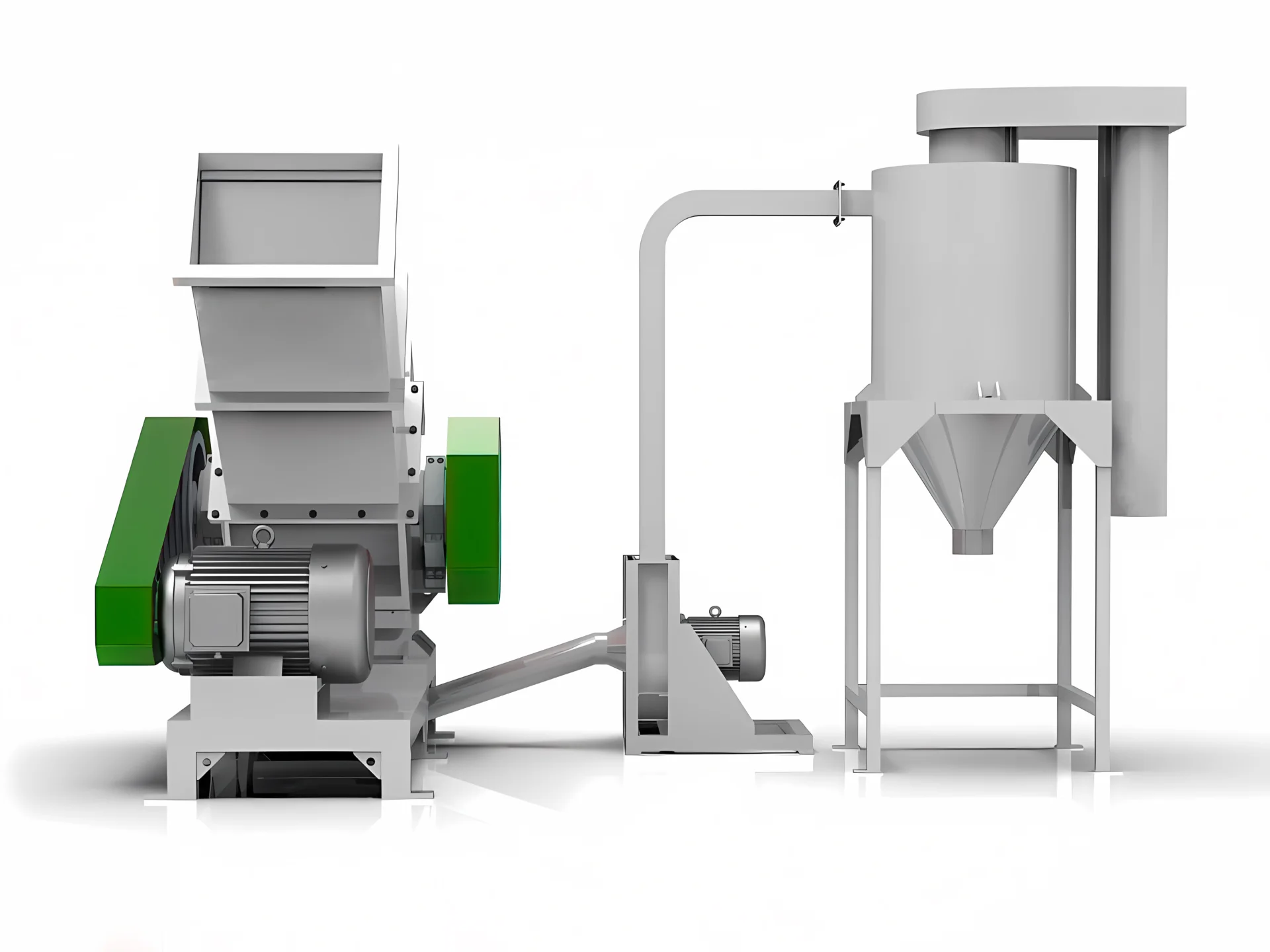

High-Efficiency Crusher for PVC Pipes & Profiles

Specifically designed for the challenges of long and bulky materials. Our crusher provides consistent, high-volume output with minimal maintenance, streamlining your recycling workflow.

