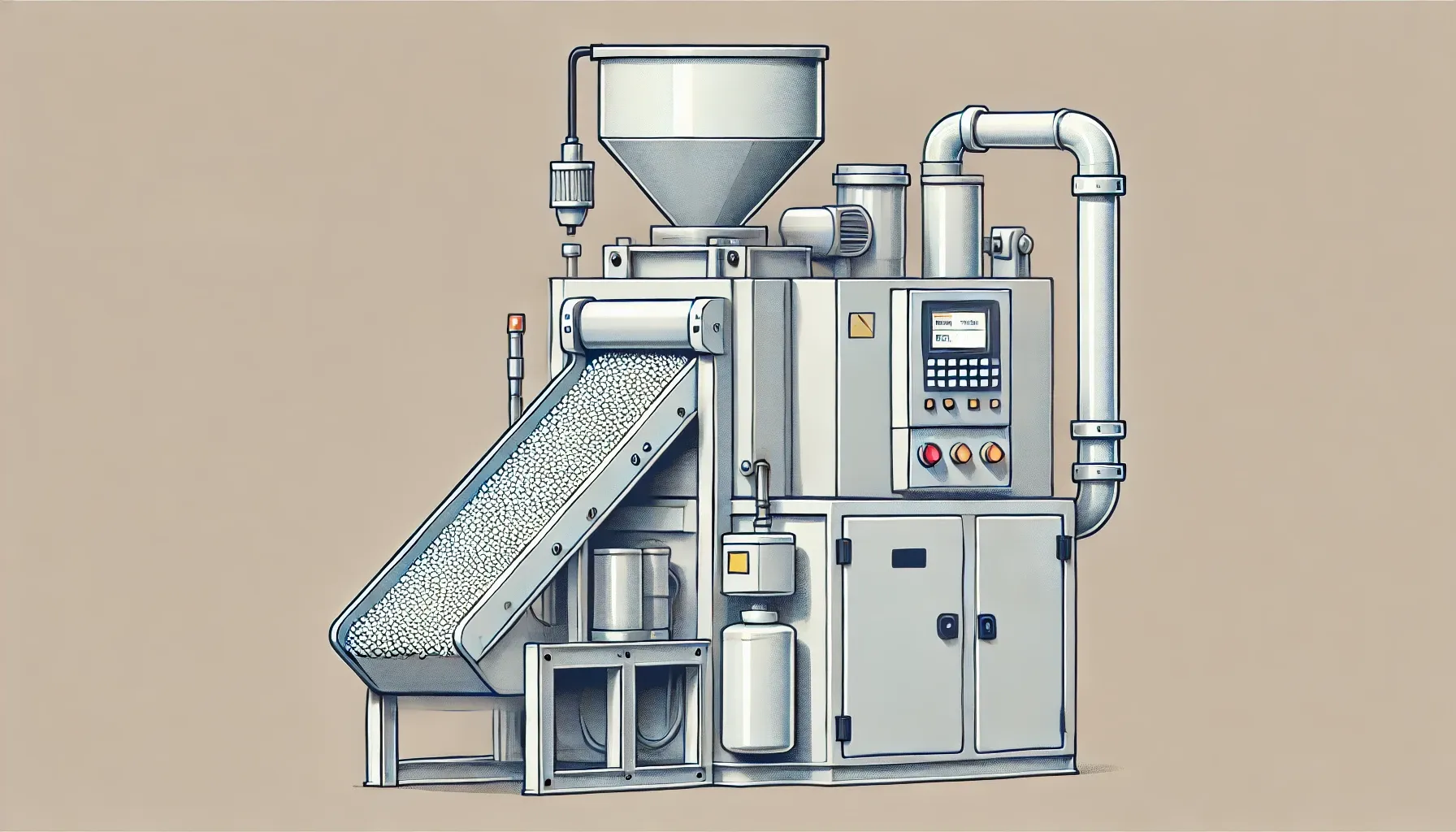

The specific cost of a Plastic Pelletizer Machine varies significantly based on technical configurations, throughput requirements, and component quality. For recycling plant operators and procurement managers, understanding these pricing drivers is essential for calculating ROI. This guide analyzes the primary engineering and market factors that determine the final investment required for industrial pelletizing lines, with insights from Rumtoo’s engineering team.

1. Machine Type and Pelletizing Technology

The method of pelletizing is the most direct influence on equipment cost. Different material characteristics require specific cutting technologies:

- Strand Pelletizing Lines: Often used for processing rigid plastics like PET, ABS, or Nylon. These systems cool extruded strands in a water bath before cutting. They typically offer a lower entry price but require manual stringing during startup.

- Water Ring Pelletizers: Ideal for PE and PP films. The compact design cuts hot pellets directly at the die face, which are then immediately cooled by a rotating water ring. This integrated design is efficient but commands a mid-range price point.

- Underwater Pelletizing Systems: The most capital-intensive option, suitable for high-capacity lines (up to 3000 kg/h) and tacky materials. The complex pressurized water system and specialized die face design justify the higher cost, delivering uniform, spherical pellets.

2. Production Capacity (Throughput Rates)

Price scales directly with the machine’s output capacity, measured in kilograms per hour (kg/h).

- Lab-Scale Units (50–100 kg/h): These smaller extruders use standard motors and smaller screw diameters (e.g., 65mm), resulting in lower costs.

- Industrial Lines (500–1000+ kg/h): High-output machines require heavy-duty gearboxes to handle high torque, larger bimetallic screws (e.g., 150mm+), and high-kilowatt motors (IE3/IE4 efficiency rated). These components significantly increase the manufacturing cost but reduce the cost-per-ton of processed material.

3. Component Quality and Metallurgy

The longevity of a Plastic Pelletizer Machine depends on the quality of its core components, which also dictates the price.

- Screw and Barrel: Standard nitrided steel is cheaper but wears faster. Machines equipped with bimetallic screws (coated with tungsten carbide alloys) cost more but resist abrasion from dirty recycled plastics.

- Gearbox: The gearbox determines the stability of the extruder. High-torque, precision-ground gearboxes from reputable suppliers prevent downtime and are a major cost factor.

- Electrical Components: Panels using components from Siemens, Schneider, or ABB ensure reliability and safety, whereas generic components reduce upfront costs but increase maintenance risks.

4. Automation and Upstream Integration

Modern recycling plants often integrate pelletizers with upstream equipment. A standalone extruder is cheaper than a system integrated with a Plastic Crusher or washing line components.

- Screen Changers: Hydraulic or double-piston screen changers allow for continuous operation without stopping the machine to clean filters. This automation raises the machine price but boosts daily throughput.

- Intelligent Controls: PLC systems spread across the line for temperature synchronization and pressure monitoring add engineering value and cost compared to simple button controls.

5. Manufacturer Support and Geographic Factors

Brand authority affects pricing. Manufacturers like Rumtoo prioritize engineering integrity and after-sales support. While sourcing from an unverified supplier might seem cheaper, the lack of spare parts availability and technical guidance often leads to higher long-term operational costs. Shipping logistics, especially for large 40-foot container loads needed for complete lines, also contribute to the landed cost of the equipment.

Summary

Selecting the right Plastic Pelletizer Machine involves a trade-off between initial capital expenditure and long-term operational efficiency. By defining your material type (film vs. rigid) and target throughput, you can select a system with the appropriate specs. Investing in quality components and proven technology ensures that your recycling line remains profitable for years to come.