The escalating crisis of plastic waste demands innovative solutions that not only recycle but also contribute to a circular economy. The “Plastic Film Squeezer” stands out as a beacon of progress in this domain, offering a sustainable pathway for managing plastic film waste.

Bridging the Gap in Plastic Recycling

Plastic films, ubiquitous in packaging, pose significant recycling challenges due to their lightweight and moisture-retaining properties. Enter the Plastic Film Squeezer, a revolutionary technology designed to efficiently reduce moisture content in washed plastic films, facilitating their reuse and recycling. This process not only enhances the efficiency of recycling plants but also contributes to the reduction of plastic pollution globally.

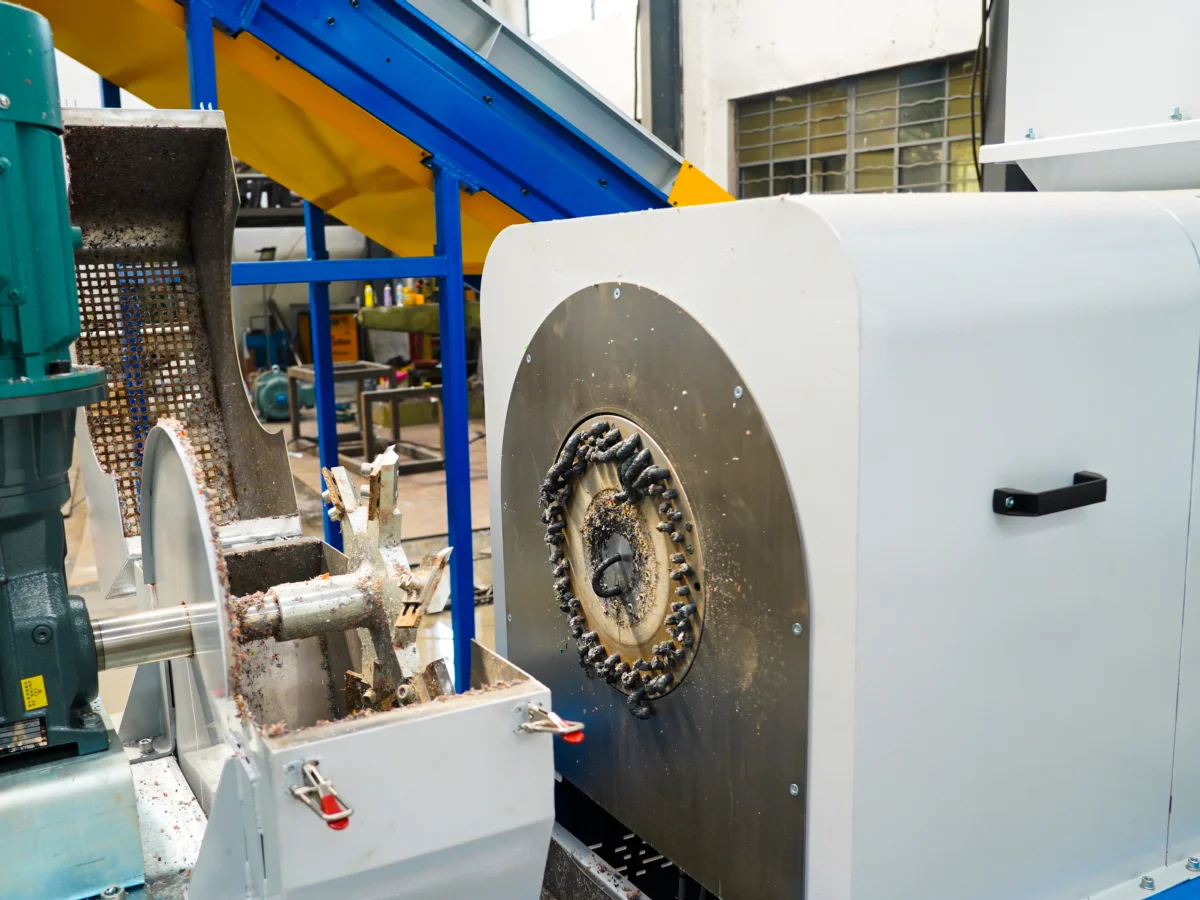

How It Works

The technology behind the Plastic Film Squeezer is fascinating. By employing a screw press mechanism, it effectively squeezes out moisture from plastic films. Subsequently, the films undergo a heating and densification process, transforming them into granules ready for reintegration into the production cycle. This method significantly lowers energy consumption compared to traditional drying techniques, marking a leap forward in sustainable recycling practices.

The Environmental Impact

The environmental benefits of the Plastic Film Squeezer cannot be overstated. By ensuring that plastic films can be recycled more efficiently, it helps divert vast amounts of waste from landfills and the natural environment. Moreover, the reduction in energy consumption during the drying process contributes to lower carbon emissions, aligning with global sustainability goals.

A Catalyst for the Circular Economy

The Plastic Film Squeezer exemplifies the principles of the circular economy, where waste materials are viewed as resources. Through its innovative recycling process, it supports the conversion of plastic film waste into valuable materials, thus closing the loop and reducing the need for virgin plastic production.

Economic Benefits

Adopting Plastic Film Squeezer technology not only has environmental advantages but also offers economic benefits. By improving the efficiency of the recycling process, it enables recycling facilities to handle higher volumes of material, increasing their operational capacity and profitability. This technology represents a win-win for both the environment and the economy.

Conclusion

The Plastic Film Squeezer is more than just a technological innovation; it is a pivotal component in the transition towards a more sustainable and circular economy. By improving the recycling process for plastic films, it plays a crucial role in reducing plastic waste, conserving resources, and paving the way for a greener future. As we continue to confront the plastic pollution crisis, technologies like the Plastic Film Squeezer offer hope and a path forward.

Let’s embrace this innovative technology and support initiatives that aim to reduce our environmental footprint, one plastic film at a time.

Frequently Asked Questions (FAQs)

How does the Plastic Film Squeezer contribute to the circular economy?

The Plastic Film Squeezer enhances recycling efficiency by drying plastic films, allowing them to be reused instead of disposed of, thus supporting the circular economy by turning waste into resources.

What types of plastic can the Plastic Film Squeezer process?

It is capable of processing a variety of plastic films, including LDPE, LLDPE, and PP woven bags, making it a versatile tool in the recycling industry.

What are the environmental benefits of using a Plastic Film Squeezer?

By reducing the moisture content in plastic films, it enables more efficient recycling, thereby decreasing landfill waste, conserving resources, and reducing greenhouse gas emissions from the production of new plastics.

Can the Plastic Film Squeezer improve recycling plant operations?

Yes, it increases the throughput of recycling operations by enabling faster and more efficient processing of plastic films, leading to economic benefits and higher profitability.

Is the technology behind the Plastic Film Squeezer energy-efficient?

Yes, it is designed to consume less energy than traditional drying methods, contributing to a reduction in overall energy usage in recycling facilities.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.

[contact-form-7 id=”c9499fe” title=”Contact form 2″]