Key Features That Drive Performance

Discover the engineering advantages that set our PVC Pipe Crusher apart.

Unmatched Throughput

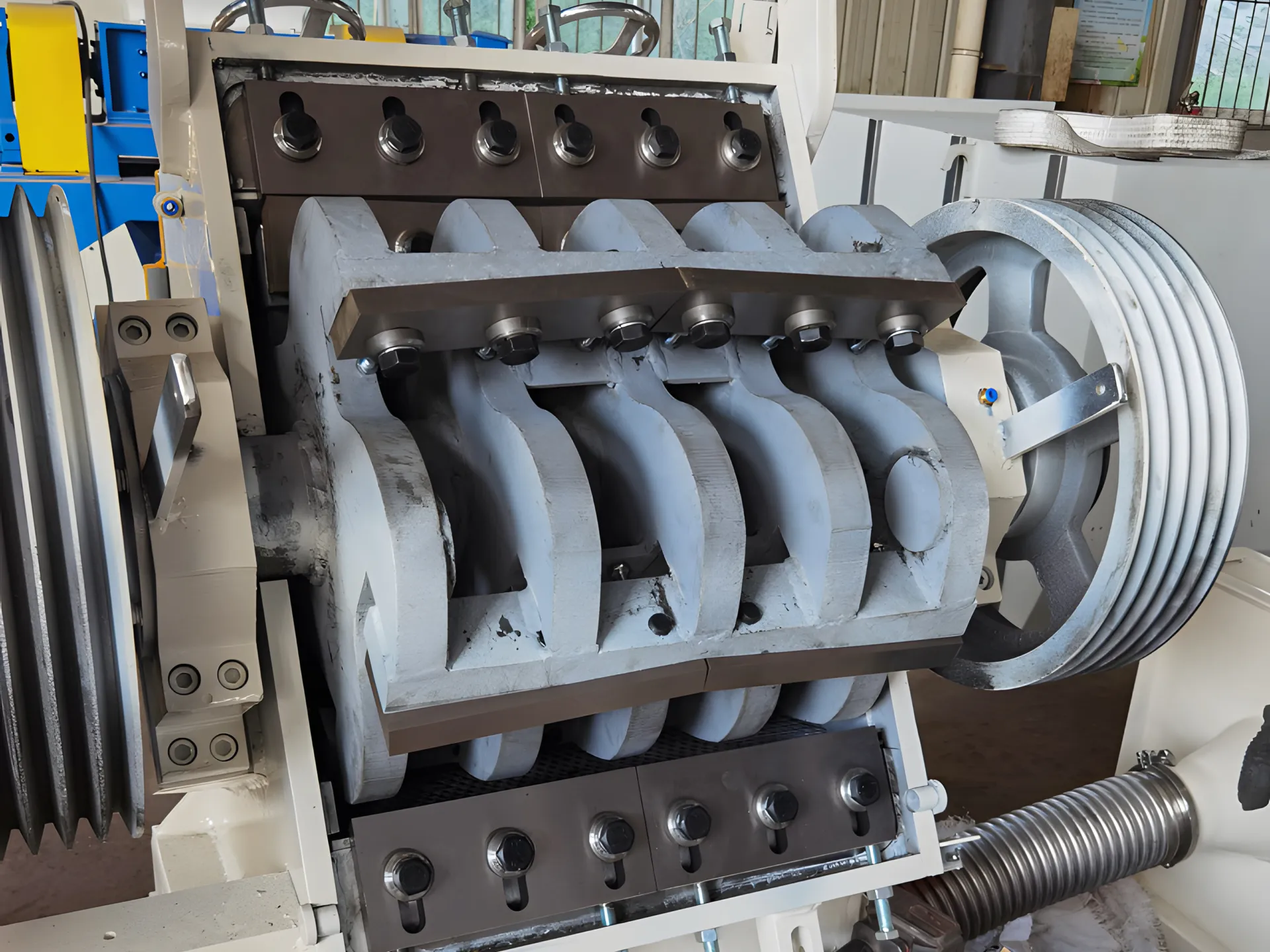

Featuring an innovative splayed, shear-type ladder knife design, our crusher significantly reduces cutting resistance, leading to higher processing speeds and lower energy bills.

