DAF and Water Treatment Technologies: A Guide for Plastic Recycling and Industrial Applications

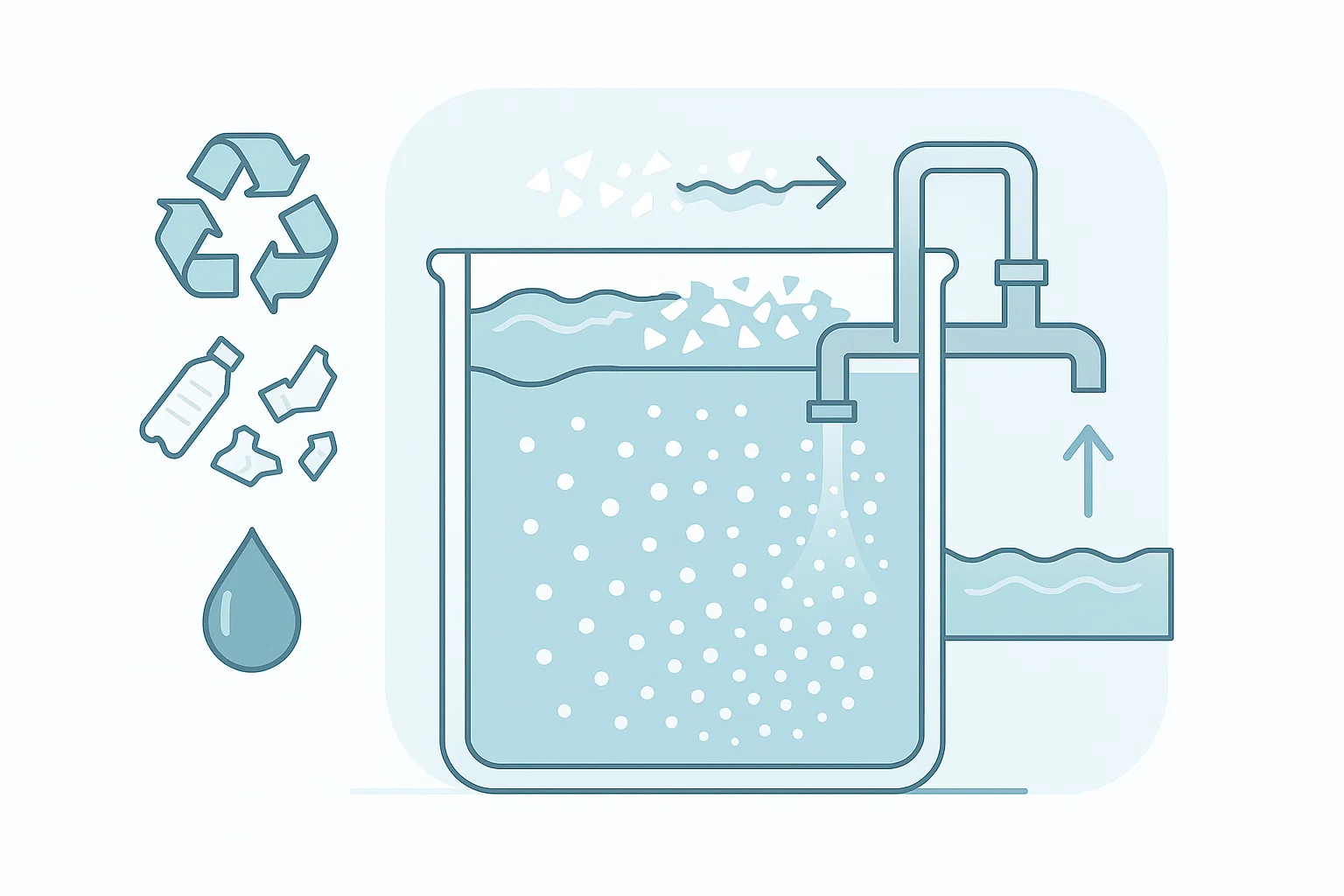

Water treatment has always been a critical aspect of many industrial processes, especially in plastic recycling, where wastewater management plays an essential role in maintaining environmental sustainability. Among the various te...

_7.webp)