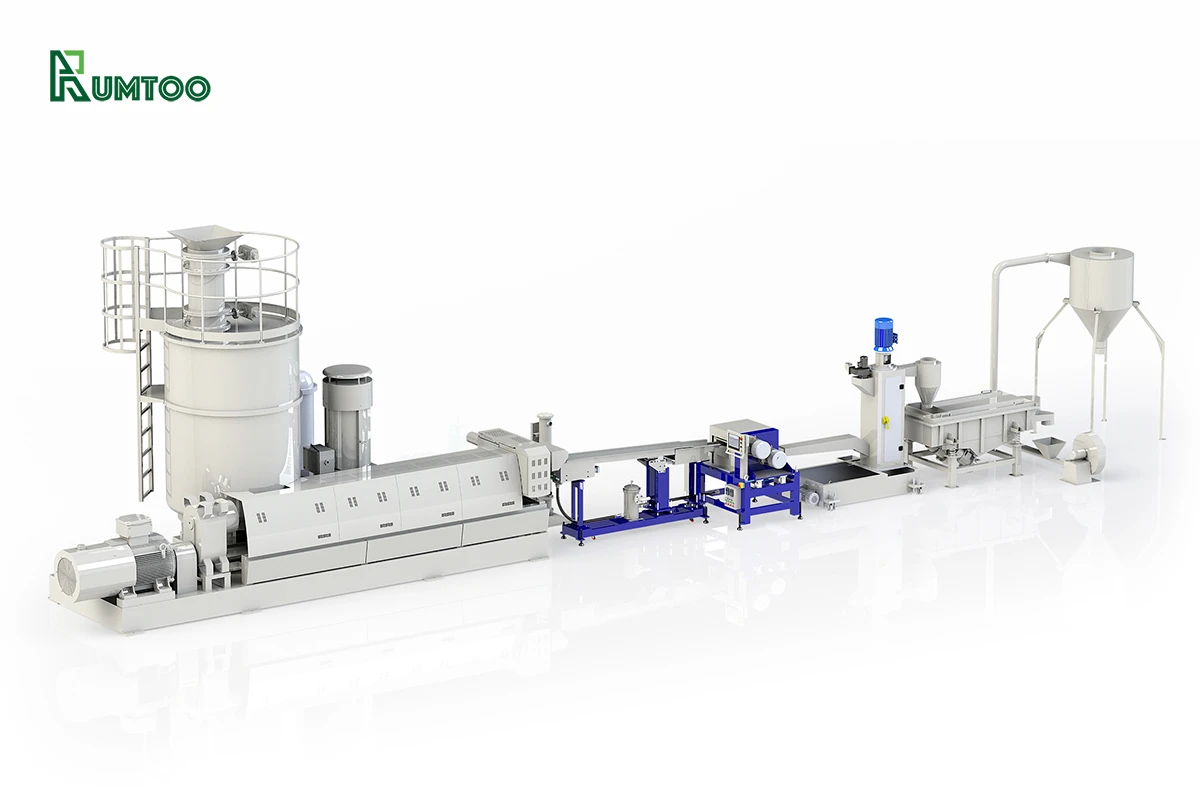

Water Ring Pelletizer for PP and PE Plastic Film/Woven Bags

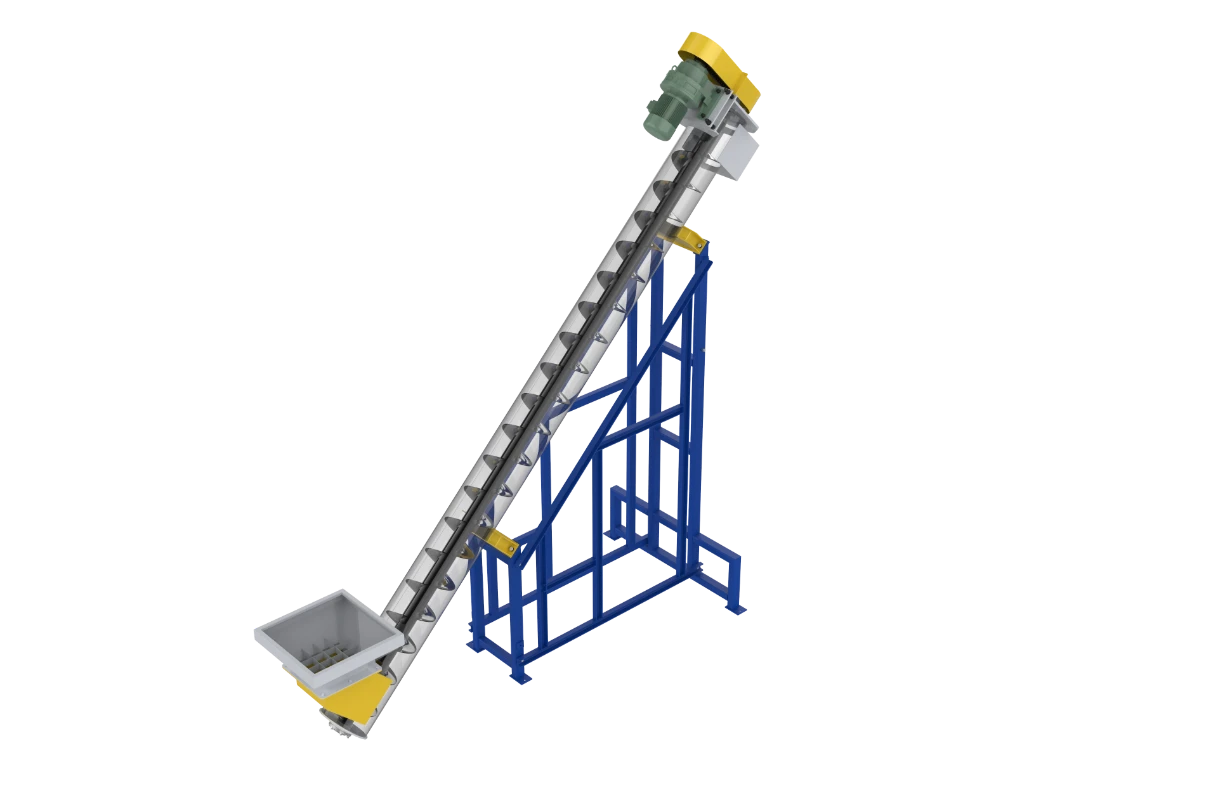

