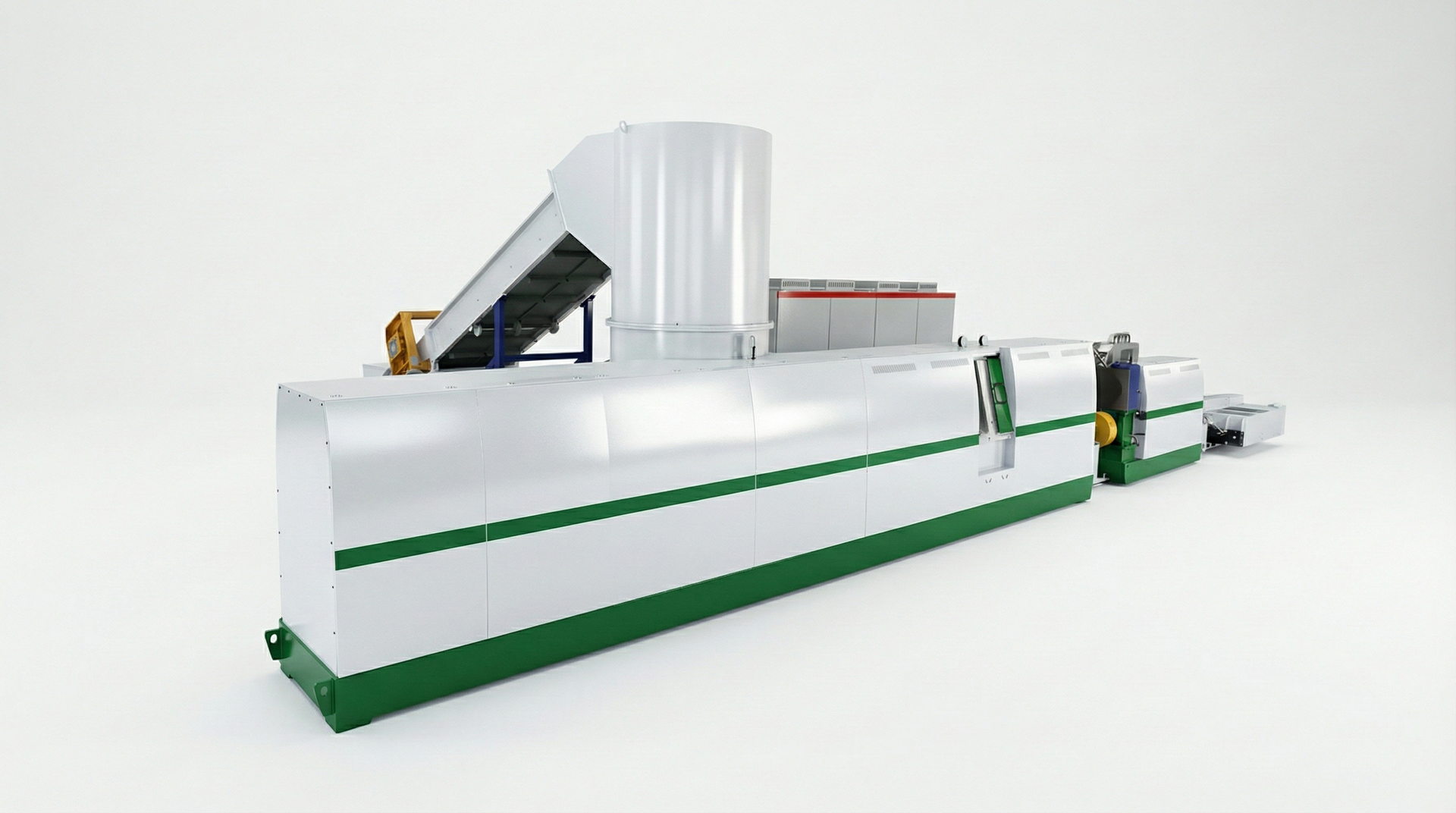

Efficient EPS Foam Granulating Machine

Our EPS Styrofoam granulating line is essential for recycling expanded polystyrene. It processes large volumes of EPS waste, transforming it into reusable granules for new products, significantly boosting environmental sustainability by reducing landfill waste.

Core Benefits of Our Granulating Line

- High Output & Efficiency

Processes large volumes of EPS waste quickly with minimal energy consumption.

- Significant Volume Reduction

Dramatically reduces the volume of EPS waste, making storage and transport more economical.

- Resource Conservation

Allows for the reuse of EPS, conserving valuable resources and reducing raw material costs.

- Creates Economic Value

Transforms bulky waste into a valuable recycled material that can be sold or reused in manufacturing.

Simple & Efficient Working Process

Our streamlined process efficiently converts bulky EPS foam into dense, reusable granules in just a few key steps.

- 1. Feeding & Pre-Crushing

Large pieces of EPS foam waste are fed into the system. An optional pre-crusher breaks them down into a more manageable size for optimal processing.

- 2. Granulating & Shredding

The heart of the line, the granulator, shreds the EPS foam into small, uniform granules, significantly reducing its volume.

- 3. Collection & Storage

The final, dense granules are collected and bagged. They are now a valuable, easy-to-store raw material, ready for transportation or reuse in new products.

Applications & Suitable Materials

Built for bulky foam waste streams, the line turns lightweight materials into dense, reusable granules for downstream manufacturing.

- EPS Packaging Foam

Appliance packaging, protective inserts, cushioning blocks, and loose-fill foam.

- XPS / Insulation Boards

Insulation offcuts and boards can be reduced and processed for recycling.

- EPE / Foam Sheets

Foam sheets, rolls, and trims can be compacted into denser, easier-to-handle material.

- Recycled Granules Output

Produces uniform granules suitable for new foam products, molding, or compounding.

Image Gallery

Choosing The Right Production Line

Consider these key factors to ensure you select the perfect EPS granulating solution for your operational needs.

- Capacity Requirements

The volume of EPS waste you need to process per hour or day.

- Desired Granule Size

The final size of the granules required for your intended application.

- Space Availability

The physical space available at your facility for installation.

- Budget & Investment

The overall cost of the equipment, installation, and operation.

Frequently Asked Questions

Recycled EPS granules are highly versatile and can be used to manufacture a wide range of products, including picture frames, construction materials like insulation panels, coat hangers, and new packaging materials.

Our machines are designed for user-friendly operation. We provide comprehensive training and documentation. Maintenance is straightforward, with easy access to key components and readily available spare parts to ensure maximum uptime.

By granulating bulky EPS foam, the machine diverts huge volumes of non-biodegradable waste from landfills. It turns this waste into a valuable resource, promoting a circular economy, conserving raw materials, and reducing the carbon footprint associated with waste transport.

Capacity depends on your daily foam volume, material type (EPS/XPS/EPE), and feeding method. Share your target throughput and available floor space, and we’ll recommend the best configuration.

We support common industrial power standards (customizable to your country). Provide your voltage/frequency and site layout, and we’ll confirm wiring, footprint, and auxiliary equipment requirements.

Yes. We offer remote or on-site commissioning options, operator training, and a recommended spare-parts list to keep your line running with minimal downtime.

Warranty & Support

- 1-Year Limited Warranty

All of our recycling machines come with a one-year limited warranty, covering key components and providing you with peace of mind.

- Expert Support & Customization

Our team provides expert guidance to help you choose the right capacity and configuration. All our production lines can be customized to meet your specific requirements.

Inquire Now

Discover more about how our technology can enhance your recycling efficiency and sustainability practices today.