Unyielding Durability

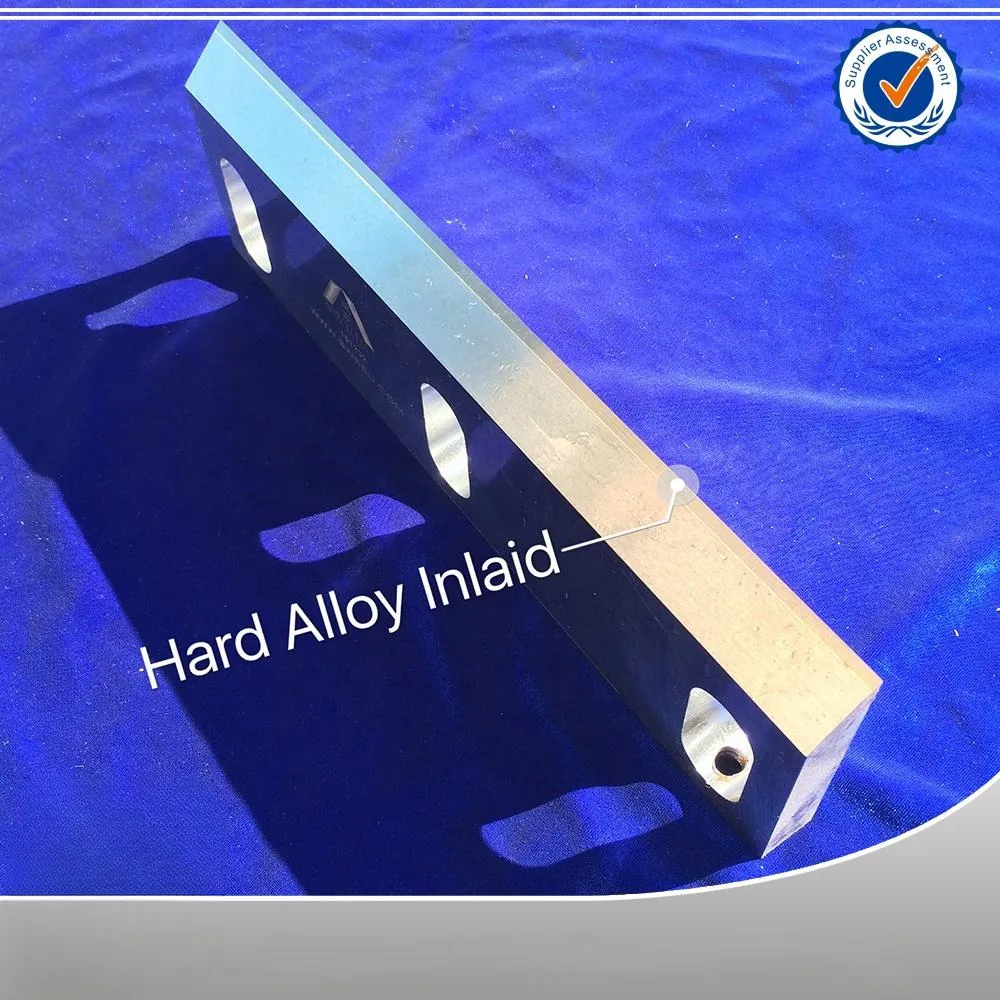

Built with premium imported blades and a robust structure to minimize downtime and extend the service life far beyond industry norms.