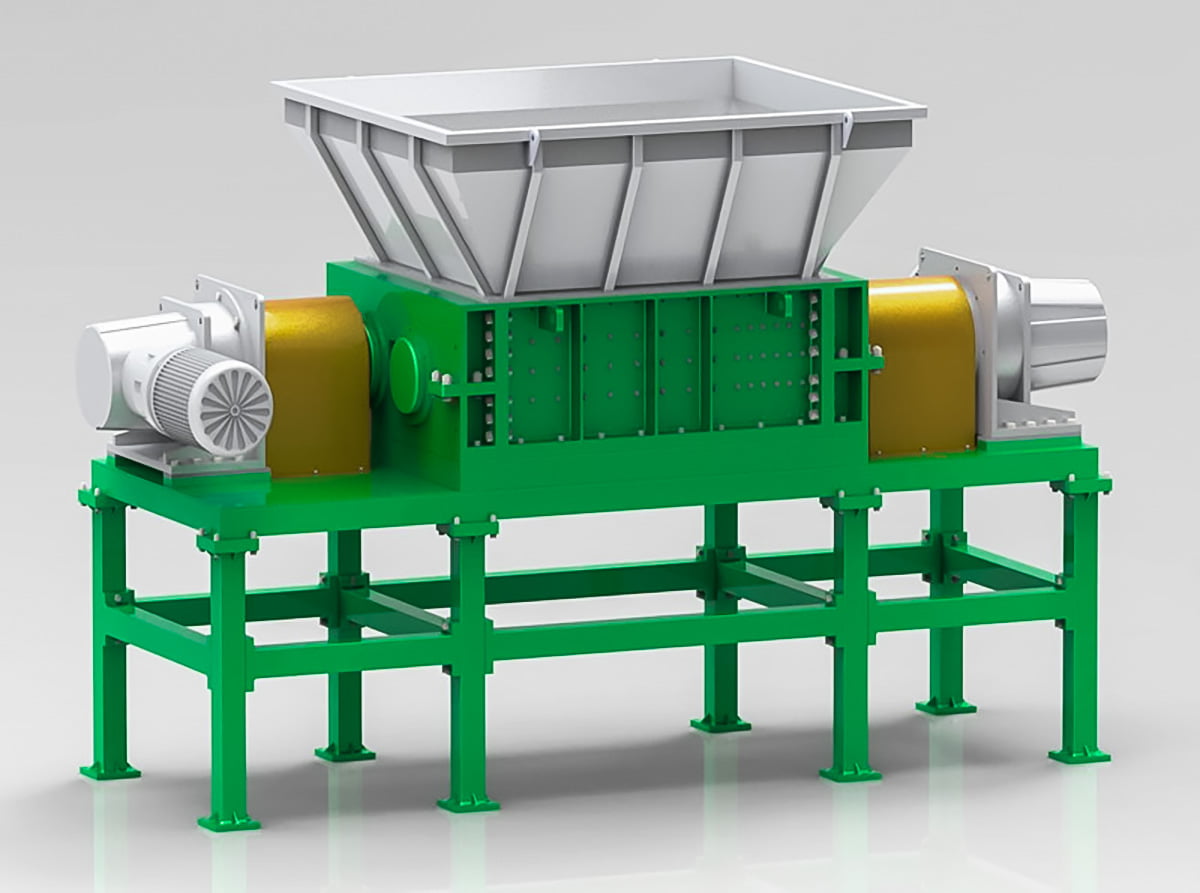

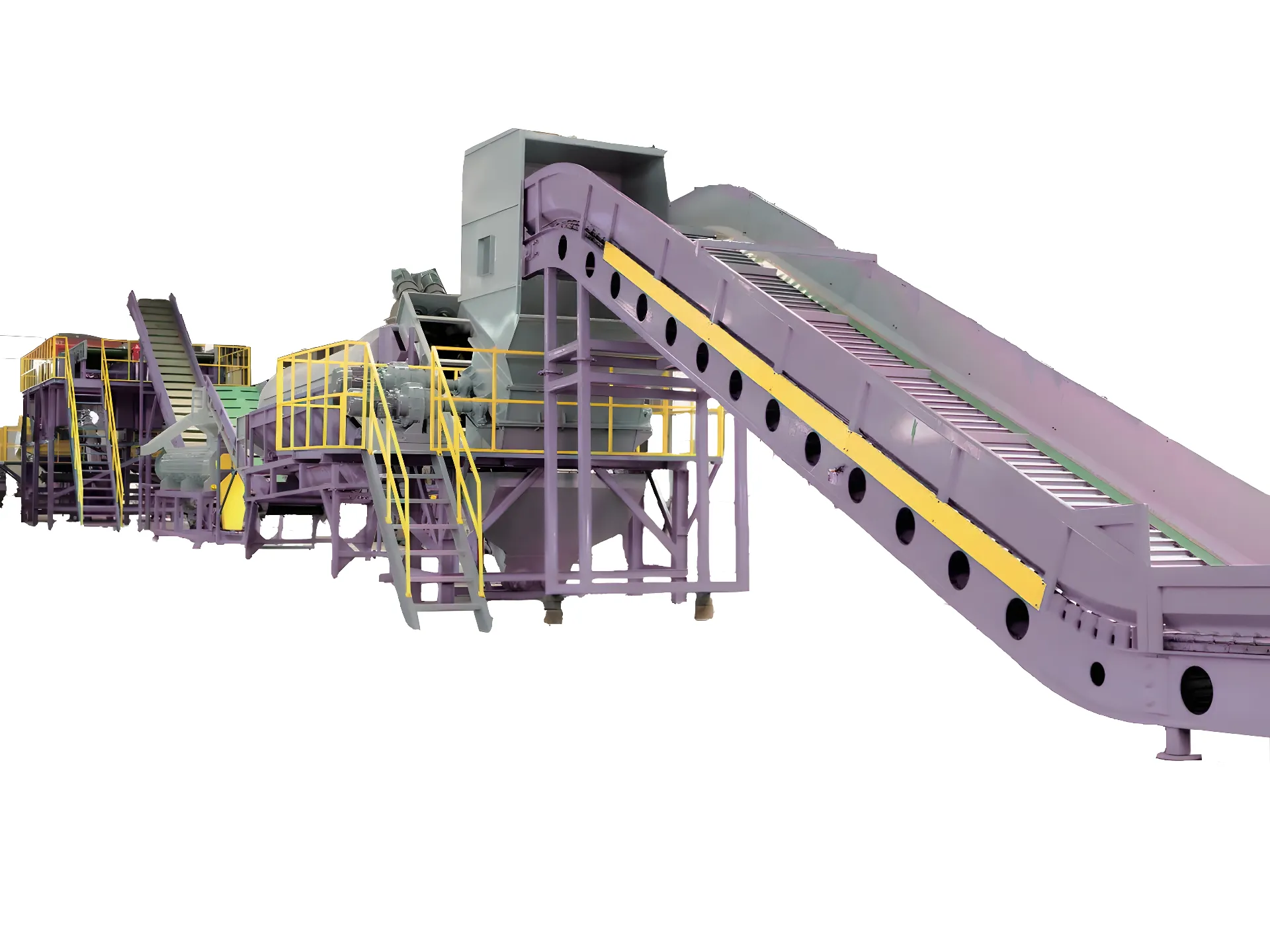

Introduction The recycling of PP and PE plastic films and woven bags has always been a complex process, requiring multiple steps and machines. The Water Ring Pelletizer for Clean PP and PE Plastic Film/Woven Bags is an advanced so...