Superior Versatility

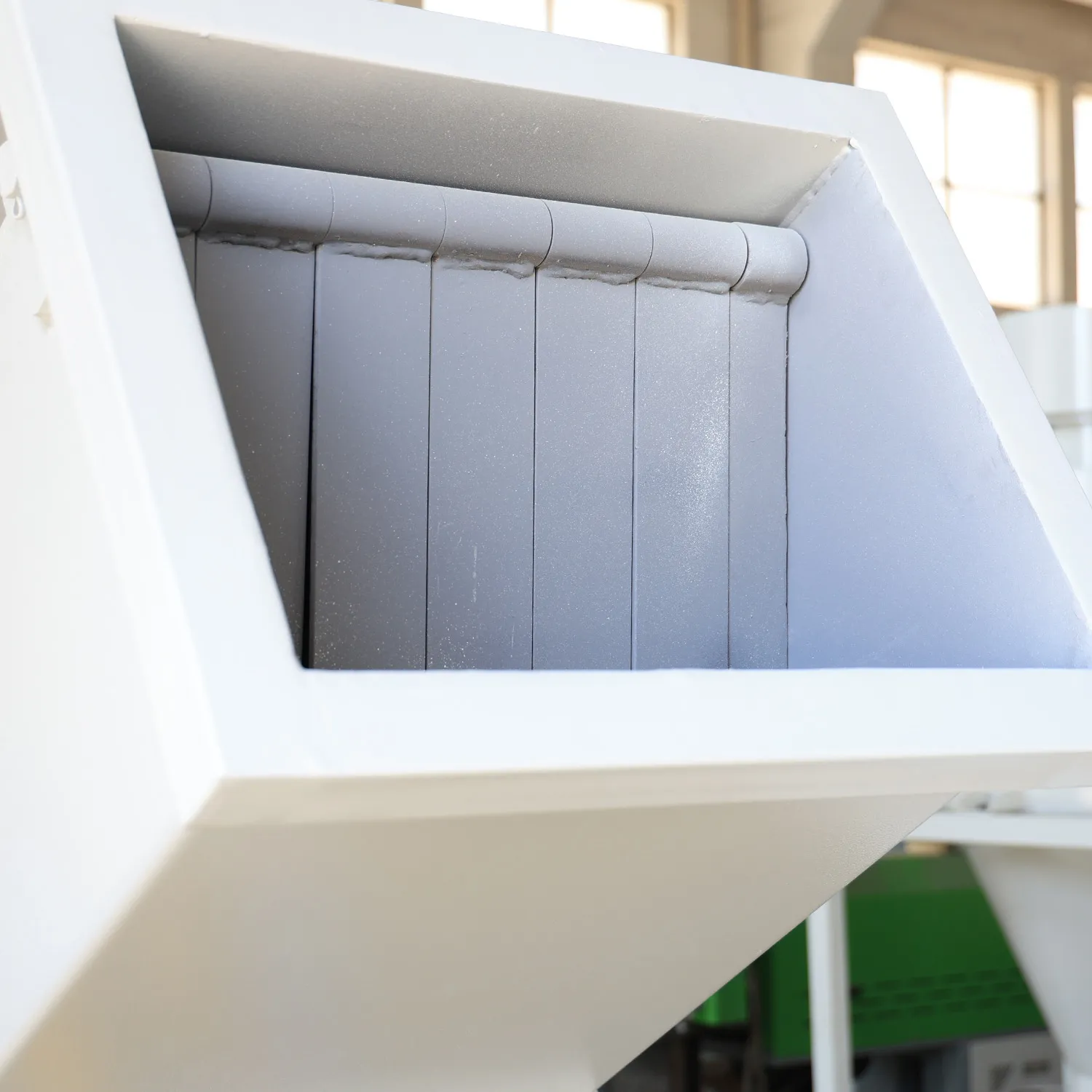

The specially engineered sloped hopper effortlessly handles long pipes and bulky profiles without jamming, eliminating the need for pre-cutting.

From Pipe to Flake in 3 Simple Steps

01. FEEDING

Whole PVC pipes or profiles are fed into the long, sloped hopper for continuous, hands-free operation.

02. CRUSHING

High-speed rotating blades shear the material against fixed blades, creating uniform pieces.

03. OUTPUT

Crushed flakes pass through a screen and are discharged, ready for the next recycling stage.

Advanced Engineering for Peak Performance

- Shear-Type Cutting Action: Minimizes dust, reduces power consumption, and produces more uniform particle sizes for easier downstream processing.

- Blockage-Free Hopper: Purpose-built for long materials, it uses gravity for consistent feeding, allowing for single-pass processing of entire pipes or profiles.

- Externally Mounted Bearings: A critical design feature that places bearings outside the crushing chamber, preventing contamination and drastically extending their life.

- Vibration-Dampening Structure: The heavy-duty, welded steel frame ensures smooth, stable performance, enhanced operator safety, and reduced wear on all components.

Applications

Designed for long and bulky rigid plastics — ideal for pipe and profile recycling lines.

PVC Pipe Recycling

Handle long PVC pipes directly with the horizontal hopper — suitable for production scrap and post-industrial pipes.

PVC Profiles

Window/door profiles, siding, and extrusion trim. Shear cutting helps produce uniform flakes for washing or re-extrusion.

Corrugated Pipes

Large-diameter corrugated pipes and bulky shapes — stable feeding with reduced jamming risk.

Boards & Rigid Scrap

Rigid sheets/boards and mixed rigid offcuts. Optional screens control the output size for downstream processing.

See It In Action

Detailed Technical Specifications

| Model | Power (kW) | Speed (rpm) | Rotor Diameter (mm) | Hopper Volume (m³) | Output (kg/h) |

|---|---|---|---|---|---|

| 560/630 | 22/37 | 2/4 | 500/550 | 0.3/0.5 | 250/350 |

| 730/830 | 55/75 | 4/4 | 600/800 | 0.5/1 | 450/700 |

| 1000/1300 | 90/110 | 4/6 | 900/1200 | 1/2 | 850/1200 |

Ready to Boost Your PVC Recycling Efficiency?

Our experts are standing by to help you select the perfect crusher model for your specific materials and capacity needs. Fill out the form below to receive a detailed proposal and pricing.

Frequently Asked Questions

What types of plastic can this machine handle?

Our crusher is optimized for a wide range of hard and soft plastics, including PVC, PE, and PP. It excels at processing bulky items like plastic pipes, window/door profiles, siding, boards, and large-diameter corrugated pipes.

How often do the blades need to be replaced or sharpened?

Thanks to the high-quality imported alloy steel and advanced heat treatment, the blades offer an exceptionally long service life. The exact sharpening frequency depends on the abrasiveness of the material and hours of operation, but they are designed for maximum longevity and can be re-sharpened multiple times to lower your maintenance costs.

What after-sales support do you provide?

We provide comprehensive support that includes detailed installation guidance, operational training for your team, and a full inventory of spare parts like blades and screens. Our technical support team is always ready to assist with any operational questions to ensure you achieve maximum uptime and productivity.

What is the final flake size and available screen options?

The final flake size is controlled by interchangeable screens. Standard screen sizes range from 20–60 mm, and custom screens can be supplied based on downstream washing or extrusion requirements.

What pipe diameter and length can be fed directly?

The horizontal hopper allows direct feeding of long PVC pipes and profiles without pre-cutting. Depending on the model, typical maximum pipe diameters range from 200–630 mm, while pipe length is generally not limited.

How do I choose the right model for my application?

Model selection depends on pipe diameter, wall thickness, target throughput, and downstream equipment. Our engineers will recommend the optimal rotor size and motor power based on your material details.

Warranty & Installation

We stand behind our equipment with robust support to ensure your peace of mind and operational success.

Comprehensive Warranty

Every machine comes with a 12-month full parts warranty. We guarantee all components to be free from defects in material and workmanship under normal use and service.

Global Installation Support

Our certified engineers provide on-site installation, commissioning, and operator training to ensure your team can operate the equipment safely and efficiently from day one.

Lifetime Technical Service

Beyond the warranty period, we offer lifetime technical support via phone, email, or video call, along with a ready supply of genuine spare parts to keep you running.